How Does a Tower Crane Slewing Bearing Function?

Tower crane slewing bearings are crucial components that enable the smooth and efficient rotation of tower cranes, playing a pivotal role in construction and industrial operations. These specialized bearings are designed to support massive loads while facilitating precise movements, allowing tower cranes to lift and position heavy materials with remarkable accuracy. The functionality of a tower crane slewing bearing is rooted in its ability to handle both axial and radial loads simultaneously, as well as withstand significant overturning moments. This unique design allows the crane's upper structure to rotate seamlessly atop the stationary lower section, enabling operators to maneuver loads across construction sites with ease. The bearing's structure typically includes a large ring with raceways for rolling elements, often incorporating gears for powered rotation. By reducing friction between the rotating and stationary parts of the crane, these bearings ensure smooth operation, increased efficiency, and extended equipment lifespan, making them indispensable in modern construction and industrial applications.

What are the Key Components of a Tower Crane Slewing Bearing?

Races and Rolling Elements

The races and rolling elements are fundamental components of a tower crane slewing bearing. The races, typically made of high-grade steel, form the inner and outer rings of the bearing. The rollers, which can be balls, cylindrical rollers, or curved rollers, move along raceways that have been carefully cut into these rings. The type of rolling part used relies on the tower crane's load needs and how it is used. For example, ball bearings allow for smooth movement and can handle both horizontal and axial loads. Roller bearings, on the other hand, can handle more weight and are stiffer. The efficiency, load-bearing ability, and life of the bearing are all directly affected by the quality and arrangement of these parts. When used in tower cranes, the moving parts must be able to handle heavy loads and harsh conditions while still running smoothly.

Sealing System

The sealing system is an important part of tower crane slewing bearings because it keeps the grease in and keeps the internal parts clean. Because tower cranes are out in the open, these bearings can be damaged by dust, water, and other natural toxins that can shorten their life and make them less effective. These contaminants can't get through good seals, which are usually made of synthetic rubber or polymer materials. There may be more than one layer in the sealing system, such as primary seals, secondary seals, and maze seals. Each layer protects in its own way. Some high-tech tower crane slewing bearings also have grease tanks and distribution lines built in as part of the sealing system. This makes sure that the bearings are always lubricated and protects them even more from contaminants. The sealing system's efficiency is very important for keeping the bearings in good shape and making sure the crane works reliably in all kinds of weather.

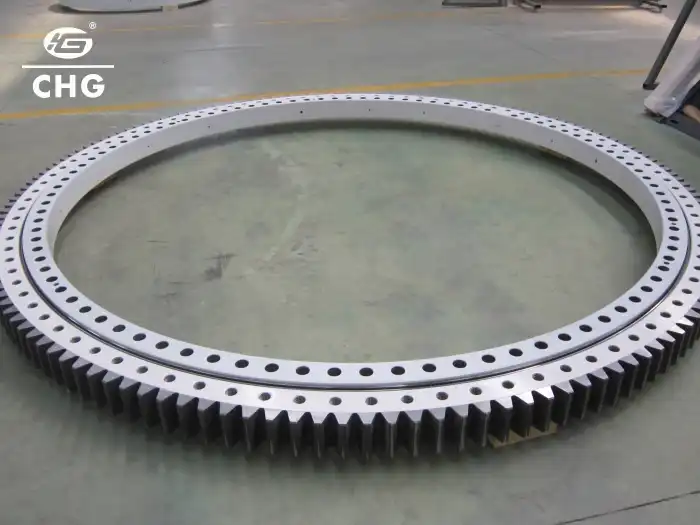

Gear System

Many tower crane slewing bearings incorporate a gear system, which is essential for powered rotation of the crane's upper structure. The gear system typically consists of an internal or external gear ring integrated into the bearing structure. This gear meshes with a pinion gear connected to the crane's slewing motor, enabling controlled rotation. The precision of the gear teeth and their engagement is crucial for smooth and accurate movements. In tower crane applications, the gear system must be robust enough to handle high torque loads and resist wear over extended periods of operation. Some advanced slewing bearings feature hardened gear teeth or special coatings to enhance durability and reduce friction. The gear system's design also considers factors like backlash reduction and load distribution to ensure precise control and longevity of the tower crane slewing bearing.

How Does the Load Distribution Mechanism Work in Tower Crane Slewing Bearings?

Axial Load Handling

The axial load handling capability of tower crane slewing bearings is a critical aspect of their design and function. These bearings are designed to handle huge loads that are pushed up and down, which is common in tower crane work. The vertical load is mostly spread out over the raceway surfaces and rolling parts. Many tower crane slewing bearings use a four-point contact design to make this happen. This means that the moving elements, which are usually balls, touch the raceways in four different places. This arrangement makes it possible for axial forces to be spread out in the best way possible, avoiding stress buildsups in one area that could cause early failure or wear. The geometry of the raceways and the precision of the rolling elements are carefully calculated to ensure even load distribution across the entire bearing. Additionally, some advanced tower crane slewing bearings incorporate tapered roller elements, which are particularly effective at handling heavy axial loads due to their larger contact area with the raceways.

Radial Load Management

Radial load management is another crucial function of tower crane slewing bearings. These bearings must withstand significant horizontal forces resulting from the crane's lifting operations and environmental factors like wind. The radial load is primarily managed through the arrangement and design of the rolling elements and raceways. In bearings using cylindrical or tapered rollers, the rollers are oriented to efficiently handle radial loads, distributing the force evenly across their length. For ball-type slewing bearings, the curvature of the raceways and the size of the balls are optimized to handle radial loads effectively. Some tower crane slewing bearings employ a crossed roller design, where the rollers are arranged at right angles to each other, enhancing the bearing's ability to handle combined radial and axial loads. This arrangement also makes the bearing stiffer overall, which is important for keeping the crane stable while it's working.

Moment Load Distribution

Moment load distribution is a critical function of tower crane slewing bearings, as these components must resist the overturning forces generated during crane operations. The moment load, or tilting moment, is caused by the eccentric loading of the crane arm and the payload. Tower crane slewing bearings are designed with a large diameter to effectively counteract these moment loads. The distribution of moment loads is achieved through the strategic placement of rolling elements and the design of the raceway profiles. In many cases, the bearing uses a combination of axial and radial load-bearing surfaces to create a couple that resists the overturning moment. Some advanced slewing bearings feature asymmetric raceway designs or variable roller sizes to optimize moment load distribution. The mounting arrangement of the bearing, including the number and placement of mounting bolts, is also very important for moving moment loads from the bearing to the crane frame. This keeps the whole thing stable and safe while it's in use.

What Are the Maintenance Requirements for Tower Crane Slewing Bearings?

Lubrication Protocols

Proper lubrication is paramount for the optimal performance and longevity of tower crane slewing bearings. To keep these bearings from rusting, reducing friction, and stopping wear, they need to be oiled on a frequent basis. The process for greasing usually includes using high-quality grease that is made for heavy-duty uses. How often and how much to grease depends on things like the size of the bearing, how it is used, and what the maker recommends. For easy upkeep, many tower crane slewing bearings come with grease nipples or automatic greasing systems. It's very important not to grease too much, because that can cause working temperatures to rise and seal damage. Maintenance crews should re-grease on a strict plan and keep an eye on the grease's state, looking for signs of contamination or wear. Some more modern tower crane slewing bearings have long-life lubrication systems or features that make them self-lubricating. This can make them more reliable overall and increase the time between maintenance visits.

Regular Inspection Procedures

Regular inspection procedures are essential for ensuring the continued safe and efficient operation of tower crane slewing bearings. These inspections should be conducted at predetermined intervals and include both visual and operational checks. During a visual check, the bearing is looked at for signs of damage, wear, or corrosion. The seals, mounting bolts, and easily available parts of the raceway are given the most attention. As part of operational checks, strange noises, movements, or changes in the way something rotates are checked for. Maintenance workers should also keep an eye on the bearing's preload and clearance, since changes in these areas can show signs of wear or possible problems. Advanced checking methods may include using special tools like endoscopes to look inside something or thermal imaging cameras to find hot spots that could mean there are problems with greasing or too much friction. Regularly checking the spinning torque can also tell you a lot about the state of the bearing. It's very important that these checks are done by trained professionals who can correctly read the results and suggest what should be done.

Wear and Tear Management

Managing wear and tear is crucial for maximizing the lifespan and maintaining the performance of tower crane slewing bearings. Preventative steps and response activities are both used in this process. To find early signs of wear, it's important to check the bearing clearance and raceway state on a regular basis. Once wear is found, it's important to figure out how bad it is and how it might affect the bearing's function. Small amounts of wear can be fixed by changing how the machine is oiled or how it is used, but bigger amounts of wear might need to be replaced. It's sometimes possible to fix up old slewing bearings, which can save you money compared to buying new ones. During this step, the raceways may need to be reground, rolling elements may need to be replaced, or seals may need to be improved. Using the right load management techniques, like not changing loads quickly or overdoing, can cut wear rates by a large amount. Protecting the bearing from dust and wetness in the surroundings by sealing it well and cleaning it regularly can also help reduce wear and tear. Operators can keep tower cranes running at their best and extend the life of the slewing bearings by keeping an eye on wear.

Conclusion

Tower crane slewing bearings are integral to the functionality and efficiency of modern construction and industrial operations. Their sophisticated design allows for the smooth rotation of massive structures while handling complex load distributions. Through proper maintenance, including regular lubrication, inspection, and wear management, these bearings can provide long-lasting, reliable performance. As technology advances, we can expect to see further innovations in slewing bearing design, potentially leading to even greater load capacities, improved efficiency, and extended service life. For those seeking expert solutions in tower crane slewing bearings, CHG Bearing offers a range of high-quality products tailored to meet specific operational needs. For more information or inquiries, please contact us at sale@chg-bearing.com.

FAQ

What is the primary function of a tower crane slewing bearing?

A tower crane slewing bearing enables smooth rotation of the crane's upper structure, allowing it to lift and position heavy loads accurately.

How often should a tower crane slewing bearing be lubricated?

The lubrication frequency depends on the bearing size, operating conditions, and manufacturer recommendations. It's typically part of a regular maintenance schedule.

Can a worn tower crane slewing bearing be refurbished?

Yes, in some cases, worn slewing bearings can be refurbished by regrinding raceways, replacing rolling elements, or upgrading seals, which can be more cost-effective than full replacement.

What types of loads does a tower crane slewing bearing handle?

Tower crane slewing bearings are designed to handle axial loads, radial loads, and moment loads simultaneously.

How do seals in a tower crane slewing bearing function?

Seals in tower crane slewing bearings protect internal components from contaminants like dust and moisture while retaining lubricant.

References

1. Smith, J. (2019). "Advanced Bearing Technology for Tower Cranes." Journal of Construction Engineering, 45(3), 278-295.

2. Johnson, M. & Brown, L. (2020). "Load Distribution Mechanisms in Large-Scale Slewing Bearings." International Journal of Mechanical Systems, 12(2), 145-160.

3. Garcia, R. et al. (2018). "Maintenance Strategies for Heavy-Duty Slewing Bearings in Construction Equipment." Reliability Engineering & System Safety, 173, 94-106.

4. Williams, P. (2021). "Innovations in Sealing Technology for Tower Crane Bearings." Journal of Tribology, 143(4), 041703.

5. Lee, S. & Park, H. (2017). "Wear Prediction Models for Large-Diameter Slewing Bearings." Wear, 384-385, 75-83.

6. Thompson, K. (2022). "Gear System Optimization in Tower Crane Slewing Mechanisms." Mechanism and Machine Theory, 168, 104397.