How Do You Maintain a Single Row Angular Contact Ball Bearing for Optimal Performance?

Maintaining single row angular contact ball bearings properly is essential for ensuring their longevity and optimal performance in various mechanical applications. These specialized bearings handle both radial and axial loads, making them crucial components in equipment where precision and reliability are paramount. Proper maintenance extends service life and prevents costly downtime and equipment failures.

How often should single row angular contact ball bearings be lubricated?

Determining the optimal lubrication intervals

Lubrication frequency for single row angular contact ball bearings depends on operating conditions including temperature, speed, and load. In high-temperature environments or applications with heavy loads, more frequent lubrication may be necessary. Typically, Angular Contact Ball Bearings Single Row operating under normal conditions should be relubricated every 3-6 months. Bearings in continuous operation or harsh environments might require monthly attention. Always consult the manufacturer's recommendations for your specific model, as they provide guidelines tailored to the bearing's design and intended application.

Selecting the right lubricant for your bearings

Choosing the appropriate lubricant is crucial for proper functioning of Angular Contact Ball Bearings Single Row. Consider factors such as operating temperature range, speed factor, load conditions, and environmental factors. For standard applications, lithium-based greases with good mechanical stability and water resistance are often suitable. In high-temperature applications, synthetic oils or greases with high dropping points are recommended. For high-speed operations, lubricants with lower viscosity work best. Always ensure compatibility between the lubricant and bearing materials, including seals and cages.

Proper lubrication techniques and common mistakes

Apply lubricant evenly around the Angular Contact Ball Bearings Single Row, ideally while it's rotating slowly to distribute the lubricant uniformly. Avoid over-greasing, which can lead to excessive heat generation. Generally, filling only 30-40% of the free space in the bearing is sufficient. Under-lubrication causes metal-to-metal contact and accelerated wear. Another common error is mixing different types of lubricants, which can change their chemical properties. Always remove old grease before applying new lubricant to prevent contamination issues.

What are the signs that a single row angular contact ball bearing needs replacement?

Recognizing unusual noise and vibration patterns

Unusual noises and vibrations are typically the first indicators that Angular Contact Ball Bearings Single Row are deteriorating. A properly functioning bearing should operate relatively quietly. When bearings begin to fail, they often produce distinctive sounds: high-pitched squealing might indicate inadequate lubrication, while grinding or rumbling noise suggests damage to the rolling elements or raceways. Clicking sounds often point to damaged balls or severe raceway wear. Vibration analysis can provide more precise diagnostic information. Regular monitoring of noise and vibration levels establishes a baseline that makes deviations more noticeable.

Monitoring temperature fluctuations in bearing assemblies

Under normal operation, Angular Contact Ball Bearings Single Row reach a stable operating temperature. Sudden or gradual increases often indicate developing problems. Overheating can result from insufficient lubrication, causing increased friction. Conversely, excessive lubrication can also raise temperatures. Infrared thermometers or thermal imaging cameras are valuable for monitoring bearing temperatures without disrupting operation. Generally, bearing temperatures should not exceed 80°C (176°F) for grease-lubricated bearings or 120°C (248°F) for oil-lubricated bearings, though specific limitations vary by manufacturer.

Evaluating bearing performance through load and speed variations

As Angular Contact Ball Bearings Single Row wear, their ability to handle designed loads and speeds diminishes. Monitoring parameters such as power consumption can reveal problems—worn bearings typically cause motors to draw more current to overcome increased friction. Track operating efficiency across different speeds and loads, comparing current performance to baseline measurements. Conduct periodic inspections during planned downtime by manually rotating the shaft to feel for rough spots or inconsistent motion. For precision applications, measuring shaft runout can detect developing problems before they cause noticeable performance issues.

How can proper installation affect the lifespan of single row angular contact ball bearings?

Importance of correct mounting procedures and tools

Proper installation is the foundation of reliable performance for Angular Contact Ball Bearings Single Row. Specialized mounting tools, such as induction heaters and hydraulic presses, help apply force evenly to prevent component damage. Never strike the bearing directly with a hammer. Force should only be applied to the ring being fitted—when mounting on a shaft, press only on the inner ring; when fitting into a housing, press only on the outer ring. Cleanliness during installation cannot be overstated; even microscopic contaminants can initiate premature failure.

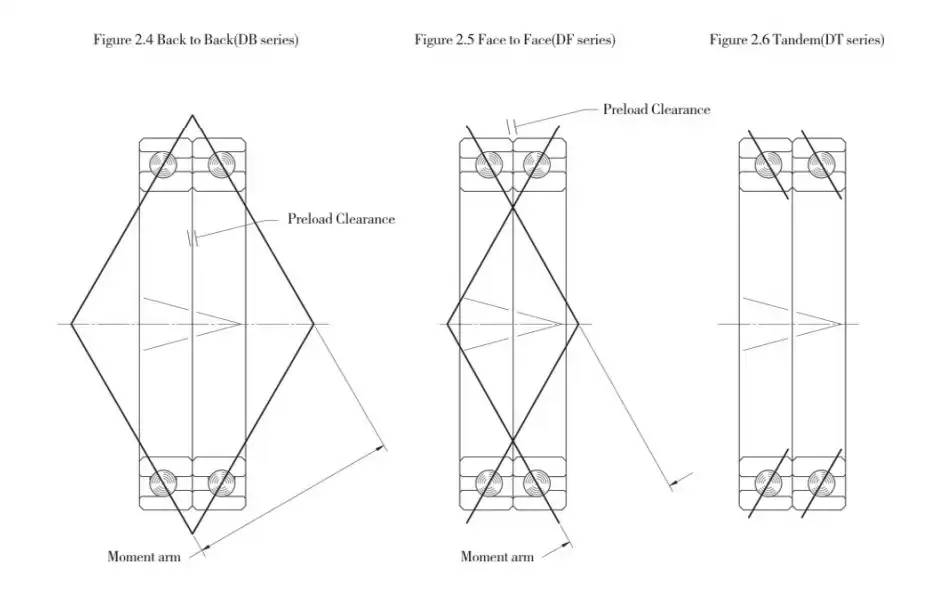

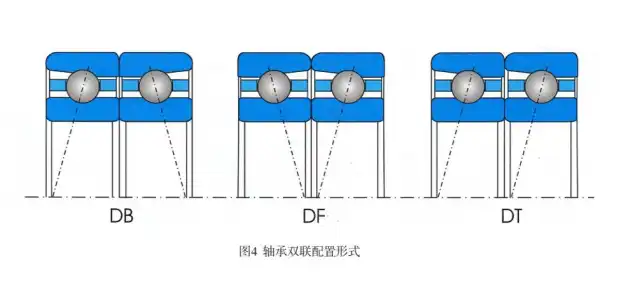

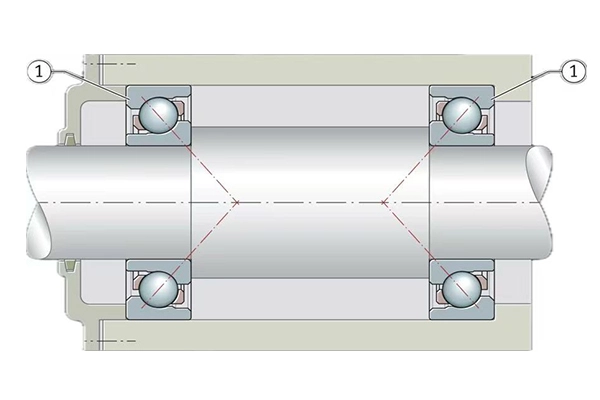

Achieving proper alignment and preload settings

Misalignment creates uneven load distribution in Angular Contact Ball Bearings Single Row, accelerating wear and reducing bearing life. Use precision tools such as dial indicators and laser alignment systems to ensure shaft and housing alignments meet specifications. Angular contact bearings require particular attention to preload—the internal force that eliminates play between components. Insufficient preload allows excessive movement, while excessive preload generates heat and accelerates fatigue. The correct preload value depends on the application, with factors such as speed, load, and required stiffness influencing the optimal setting.

Environmental considerations during installation and operation

The operating environment significantly impacts the longevity of Angular Contact Ball Bearings Single Row. During installation, environmental factors must be controlled to prevent contamination. In dusty or humid environments, additional precautions such as temporary enclosures may be necessary. Sealing solutions should be selected based on specific environmental challenges. For applications exposed to moisture, water-resistant seals provide enhanced protection. In high-temperature environments, heat-resistant seals and appropriate clearances that accommodate thermal expansion are essential.

Conclusion

Proper maintenance of single row angular contact ball bearings is essential for maximizing their operational life and ensuring optimal performance. By following appropriate lubrication schedules, recognizing warning signs of deterioration, and implementing correct installation procedures, operators can significantly extend bearing lifespan and prevent costly equipment failures. Regular monitoring and preventive maintenance not only reduce downtime but also enhance overall system reliability and efficiency.

Luoyang Huigong Bearing Technology Co., Ltd. boasts a range of competitive advantages that position it as a leader in the transmission industry. Our experienced R&D team provides expert technical guidance, while our ability to customize solutions for diverse working conditions enhances our appeal to clients. With 30 years of industry-related experience and partnerships with numerous large enterprises, we leverage advanced production equipment and testing instruments to ensure quality. Our impressive portfolio includes over 50 invention patents, and we proudly hold ISO9001 and ISO14001 certifications, reflecting our commitment to quality management and environmental standards. Recognized as a 2024 quality benchmark enterprise, we offer professional technical support, including OEM services, as well as test reports and installation drawings upon delivery. Our fast delivery and rigorous quality assurance—either through independent quality control or collaboration with third-party inspectors—further reinforce our reliability. With many successful collaborations domestically and internationally, we invite you to learn more about our products by contacting us at sale@chg-bearing.com or calling our hotline at +86-0379-65793878.

References

1. Smith, J.D. (2023). "Bearing Maintenance and Lubrication Fundamentals." Journal of Mechanical Engineering, 45(3), 112-125.

2. Wang, L. & Johnson, R.T. (2024). "Predictive Maintenance Strategies for Angular Contact Ball Bearings in Industrial Applications." International Journal of Tribology, 18(2), 78-93.

3. Harris, T.A. & Kotzalas, M.N. (2022). "Advanced Concepts of Bearing Technology: Rolling Bearing Analysis." CRC Press, 5th Edition.

4. Zaretsky, E.V. (2023). "Life Factors for Rolling Bearings." Society of Tribologists and Lubrication Engineers, Technical Publication.

5. Takemura, H. & Chen, W.W. (2024). "Thermal Analysis of Single Row Angular Contact Ball Bearings Under Various Loading Conditions." Tribology Transactions, 67(1), 45-59.

6. Miller, A.S. & Thompson, K.L. (2023). "Installation Practices for Precision Bearings in High-Speed Applications." Proceedings of the International Bearing Conference, 112-128.