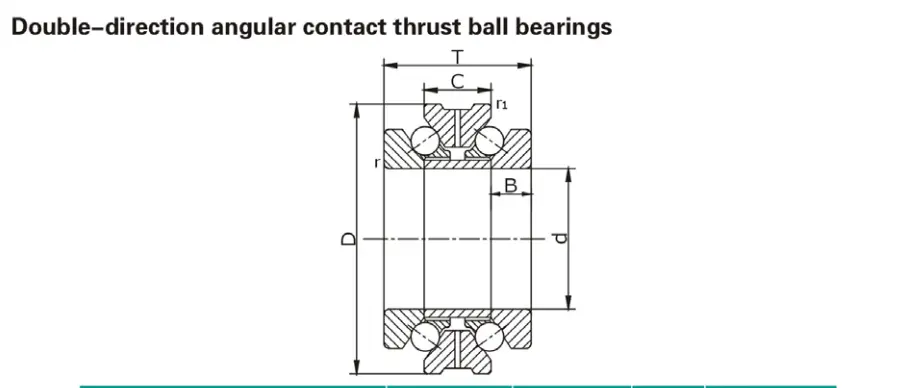

Double-Direction Angular Contact Thrust Ball Bearings

Outer Diameter: 1030-1720mm

Weight: 135-693kg

Type: 52000,38000

Double direction thrust ball bearings consist of three rings, along with two ball and cage assemblies. The two ball and cage assemblies are separated by the shaft washer.

Double direction thrust ball bearings are able to accommodate axial thrust loads in both directions. They are not able to tolerate any amount of radial load.

The balls which are used as rolling elements in this type of bearing enable outstanding performance at the highest speeds.

These bearings have a separable design to facilitate easy mounting, dismounting and bearing inspection. This also means that they are easily interchangeable.

Double-Direction Angular Contact Thrust Ball Bearings: Your Ultimate Guide

Welcome to CHG Bearing’s comprehensive guide on Double-Direction Angular Contact Thrust Ball Bearings! Whether you’re a purchasing manager, technical engineer, production manager, or company boss, understanding the ins and outs of these bearings can help you make informed decisions for your equipment and operations. Read on to discover what makes our bearings stand out and how they can benefit your industrial needs.

What is a Double-Direction Angular Contact Thrust Ball Bearing?

A Double-Direction Angular Contact Thrust Ball Bearing is a specialized type of bearing designed to support axial loads in both directions. Unlike standard bearings, these bearings are engineered to handle high thrust loads with precision and stability, making them ideal for applications where the direction of the load can change frequently.

Key Features:

- Dual-direction Load Support: Capable of handling axial loads in both directions.

- Angular Contact Design: Offers superior load distribution and reduced friction.

- High Precision: Ensures smooth operation and minimal vibration.

These bearings are crucial for equipment in the metallurgical and mining industries, where precision and durability are paramount.

CHG Bearing: Your Trusted Partner in Bearing Solutions

CHG Bearing is a leading manufacturer and supplier of Double-Direction Angular Contact Thrust Ball Bearings. Here’s why you should choose us:

Customization and Solutions: We offer tailored solutions to meet the specific demands of different working conditions. Our bearings can be customized in terms of size, material, and lubrication to ensure optimal performance in your unique applications.

30 Years of Expertise: With over three decades in the industry, we’ve collaborated with numerous large companies, bringing extensive experience and reliability to our products.

Innovative Excellence: We hold more than 50 invention patents and have achieved ISO9001 and ISO14001 certifications, demonstrating our commitment to quality and environmental management.

For personalized assistance, feel free to contact us at sale@chg-bearing.com.

Technical Specifications

| Specification | Details |

|---|---|

| Type | Double-Direction Angular Contact Thrust Ball Bearing |

| Material | High-grade Chrome Steel or Customized Materials |

| Load Capacity | Varies based on size and application |

| Speed Rating | High-speed applications available |

| Temperature Range | Designed to withstand extreme temperatures |

| Customization | Available in various sizes and configurations |

Benefits of Double-Direction Angular Contact Thrust Ball Bearings

- Enhanced Load Support: Capable of bearing heavy loads in both axial directions, reducing equipment strain and increasing lifespan.

- Improved Precision: The angular contact design allows for high accuracy and stability, which is critical in high-speed and high-load applications.

- Durability: Built to withstand harsh environments and extreme operating conditions, minimizing the need for frequent replacements.

Applications

Double-Direction Angular Contact Thrust Ball Bearings are widely used in:

- Metallurgical Equipment: Blast furnaces, rolling mills, and steelmaking equipment.

- Mining Machinery: Jaw crushers, impact crushers, vibrating screens, and feeders.

- Industrial Machinery: Precision machinery where high load capacity and accuracy are required.

Installation Guide

- Preparation: Ensure the mounting surfaces are clean and free of debris.

- Alignment: Properly align the bearings with the shaft and housing to prevent uneven wear.

- Mounting: Use appropriate tools to avoid damaging the bearing during installation.

- Lubrication: Apply recommended lubrication to ensure smooth operation.

For detailed installation procedures, refer to the manufacturer’s guidelines or contact our support team.

Maintenance and Care

- Regular Inspections: Check for signs of wear or damage periodically.

- Proper Lubrication: Maintain proper lubrication levels to ensure longevity and performance.

- Avoid Overloading: Ensure that the bearings are used within their specified load limits to prevent premature failure.

FAQ

Q: What industries benefit the most from them?

A: They are particularly valuable in the metallurgical and mining industries due to their high load capacity and precision.

Q: Can these bearings be customized?

A: Yes, CHG Bearing offers customization options to fit specific needs and applications.

Q: How often should I replace these bearings?

A: The lifespan of the bearings depends on operating conditions. Regular maintenance and inspections will help determine when replacement is necessary.

Customer Reviews

"The Double-Direction Angular Contact Thrust Ball Bearings from CHG Bearing have significantly improved our equipment’s performance. Their precision and durability are unmatched!" – John D., Production Manager

"Excellent product and service! The customization options were exactly what we needed for our unique applications." – Emily R., Technical Engineer

Contact Us

For more information or to discuss your specific requirements, contact us today at sale@chg-bearing.com. Our team is here to assist you with any inquiries or support you may need.

Thank you for choosing CHG Bearing! We look forward to providing you with top-quality bearings that meet your highest standards.

| Boundary dimensions | Basic load ratings | Designations | Mass | Limiting speeds | ||||||||

| mm | kN | kg | r/min | |||||||||

| d | D | T | C | B | rmin | r1min | Ca | Coa | Grease | oil | ||

| 140 | 190 | 60 | 30 | 15 | 1.5 | 1 | 91.5 | 365 | 234928 | 4.2 | 2000 | 2800 |

| 210 | 84 | 42 | 21 | 2.1 | 0.6 | 145 | 525 | 234428 | 8.75 | 1800 | 2600 | |

| 150 | 210 | 72 | 36 | 18 | 2 | 1 | 116 | 465 | 234930 | 6.6 | 1800 | 2400 |

| 225 | 90 | 45 | 22.5 | 2.1 | 0.6 | 172 | 620 | 234430 | 10.7 | 1700 | 2400 | |

| 160 | 220 | 72 | 36 | 18 | 2 | 1 | 118 | 490 | 234932 | 7 | 1700 | 2400 |

| 240 | 96 | 48 | 24 | 2.1 | 0.6 | 185 | 680 | 234432 | 13 | 1600 | 2200 | |

| 170 | 230 | 72 | 36 | 18 | 2 | 1 | 120 | 520 | 234934 | 7.35 | 1600 | 2200 |

| 260 | 108 | 54 | 27 | 2.1 | 0.6 | 218 | 810 | 234434 | 17.7 | 1500 | 2000 | |

| 180 | 250 | 84 | 42 | 21 | 2 | 1 | 158 | 655 | 234936 | 10.7 | 1500 | 2000 |

| 280 | 120 | 60 | 30 | 2.1 | 0.6 | 281 | 1020 | 234436 | 23.4 | 1400 | 1900 | |

| 190 | 260 | 84 | 42 | 21 | 2 | 1 | 161 | 695 | 234938 | 11 | 1400 | 2000 |

| 290 | 120 | 60 | 30 | 2.1 | 0.6 | 285 | 1060 | 234438 | 24.4 | 1300 | 1800 | |

| 200 | 280 | 96 | 48 | 24 | 2 | 1 | 204 | 855 | 234940 | 15.7 | 1300 | 1800 |

| 310 | 132 | 66 | 33 | 2.1 | 0.6 | 315 | 1180 | 234440 | 31.5 | 1200 | 1700 | |

| 220 | 300 | 96 | 48 | 24 | 2 | 1 | 210 | 930 | 234944 | 17 | 1200 | 1700 |

| 340 | 144 | 72 | 36 | 3 | 1 | 360 | 1390 | 234444 | 41 | 1100 | 1500 | |

| 240 | 320 | 96 | 48 | 24 | 2 | 1 | 213 | 980 | 234948 | 18.3 | 1100 | 1500 |

| 360 | 144 | 72 | 36 | 3 | 1 | 360 | 1450 | 234448 | 44 | 1000 | 1400 | |

| 260 | 360 | 120 | 60 | 30 | 2 | 1 | 315 | 1390 | 234952 | 30 | 1000 | 1400 |

| 400 | 164 | 82 | 41 | 3 | 1.5 | 440 | 1890 | 234452 | 64.5 | 900 | 1300 | |

| 280 | 380 | 120 | 60 | 30 | 2 | 1 | 320 | 1470 | 234956 | 33.5 | 900 | 1300 |

| 420 | 164 | 82 | 41 | 3 | 1.5 | 440 | 1960 | 234456 | 68 | 850 | 1200 | |

| 300 | 420 | 144 | 72 | 36 | 3 | 1 | 395 | 1810 | 234960 | 53 | 850 | 1200 |

| 320 | 440 | 144 | 72 | 36 | 3 | 1 | 405 | 1920 | 234964 | 55.5 | 800 | 1100 |

| 340 | 460 | 144 | 72 | 36 | 3 | 1.1 | 415 | 2020 | 234968 | 58.5 | 750 | 1000 |

| 360 | 480 | 144 | 72 | 36 | 3 | 1.1 | 420 | 2130 | 234972 | 61.5 | 710 | 950 |

| 380 | 520 | 164 | 82 | 41 | 4 | 1.5 | 485 | 2560 | 234976 | 87.5 | 630 | 900 |

| 400 | 540 | 164 | 82 | 41 | 4 | 1.5 | 495 | 2700 | 234980 | 91.5 | 600 | 850 |