4 Point Contact Ball Bearing

Outer Diameter: 225-870mm, Weight: 5.1-470kg

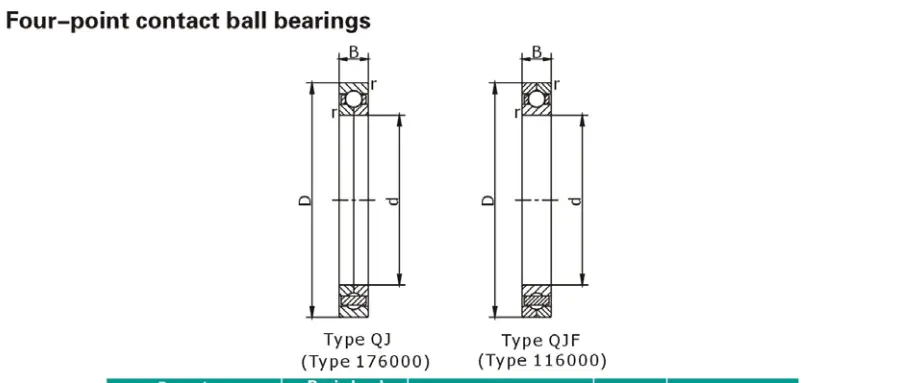

2. Type: QJ, QJF

3. Feature: Four point contact ball bearings are separable bearings, in which, type QJ0000 has two piece inner ring, type QJF0000 has two piece outer rings, their contact angle are both 35°. When carrying pure radial loads, each ball cotacts with rings ar four point, and they are two point contact under pure axial loads. The bearings can carry axial loads in two directions and certain moment loads, and have the features of single row and double row angular contact ball bearings. They only can work normally in high speed when two point contact is formed.

4. Cage: Brass or aluminium soild cages are exactly suitbale for four point contact ball bearings.

5. Material: GCr15/GCr15SiMn/G20Cr2Ni4A

4 Point Contact Ball Bearing: Your Comprehensive Guide

What is a 4 Point Contact Ball Bearing?

A specialized kind of bearing called a 4 Point Contact Ball Bearing is made to handle both radial and axial loads in various applications. The 4 point contact design, in contrast to conventional ball bearings, which typically accommodate radial loads, permits four points of contact between the ball and the raceway, accommodating higher axial loads in both directions. Because of this, it is ideal for applications that require robustness and high precision.

Key Features:

- 4-Point Contact: Provides support for axial loads in both directions.

- High Precision: Ensures smooth and reliable operation in demanding conditions.

- Durability: Built to withstand high loads and harsh environments.

CHG Bearing: Your Trusted 4 Point Contact Ball Bearing Manufacturer

We are proud to be a leading manufacturer and supplier of 4 Point Contact Ball Bearing at CHG Bearing. We have a reputation for providing high-quality products and solutions that are tailored to various working conditions with over 30 years of industry experience.

Why Choose CHG Bearing?

- Customization and Solutions: We offer tailored solutions for different operational needs, ensuring that our bearings meet the specific requirements of your equipment and environment.

- Proven Experience: Our extensive experience includes partnerships with numerous large companies, demonstrating our capability and reliability in the industry.

- Innovative Technology: With more than 50 invention patents, we are at the forefront of technological advancements in bearing design and manufacturing.

- Certified Quality: We adhere to stringent quality standards, having passed ISO9001 quality management system and ISO14001 environmental management system certifications.

For inquiries or to discuss your specific needs, please contact us at sale@chg-bearing.com.

Technical Specifications

| Feature | Specification |

|---|---|

| Type | 4 Point Contact Ball Bearing |

| Load Capacity | High axial and radial loads |

| Precision | P0 /P6 /P5 /P4 /P2 |

| Material | Chrome Steel, Stainless Steel, Ceramic |

| Temperature Range | Up to 200°C |

| Lubrication | Grease, Oil, or Custom |

| Certifications | ISO9001, ISO14001 |

4 Point Contact Ball Bearing Benefits

- Enhanced Load Capacity: Capable of handling both radial and axial loads with ease.

- Reduced Maintenance: Long-lasting performance reduces the need for frequent replacements.

- Precision Engineering: Ensures accurate and reliable operation even in complex applications.

- Versatility: Suitable for a wide range of industries including metallurgy and mining.

Applications

It is versatile and find applications in various industries:

- Metallurgical Equipment: Used in blast furnaces, rolling mills, and steelmaking equipment.

- Mining Machinery: Ideal for jaw crushers, impact crushers, and vibrating screens.

- General Industrial Equipment: Suitable for use in various machinery requiring high load-bearing capabilities.

Installation Guide

- Preparation: Ensure the bearing and housing are clean and free from debris.

- Alignment: Properly align the bearing with the housing to avoid misalignment.

- Insertion: Gently press the bearing into the housing using appropriate tools to avoid damage.

- Lubrication: Apply the recommended lubricant based on your application needs.

- Testing: After installation, check the bearing for proper operation and alignment.

Maintenance and Care

- Regular Inspection: Check for signs of wear, such as noise or vibration.

- Lubrication: Ensure that bearings are properly lubricated according to manufacturer recommendations.

- Cleaning: Keep the bearings and surrounding area clean to prevent contamination.

- Replacement: Replace bearings if they show signs of significant wear or damage.

FAQ

1. What makes 4 Point Contact Ball Bearings different from other bearings?

4 Point Contact Ball Bearing can handle both radial and axial loads in multiple directions, unlike standard ball bearings which are primarily designed for radial loads.

2. How do I choose the right bearing for my application?

Consider factors like load requirements, operating environment, and precision needs. Consulting with a bearing specialist can help ensure you select the appropriate product.

3. What is the typical lifespan of a 4 Point Contact Ball Bearing?

Lifespan can vary based on application conditions, but regular maintenance and proper lubrication can significantly extend bearing life.

4. Can CHG Bearing customize bearings for specific applications?

Yes, CHG Bearing offers customization options to meet unique operational requirements and conditions.

Customer Reviews

- "CHG Bearing's 4 Point Contact Ball Bearing have been a game-changer for our operations. Their reliability and performance are unmatched." – John D., Production Manager

- "The customization options provided by CHG have perfectly met our demanding requirements. Highly recommended!" – Sarah M., Technical Engineer

Contact Us

Contact us at: for additional information or to place an order. sale@chg-bearing.com. We are eager to assist you with your bearing requirements!

| Boundary dimensions | Basic load ratings | Part number | Mass | Installation dimersion | Limiting speeds | ||||||||

| mm | kN | Current | Original | kg | mm | r/min | |||||||

| d | D | B | rmin | Cr | Cor | damin | Damax | ramax | Grease | Oil | |||

| 120 | 180 | 28 | 2 | 148 | 196 | QJ1024 | 2.65 | 130 | 170 | 2 | 2600 | 3600 | |

| 215 | 40 | 2.1 | 286 | 340 | QJ224 | 6.95 | 132 | 203 | 2 | 2200 | 3200 | ||

| 260 | 55 | 3 | 390 | 490 | QJ324 | 16 | 148 | 292 | 3 | 1900 | 2800 | ||

| 130 | 200 | 33 | 3 | 182 | 240 | QJ1026 | 4.05 | 140 | 190 | 2 | 2200 | 3200 | |

| 230 | 40 | 3 | 296 | 365 | QJ226 | 7.75 | 144 | 216 | 2.5 | 1900 | 2800 | ||

| 280 | 58 | 4 | 423 | 560 | QJ326 | 19.5 | 148 | 262 | 3 | 1800 | 2600 | ||

| 140 | 210 | 22 | 1.1 | 121 | 163 | 605647A | 2.6 | 147 | 203 | 1 | 2000 | 3000 | |

| 210 | 33 | 2 | 190 | 265 | QJ1028 | 4.3 | 150 | 200 | 2 | 2000 | 3000 | ||

| 250 | 42 | 3 | 325 | 440 | QJ228 | 9.85 | 154 | 236 | 2 | 1800 | 2600 | ||

| 300 | 62 | 4 | 468 | 640 | QJ328 | 24 | 158 | 282 | 3 | 1700 | 2400 | ||

| 150 | 225 | 35 | 2.1 | 225 | 275 | QJ1030 | 176130 | 5.1 | 162 | 213 | 2 | 1900 | 2800 |

| 270 | 45 | 3 | 302 | 372 | QJ230 | 176230 | 12.5 | 164 | 256 | 2.5 | 1700 | 2400 | |

| 320 | 65 | 4 | 494 | 710 | QJ330 | 176330 | 29 | 168 | 302 | 2 | 1600 | 2200 | |

| 160 | 240 | 38 | 2.1 | 260 | 318 | QJ1032 | 176132 | 6.3 | 172 | 228 | 2 | 1800 | 2600 |

| 290 | 48 | 3 | 352 | 455 | QJ232 | 176232 | 14.6 | 174 | 276 | 2.5 | 1600 | 2200 | |

| 340 | 68 | 4 | 585 | 865 | QJ332 | 176332 | 31 | 178 | 388 | 3 | 1500 | 2000 | |

| 170 | 260 | 42 | 2.1 | 226 | 350 | QJ1034 | 176134 | 8.5 | 182 | 248 | 2 | 1700 | 2400 |

| 265 | 42 | 2.1 | 226 | 350 | QJF1034X1 | 176734X1 | 9 | 182 | 248 | 2 | 1300 | 1600 | |

| 310 | 52 | 4 | 358 | 480 | QJ234 | 176234 | 19.5 | 188 | 292 | 3 | 1600 | 2200 | |

| 360 | 72 | 4 | 618 | 965 | QJ334 | 176334 | 41.5 | 188 | 342 | 3 | 1400 | 1900 | |

| 180 | 280 | 46 | 2.1 | 335 | 408 | QJ1036 | 176136 | 11 | 192 | 268 | 2 | 1600 | 2200 |

| 320 | 52 | 4 | 392 | 545 | QJ236 | 176236 | 20.5 | 198 | 3020 | 3 | 1500 | 2000 | |

| 380 | 75 | 637 | 1020 | QJ336 | 47.5 | 198 | 362 | 3 | 1300 | 1800 | |||

| Boundary dimensions | Basic load ratings | Designations | Mass | Installation dimersion | Limiting speeds | ||||||||

| mm | kN | Current | Original | kg | mm | r/min | |||||||

| d | D | B | rmin | Cr | Cor | damin | Damax | ramax | Grease | Oil | |||

| 190 | 290 | 46 | 2.1 | 348 | 430 | QJ1038 | 179138 | 11.5 | 202 | 278 | 2 | 1600 | 2200 |

| 340 | 55 | 4 | 455 | 735 | QJ238 | 176238 | 39 | 208 | 322 | 3 | 1400 | 2200 | |

| 200 | 310 | 51 | 2.1 | 380 | 498 | QJ1040 | 176140 | 14.9 | 212 | 298 | 2 | 1500 | 2000 |

| 360 | 58 | 4 | 507 | 850 | QJ240 | 176240 | 27 | 218 | 342 | 3 | 1300 | 1800 | |

| 360 | 70 | 4 | 520 | 865 | QJF1240 | - | 32.5 | 218 | 342 | 3 | 1300 | 1800 | |

| 220 | 340 | 56 | 3 | 448 | 622 | QJ1044 | 176144 | 19.6 | 234 | 326 | 2.5 | 1300 | 1800 |

| 400 | 78 | 4 | 592 | 1020 | QJ1244 | 45.5 | 238 | 382 | 3 | 1100 | 1600 | ||

| 460 | 88 | 5 | 780 | 1400 | QJ344 | 78 | 242 | 438 | 4 | 1000 | 1500 | ||

| 240 | 360 | 56 | 3 | 458 | 655 | QJ1048 | 176148 | 21 | 254 | 346 | 2.5 | 1200 | 1700 |

| 440 | 85 | 4 | 663 | 1220 | QJ1248 | 61 | 258 | 422 | 3 | 1000 | 1500 | ||

| 260 | 360 | 46 | 2.1 | 390 | 710 | QJ1952 | 15 | 271 | 349 | 2 | 1100 | 1600 | |

| 400 | 65 | 4 | 510 | 765 | QJ1052 | 176152 | 31.3 | 278 | 382 | 3 | 1000 | 1500 | |

| 280 | 420 | 65 | 4 | 540 | 835 | QJ1056 | 176156 | 33.2 | 298 | 402 | 3 | 950 | 1400 |

| 500 | 90 | 5 | 728 | 1460 | QJ1256 | 82 | 302 | 478 | 4 | 950 | 1400 | ||

| 300 | 460 | 74 | 4 | 630 | 1040 | QJF1060 | 116160 | 47 | 318 | 442 | 3 | 900 | 1300 |

| 540 | 98 | 5 | 832 | 1760 | QJ1260 | 105 | 322 | 518 | 4 | 850 | 1200 | ||

| 320 | 480 | 74 | 4 | 650 | 1090 | QJ1064 | 176164 | 49.5 | 338 | 462 | 3 | 850 | 1200 |

| 580 | 105 | 5 | 923 | 2040 | QJ1264 | 130 | 342 | 558 | 4 | 800 | 1100 | ||

| 340 | 520 | 82 | 5 | 725 | 1270 | QJ1068 | 176168 | 67.5 | 362 | 498 | 4 | 800 | 1100 |

| 620 | 118 | 6 | 1060 | 2450 | QJ1268 | 165 | 368 | 592 | 5 | 750 | 1000 | ||

| 360 | 540 | 82 | 5 | 768 | 1380 | QJ1072 | 176172 | 69.2 | 382 | 518 | 4 | 800 | 1100 |

| 650 | 122 | 6 | 999 | 2340 | QJ 1272 | 1176272 | 190 | 388 | 622 | 5 | 700 | 950 | |

| Boundary dimensions | Basic load ratings | Designations | Mass | Installation dimersion | Limiting speeds | ||||||||

| mm | kN | Current | Original | kg | mm | r/min | |||||||

| d | D | B | rmin | Cr | Cor | damin | Damax | ramax | Grease | Oil | |||

| 380 | 560 | 82 | 5 | 737 | 1710 | QJ1076 | 176176 | 73.5 | 402 | 538 | 4 | 750 | 1000 |

| 680 | 132 | 6 | 1053 | 2565 | QJ1276 | 1176276 | 220 | 408 | 652 | 5 | 670 | 900 | |

| 400 | 600 | 90 | 5 | 814 | 1944 | QJ1080 | 176180 | 95.5 | 422 | 578 | 4 | 700 | 950 |

| 720 | 140 | 6 | 1170 | 2925 | QJ1280 | 1176280 | 265 | 428 | 692 | 5 | 600 | 800 | |

| 420 | 560 | 65 | 4 | 573 | 1440 | QJ1984 | 1176984 | 51 | 438 | 542 | 3 | 700 | 950 |

| 620 | 90 | 5 | 831 | 2052 | QJ1084 | 176184 | 99.5 | 442 | 598 | 4 | 670 | 900 | |

| 760 | 150 | 7.5 | 1287 | 3375 | QJ1284 | 1176284 | 315 | 456 | 724 | 6 | 560 | 750 | |

| 440 | 600 | 74 | 4 | 685 | 1710 | QJ1988 | 1176988 | 65 | 458 | 582 | 3 | 670 | 900 |

| 650 | 94 | 6 | 896 | 2250 | QJ1088 | 176188 | 115 | 468 | 622 | 5 | 630 | 850 | |

| 790 | 155 | 7.5 | 1260 | 3375 | QJ1288 | 1176288 | 350 | 476 | 754 | 6 | 560 | 750 | |

| 460 | 680 | 100 | 6 | 936 | 2385 | QJ1092 | 176192 | 130 | 488 | 652 | 5 | 600 | 800 |

| 830 | 165 | 7.5 | 1377 | 3825 | QJ1292 | 1176292 | 415 | 496 | 794 | 6 | 530 | 700 | |

| 480 | 700 | 100 | 6 | 954 | 2520 | QJ1096 | 176196 | 135 | 508 | 672 | 5 | 560 | 750 |

| 870 | 170 | 7.5 | 1512 | 4275 | QJ1296 | 1176296 | 470 | 516 | 834 | 6 | 500 | 670 | |

YOU MAY LIKE

VIEW MOREAngular Contact Ball Bearing

VIEW MOREAngular Contact Ball Bearing VIEW MOREAxial Deep Groove Ball Bearing

VIEW MOREAxial Deep Groove Ball Bearing VIEW MORERadial Thrust Ball Bearing

VIEW MORERadial Thrust Ball Bearing VIEW MOREAngular Contact Ball Bearings Single Row

VIEW MOREAngular Contact Ball Bearings Single Row VIEW MOREThrust Ball Bearing

VIEW MOREThrust Ball Bearing VIEW MORE4 Point Angular Contact Ball Bearing

VIEW MORE4 Point Angular Contact Ball Bearing VIEW MOREAngular Contact Ball Bearings

VIEW MOREAngular Contact Ball Bearings VIEW MORELarge Thrust Ball Bearing

VIEW MORELarge Thrust Ball Bearing