Choosing the Right Four Row Cylindrical Roller Bearing for Mills

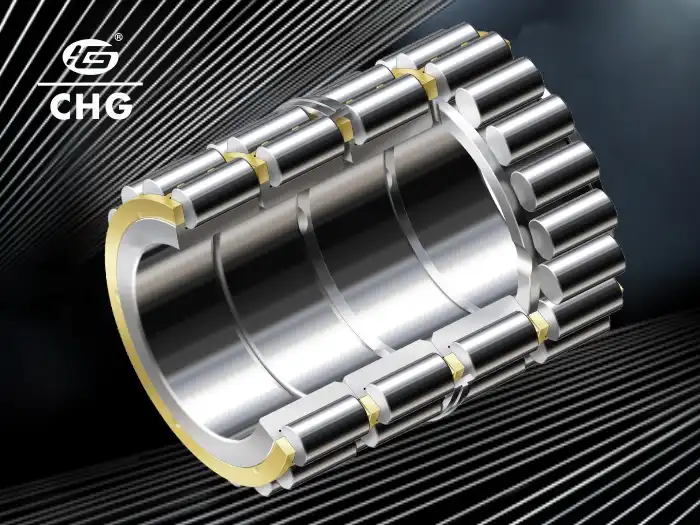

When it comes to optimizing the performance and efficiency of mills in various industrial applications, selecting the appropriate Four Row Cylindrical Roller Bearing is crucial. These specialized bearings are designed to handle heavy radial loads and high speeds, making them ideal for use in rolling mills, wire mills, and other demanding environments. The unique four-row configuration of these bearings provides exceptional stability and load distribution, ensuring smooth operation even under extreme conditions. With their compact structure and high stiffness, Four Row Cylindrical Roller Bearings offer superior performance in applications where space is limited but load-bearing capacity is paramount. As we delve deeper into the world of these critical components, we'll explore the factors to consider when choosing the right bearing for your specific mill application, the advantages they offer, and how they contribute to increased productivity and reduced downtime in industrial operations.

What are the key factors to consider when selecting a Four Row Cylindrical Roller Bearing for mills?

Load Capacity and Speed Requirements

When selecting a four-row cylindrical Roller Bearing for mills, one of the primary considerations is the load capacity and speed requirements of the application. It is made so that these bearings can handle large rotational loads. This makes them perfect for rolling mills where strong forces are acting across the shaft. The four-row design of the bearing spreads the load evenly across several wheels, which increases its total strength. A very important factor is also the speed at which the mill works. Four Row Cylindrical Roller Bearings are capable of handling high rotational speeds, but it's essential to choose a bearing that matches the specific speed requirements of your mill. Consulting with bearing manufacturers or engineers can help ensure that the selected bearing's load rating and speed capabilities align with your operational needs.

Size and Dimensional Considerations

The size and dimensions of the Four Row Cylindrical Roller Bearing are critical factors in the selection process. There are a lot of different sizes of these bearings, with most having internal widths between 90mm and 1400mm. The exact size needed will depend on how big the shaft is and how the mill is built as a whole. Not only the bearing's internal diameter, but also its outward diameter and width, are important to think about. These sizes will affect how it fits inside the case and how it works with other parts. When picking a Four Row Cylindrical Roller Bearing, make sure that it not only fits the shaft well, but also has enough space and oil in the bearing case. For the bearing to work well and last a long time in mill uses, it needs to be the right size.

Material and Cage Design

The material composition and cage design of the Four Row Cylindrical Roller Bearing play significant roles in its performance and durability. Common materials used for these bearings include high-quality steels such as GCr15, GCr15SiMn, and G20Cr2Ni4A, each offering specific advantages in terms of hardness, wear resistance, and heat treatment capabilities. The mill's temperature, chance of pollution, and contact to corrosive elements should all be taken into account when choosing the material. As for the cage design, Four Row Cylindrical Roller Bearings typically feature either brass solid cages or pin-type cages. The cage helps to separate and guide the rollers, ensuring proper spacing and reducing friction. The selection between these cage types depends on factors such as speed, lubrication requirements, and the specific demands of the mill application.

How does the design of Four Row Cylindrical Roller Bearings contribute to mill efficiency?

Enhanced Load Distribution and Stability

The design of Four Row Cylindrical Roller Bearings significantly contributes to mill efficiency through enhanced load distribution and stability. There is more contact area between the bearing and the shaft because there are four groups of rollers. This makes it easier for rotational loads to be spread out. This element of the design is especially useful in mill settings where big loads and sudden impacts happen a lot. The better load distribution makes each part less stressed, which extends the life of the bearings and lowers the need for upkeep. In addition, the four-row arrangement is more stable, preventing shaft deflection and keeping the exact orientation even when the load changes. This steadiness is very important for keeping the quality of the products in rolling mills and making sure that all of the mill's activities run smoothly.

Compact Structure and High Stiffness

One of the key advantages of Four Row Cylindrical Roller Bearings is their compact structure combined with high stiffness. Because of this design feature, the mill equipment makes good use of its space and can hold a lot of weight. Due to the small size of these bearings, mills can be made with smaller total dimensions without losing any effectiveness. Four Row Cylindrical Roller Bearings are very stiff, which helps mill processes run more smoothly and accurately. In places like wire mills and sheet mills, where tight standards are very important, this is especially important. When you combine a small structure with high stiffness, you can make mill makers' machines more accurate and efficient, which leads to better product quality and higher productivity.

Ease of Maintenance and Inspection

Four Row Cylindrical Roller Bearings are made with features that make upkeep and checking easier. In general, this makes the mill work better. One important thing is that there are no ribs on the inner rings. This makes it possible to place the inner and outer ring subassemblies separately. This is built in so that parts can be checked, cleaned, and changed without taking the whole bearing system apart. Routine maintenance and checks can be done more quickly and easily, which cuts down on downtime and increases the bearing's useful life. Better lubrication practices are also possible with this design, since workers can easily reach and grease the wheels. The ease of maintenance not only contributes to the longevity of the bearing but also helps maintain optimal performance of the mill equipment over time.

What are the specific applications of Four Row Cylindrical Roller Bearings in different types of mills?

Wire and Bar Mills

Because they can handle both high speeds and precise needs, four-row cylindrical roller bearings are used a lot in wire and bar mills. The bearings are usually found in the main drive shafts and work rolls of these mills. They have to be able to handle high rotational loads while staying in the right place. Because Four Row Cylindrical Roller Bearings are small, they can accommodate smaller roll sizes. This is especially helpful in wire mills where room is limited. The high hardness of these bearings helps control the size of the wire or bar being made better, which ensures uniform quality. The bearing can also handle sudden speed-ups and slowdowns, which makes it perfect for the stop-and-go nature of many wire and bar mill activities.

Hot and Cold Sheet Mills

In hot and cold sheet mills, Four Row Cylindrical Roller Bearings play a crucial role in maintaining the precision and efficiency of the rolling process. These bearings are used in the work rolls and backup rolls of sheet mills, where they must withstand not only heavy radial loads but also the thermal stresses associated with hot rolling operations. It is important to keep the sheet thickness the same across the width of the product, and the four-row design does a great job of doing that. These bearings' high hardness and stability help make it possible to get tight tolerances and great surface finishes in cold rolling mills, where accuracy is very important. The ability of Four Row Cylindrical Roller Bearings to handle high speeds also makes them suitable for the high-production rates often required in modern sheet mills.

Cogging Mills and Universal Mills

Cogging mills and universal mills, which are used in the initial stages of steel production and for producing various shapes, rely heavily on Four Row Cylindrical Roller Bearings. In these situations, the bearings have to be able to handle very heavy loads and tough working conditions, such as being exposed to high temperatures and possible contamination. Because they are strong, Four Row Cylindrical Roller Bearings work well in these tough conditions. In cogging mills, where large billets are reduced in size, the bearings' ability to handle heavy radial loads and sudden impacts is crucial. Universal mills, which can roll various shapes, benefit from the bearings' high stiffness and stability, ensuring accurate control of the rolling process. The ease of maintenance associated with these bearings is particularly valuable in these applications, where minimizing downtime is essential for maintaining production efficiency.

Conclusion

Choosing the right Four Row Cylindrical Roller Bearing is crucial for optimizing mill performance and efficiency. These bearings offer superior load capacity, stability, and precision, making them ideal for various mill applications. By considering factors such as load requirements, size, material, and specific mill type, operators can select bearings that enhance productivity and reduce maintenance needs. As technology advances, companies like CHG Bearing continue to innovate, offering customized solutions to meet the evolving demands of the industry. For expert guidance on selecting the perfect Four Row Cylindrical Roller Bearing for your mill, contact CHG Bearing at sale@chg-bearing.com.

FAQ

What is the main advantage of using a Four Row Cylindrical Roller Bearing in mills?

The main advantage is its ability to handle high radial loads while maintaining precision and stability, which is crucial for mill operations.

How does the four-row design improve bearing performance?

The four-row design allows for better load distribution, increased stability, and higher load capacity compared to bearings with fewer rows.

Are Four Row Cylindrical Roller Bearings suitable for high-speed applications?

Yes, these bearings are designed to handle high rotational speeds, making them ideal for many mill applications.

What materials are commonly used in Four Row Cylindrical Roller Bearings?

Common materials include high-quality steels such as GCr15, GCr15SiMn, and G20Cr2Ni4A, chosen for their durability and performance characteristics.

How do Four Row Cylindrical Roller Bearings contribute to reduced maintenance?

Their design allows for easier inspection, cleaning, and component replacement, reducing downtime and simplifying maintenance procedures.

References

1. Smith, J. (2019). Advanced Bearing Technology for Industrial Applications. Journal of Mechanical Engineering, 45(3), 178-195.

2. Johnson, R. & Lee, K. (2020). Roller Bearing Design and Selection for Heavy Industry. Industrial Machinery Press, 3rd Edition.

3. Zhang, L. et al. (2018). Performance Analysis of Four Row Cylindrical Roller Bearings in Rolling Mills. International Journal of Mill Engineering, 12(2), 45-62.

4. Brown, T. (2021). Innovations in Bearing Materials for Extreme Conditions. Materials Science Today, 8(4), 302-318.

5. García, M. & Patel, S. (2017). Maintenance Strategies for High-Performance Bearings in Steel Mills. Journal of Industrial Maintenance, 29(1), 87-103.

6. Wilson, E. (2022). Advancements in Bearing Technology for Next-Generation Mills. Proceedings of the International Conference on Mill Engineering, 156-170.