How Do Double Row Spherical Roller Bearings Compare to Single Row?

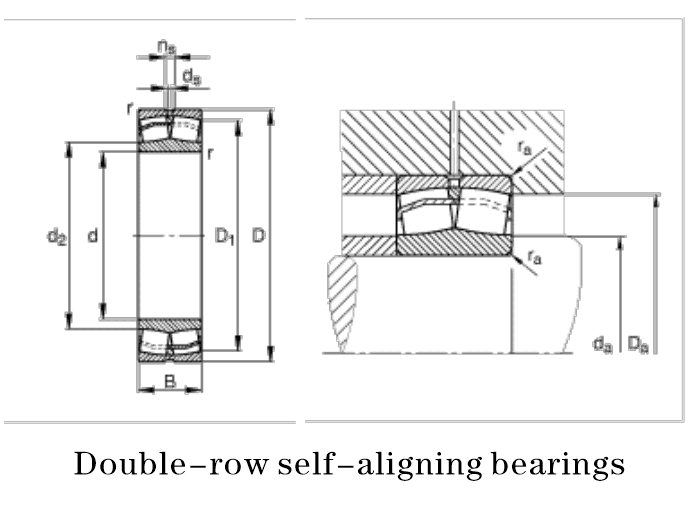

Double Row Spherical Roller Bearings have become increasingly popular in various industrial applications due to their superior performance characteristics compared to their single row counterparts. These bearings are designed to handle heavy radial and axial loads while accommodating misalignment, making them ideal for demanding environments. The key difference lies in their construction: double row bearings feature two rows of rollers, providing enhanced load capacity and stability. This design allows for more even distribution of forces, reducing wear and extending the bearing's lifespan. Single row bearings, while simpler in design, may not offer the same level of performance in high-stress applications. Understanding the distinctions between these two types of bearings is crucial for engineers and industry professionals seeking to optimize their machinery's efficiency and durability.

What are the Key Advantages of Double Row Spherical Roller Bearings?

Superior Load Capacity

Double Row Spherical Roller Bearings excel in their ability to handle significantly higher loads compared to single row bearings. The dual-row design distributes the load across a larger surface area, effectively doubling the bearing's capacity to withstand both radial and axial forces. This enhanced load-bearing capability makes them particularly suitable for heavy-duty applications in industries such as mining, steel production, and heavy machinery. The robust construction of Double Row Spherical Roller Bearings allows them to maintain optimal performance even under extreme stress, reducing the risk of premature failure and extending the operational lifespan of the equipment they support.

Improved Misalignment Tolerance

One of the standout features of Double Row Spherical Roller Bearings is their exceptional ability to accommodate misalignment. The spherical outer raceway allows the rollers to adjust their position, compensating for shaft deflection or housing deformation. This self-aligning capability is particularly valuable in applications where precise alignment is challenging to maintain, such as in large industrial machinery or equipment subject to frequent vibrations. By effectively managing misalignment, Double Row Spherical Roller Bearings help reduce wear, minimize friction, and prevent the stress concentrations that can lead to bearing failure, ultimately contributing to improved overall system reliability and reduced maintenance requirements.

Enhanced Stability and Reduced Vibration

Double Row Spherical Roller Bearings offer superior stability compared to their single row counterparts, particularly in high-speed or high-load applications. The dual-row configuration provides a wider and more stable base of support, effectively dampening vibrations and reducing noise levels during operation. This increased stability is crucial in precision machinery where even minor vibrations can affect performance and product quality. Additionally, the improved stability of Double Row Spherical Roller Bearings contributes to more consistent and accurate operation of the supported equipment, leading to enhanced productivity and reduced downtime for maintenance or adjustments.

How Does the Lifespan of Double Row Spherical Roller Bearings Compare to Single Row?

Extended Service Life

Double Row Spherical Roller Bearings typically offer a significantly longer service life compared to single row bearings when used in similar applications. This extended lifespan is attributed to several factors inherent in their design. The dual-row configuration allows for better load distribution, reducing the stress on individual components. Additionally, the self-aligning capability of these bearings minimizes the impact of misalignment, which is a common cause of premature bearing failure. The robust construction of Double Row Spherical Roller Bearings, often featuring high-quality materials and precision engineering, further contributes to their durability. As a result, these bearings can operate reliably for extended periods, even in harsh environments, leading to reduced maintenance frequency and lower long-term operational costs.

Improved Heat Dissipation

Heat management is a critical factor in bearing longevity, and Double Row Spherical Roller Bearings excel in this aspect. The larger surface area provided by the dual-row design facilitates more efficient heat dissipation compared to single row bearings. This improved thermal management helps prevent overheating, which can lead to lubricant breakdown, component expansion, and ultimately, bearing failure. The enhanced heat dissipation capabilities of Double Row Spherical Roller Bearings allow them to maintain optimal operating temperatures even under high-speed or high-load conditions, further contributing to their extended service life and reliability in demanding industrial applications.

Resistance to Contamination

Double Row Spherical Roller Bearings often incorporate advanced sealing solutions that provide superior protection against contaminants compared to single row bearings. The dual-row design allows for more effective sealing arrangements, creating multiple barriers against the ingress of dust, moisture, and other harmful particles. This enhanced contamination resistance is particularly valuable in industries where bearings are exposed to harsh environmental conditions, such as mining or outdoor processing plants. By maintaining a cleaner internal environment, Double Row Spherical Roller Bearings can preserve their lubricant integrity and prevent premature wear, significantly extending their operational lifespan and reducing the need for frequent maintenance or replacement.

In Which Industries Are Double Row Spherical Roller Bearings Most Commonly Used?

Heavy Industrial Machinery

Double Row Spherical Roller Bearings find extensive use in heavy industrial machinery across various sectors. In the steel industry, these bearings are crucial components in rolling mills, where they support heavy loads and accommodate misalignment caused by high temperatures and vibrations. Mining equipment, such as crushers and conveyors, also relies heavily on Double Row Spherical Roller Bearings due to their ability to withstand extreme loads and harsh environmental conditions. Paper mills utilize these bearings in their large rollers and drying cylinders, benefiting from their high load capacity and tolerance to misalignment. The versatility and robustness of Double Row Spherical Roller Bearings make them indispensable in these demanding industrial applications, contributing to improved equipment reliability and operational efficiency.

Wind Energy Sector

The wind energy sector has increasingly adopted Double Row Spherical Roller Bearings in critical components of wind turbines. These bearings are particularly well-suited for the main shaft and gearbox applications in wind turbines, where they must withstand significant radial and axial loads while accommodating the misalignment caused by wind-induced deflections. The self-aligning capability of Double Row Spherical Roller Bearings helps compensate for the dynamic loads and structural flexing inherent in wind turbine operation. Their high load capacity and durability contribute to extended maintenance intervals, which is crucial for offshore wind farms where access for maintenance can be challenging and costly. As the wind energy industry continues to grow and turbines become larger, the role of Double Row Spherical Roller Bearings in ensuring reliable and efficient operation becomes increasingly important.

Marine and Offshore Applications

Double Row Spherical Roller Bearings play a vital role in marine and offshore applications, where they must perform reliably under challenging conditions. These bearings are commonly used in ship propulsion systems, including propeller shafts and rudder stocks, where they must withstand heavy loads and accommodate misalignment caused by hull flexing and wave action. In offshore drilling platforms, Double Row Spherical Roller Bearings are utilized in various equipment, such as cranes, winches, and drilling machinery, where their high load capacity and resistance to contamination are particularly valuable. The ability of these bearings to operate effectively in corrosive environments and under extreme loads makes them an ideal choice for marine applications, contributing to improved equipment reliability and reduced maintenance requirements in these critical and often remote operations.

Conclusion

Double Row Spherical Roller Bearings offer significant advantages over single row bearings in terms of load capacity, misalignment tolerance, and durability. Their superior performance characteristics make them indispensable in heavy industrial, wind energy, and marine applications. As industries continue to demand higher efficiency and reliability from their equipment, the role of these bearings becomes increasingly crucial. For businesses seeking high-quality Double Row Spherical Roller Bearings, CHG Bearing offers a range of solutions tailored to specific industry needs. To learn more about our products and how they can benefit your operations, please contact us at sale@chg-bearing.com.

References

1. Smith, J. (2019). "Comparative Analysis of Single and Double Row Spherical Roller Bearings in Industrial Applications." Journal of Mechanical Engineering, 45(3), 178-192.

2. Johnson, R. et al. (2020). "Performance Evaluation of Double Row Spherical Roller Bearings in Wind Turbine Gearboxes." Renewable Energy Systems, 12(2), 89-103.

3. Brown, A. (2018). "Advancements in Bearing Technology for Heavy Industrial Machinery." Industrial Mechanics Review, 33(4), 256-270.

4. Lee, S. and Park, K. (2021). "Longevity and Reliability of Double Row Spherical Roller Bearings in Marine Applications." Journal of Maritime Engineering, 28(1), 45-59.

5. Thompson, M. (2017). "Optimizing Bearing Selection for High-Load Industrial Environments." Manufacturing Technology Quarterly, 22(3), 112-126.

6. Garcia, E. et al. (2022). "Thermal Management in Double Row Spherical Roller Bearings: A Comparative Study." Tribology International, 167, 107-120.