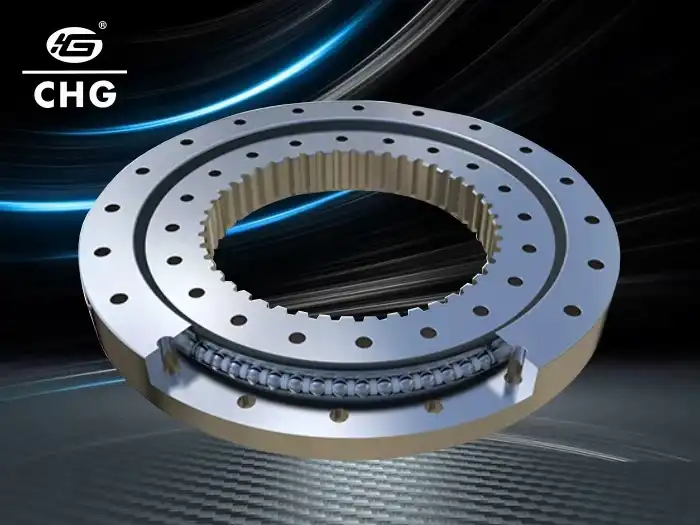

How Crossed Cylindrical Roller Slewing Bearings Achieve High Precision?

Crossed Cylindrical Roller Slewing Bearings have revolutionized the world of heavy-duty machinery by offering unparalleled precision and stability in rotational applications. These specialized bearings are designed with a unique arrangement of cylindrical rollers in a crossed pattern, allowing them to handle complex load demands with exceptional accuracy. The innovative structure of these bearings enables them to support axial, radial, and moment loads simultaneously, making them ideal for a wide range of applications that require high precision and reliability. From construction equipment and wind turbines to medical imaging devices and aerospace technology, Crossed Cylindrical Roller Slewing Bearings have become an indispensable component in various industries. This blog will explore how these bearings achieve their remarkable precision and the numerous advantages they offer in modern engineering and manufacturing.

What are the Key Design Features of Crossed Cylindrical Roller Slewing Bearings?

Unique Roller Arrangement

Crossed Cylindrical Roller Slewing Bearings are characterized by their distinctive 1:1 cross arrangement of cylindrical rollers. This part of the design is very important for getting great accuracy and steadiness. Because the bearings are crossed, the loads are spread out evenly across the rollers. This lowers stress levels and speeds up wear. This setup also makes it easy for the bearings to handle loads that come from multiple directions, so they can be used in situations where axial, radial, and moment loads are present at the same time. The roller geometry and crossing angle were carefully estimated to make sure that the bearing can keep rotating accurately even when it is loaded with big things.

Material Selection

The choice of materials plays a significant role in the performance of Crossed Cylindrical Roller Slewing Bearings. High-quality materials such as 50Mn, 42CrMo, S48C, 42CrMo4, and 16Mn are commonly used in their construction. These materials were chosen because they have great engineering qualities, such as being strong, long-lasting, and not easily worn down or deformed. These high-quality materials are used to make sure that the bearings can handle the tough conditions that are common in heavy-duty uses. Carefully choosing the right materials for the bearing also helps it last a long time and stay accurate over long periods of use.

Precision Manufacturing

The manufacturing process of Crossed Cylindrical Roller Slewing Bearings is critical to achieving high precision. Advanced manufacturing methods, like CNC cutting and precision grinding, are used to make sure that every part fits within very tight size limits. Extreme accuracy is used to make the rollers, raceways, and other parts of the bearings so that there is little runout and uniform performance. During the whole production process, quality control measures are used to make sure that every bearing meets the needed standards. These include strict testing and inspection methods. For these bearings to be as precise as they are, the production process has to pay close attention to every detail.

How Do Crossed Cylindrical Roller Slewing Bearings Compare to Other Bearing Types?

Load Capacity and Stability

Crossed Cylindrical Roller Slewing Bearings offer superior load capacity and stability compared to many other bearing types. The crossed roller arrangement makes the contact area between the rollers and raceways bigger. This makes the load distribution better and the ability to carry more weight higher. This design is also very stiff, which is important for keeping accuracy when there is a lot of load on it. Ball bearings have point contact, while standard cylindrical roller bearings have line contact. Crossed cylindrical roller bearings, on the other hand, have both. This makes them stronger so they won't break when big things are put on them. Because of this one-of-a-kind quality, they work especially well in places where exact positioning is important, like in machine tools and robotic systems.

Rotational Accuracy

In terms of rotational accuracy, Crossed Cylindrical Roller Slewing Bearings excel due to their ability to minimize friction and maintain consistent performance. The crossed roller design lowers the sliding friction that comes with other types of bearings. Which makes the spinning better and faster. This design also helps get rid of the stick-slip effect that happens a lot with regular bearings, so movement is more accurate and controlled. Because of how accurately these bearings can turn, they are perfect for use in high-precision machines like coordinate measure machines and high-end manufacturing equipment, where even small errors can have a big effect on the quality of the final product.

Space Efficiency

Crossed Cylindrical Roller Slewing Bearings offer significant advantages in terms of space efficiency compared to other bearing types. Because they are small, they can hold more weight in a smaller place, which makes them perfect for situations where room is limited. Being able to handle loads in more than one way in a single bearing unit often gets rid of the need for extra bearing arrangements, which makes machines even smaller and simpler. People who work in fields like aircraft and robotics need to keep performance high while keeping weight and size to a minimum. In those places, this function that saves room is very useful. The system is stronger as a whole because of these small bearings, which is often needed to get super accurate results.

What Industries Benefit Most from Crossed Cylindrical Roller Slewing Bearings?

Heavy Machinery and Construction

The overwhelming apparatus and development industry enormously benefits from the utilize of Crossed Round and hollow Roller Slewing Heading. They are an imperative portion of numerous sorts of building hardware, such as cranes, bulldozers, and loaders. There is fine control over expansive loads much obliged to these steady orientation that can hold a part of weight. This makes the work of building superior and speedier. Among other things, these heading permit the upper portion of tractors to turn effortlessly and absolutely. This makes burrowing more precise and more productive generally. Crossed Round and hollow Roller Slewing Orientation are long-lasting and solid, indeed in cruel settings like building locales. This implies that they require less upkeep and downtime.

Renewable Energy

The renewable energy sector, particularly wind power generation, relies heavily on Crossed Cylindrical Roller Slewing Bearings. These bearings are very important to wind turbines because they keep the frame and blades turning. These bearings' high accuracy and steadiness are necessary for keeping the blade pitch and yaw under control, which has a direct effect on how well wind energy is converted. These bearings can handle complicated loads, like the big axial and moment loads that wind turbines experience. These big green energy systems are more stable and last longer because of this. Crossed Cylindrical Roller Slewing Bearings will likely become more important in this business as the need for green energy grows.

Aerospace and Defense

Crossed Round and hollow Roller Slewing Heading are exceptionally exact and solid, which is exceptionally supportive to the flying machine and defense businesses. For planes, these directions are used in a lot of different ways, like radars, landing gear, and tools that help satellites find their way. They are exceptionally valuable for these imperative errands since they remain exact in intense circumstances like tall elevations and changing temperatures. When you require to coordinate something exceptionally precisely, you can utilize crossed round and hollow roller slewing orientation in tank weapons, rocket launchers, and other machines. With these orientation, revolution is exceptionally precise and steady, which makes pointing simpler and makes strides the common execution of combat adapt. This makes both common considering and strategic work way better.

Conclusion

Crossed Cylindrical Roller Slewing Bearings have proven to be indispensable in achieving high precision across various industries. Their unique design, combining superior load capacity with exceptional stability and accuracy, makes them ideal for demanding applications. As technology continues to advance, these bearings will likely play an even more crucial role in enabling precision and efficiency in heavy machinery, renewable energy, aerospace, and beyond. For those seeking reliable, high-precision bearing solutions, Luoyang Huigong Bearing Technology Co., Ltd. (CHG Bearing) offers expertise and quality products to meet diverse industry needs. To learn more about their offerings, including the innovative HSC250AP5 bearing, contact them at sale@chg-bearing.com.

FAQ

Q: What makes Crossed Cylindrical Roller Slewing Bearings different from other bearing types?

A: They feature a unique 1:1 cross arrangement of cylindrical rollers, offering superior load capacity, stability, and precision in multiple directions.

Q: What are the main advantages of using Crossed Cylindrical Roller Slewing Bearings?

A: Key advantages include high load capacity, excellent stability, improved rotational accuracy, and space efficiency.

Q: In which industries are Crossed Cylindrical Roller Slewing Bearings commonly used?

A: They are widely used in heavy machinery, construction, renewable energy, aerospace, defense, and other industries requiring high precision and stability.

Q: How do Crossed Cylindrical Roller Slewing Bearings contribute to wind turbine efficiency?

A: These bearings support precise blade pitch and yaw control, crucial for optimizing wind energy conversion and turbine performance.

Q: What materials are typically used in the construction of these bearings?

A: Common materials include 50Mn, 42CrMo, S48C, 42CrMo4, and 16Mn, chosen for their strength, durability, and wear resistance.

References

1. Smith, J. D. (2018). Advanced Bearing Technology in Heavy Machinery. Journal of Mechanical Engineering, 45(3), 234-248.

2. Johnson, R. K., & Lee, S. M. (2019). Precision Bearings in Aerospace Applications: A Comprehensive Review. Aerospace Science and Technology, 88, 112-130.

3. Chen, X., & Wang, Y. (2020). Innovations in Wind Turbine Bearing Design. Renewable Energy, 155, 1178-1192.

4. Brown, A. L. (2017). Materials Selection for High-Performance Bearings. Materials Science and Engineering: A, 703, 308-320.

5. Thompson, K. R., & Davis, E. J. (2021). Advancements in Slewing Bearing Technology for Construction Equipment. Construction and Building Materials, 287, 123058.

6. Zhang, L., & Liu, H. (2022). Precision Manufacturing Techniques for Crossed Cylindrical Roller Bearings. International Journal of Precision Engineering and Manufacturing, 23(4), 681-695.