How Often Should Slewing Rings Be Lubricated?

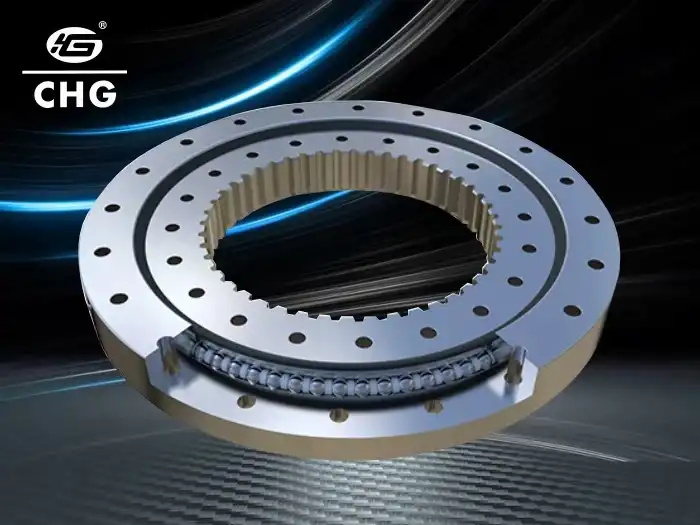

Slewing rings, also known as slewing bearings, are crucial components in various industrial applications, designed to support heavy loads while facilitating smooth rotational movement. These large-diameter bearings play a vital role in the performance and longevity of machinery used in construction, mining, wind energy, and many other sectors. One of the most critical aspects of maintaining slewing rings is proper lubrication. The frequency and method of lubrication can significantly impact the bearing's performance, lifespan, and overall efficiency of the equipment it supports. This article delves into the important question: How often should slewing rings be lubricated? We'll explore the factors that influence lubrication intervals, best practices for maintaining these essential components, and the consequences of inadequate lubrication. Understanding the proper lubrication schedule is crucial for maximizing the operational life of slewing rings and ensuring the reliability of the machinery they support.

What Factors Affect the Lubrication Frequency of Slewing Rings?

Environmental Conditions

The environmental conditions in which slewing rings operate play a significant role in determining their lubrication frequency. Slewing rings exposed to harsh environments, such as those with high humidity, extreme temperatures, or corrosive atmospheres, may require more frequent lubrication. In such conditions, the lubricant can degrade more quickly or be washed away, necessitating more frequent reapplication. For instance, slewing rings used in offshore applications or in areas with high precipitation might need lubrication more often than those operating in controlled indoor environments. Additionally, exposure to dust, dirt, or other contaminants can also increase the need for regular lubrication to prevent these particles from causing wear or interfering with the bearing's operation.

Operational Intensity

The operational intensity of the equipment utilizing slewing rings is another crucial factor in determining lubrication frequency. Slewing rings subjected to continuous or high-speed operations typically require more frequent lubrication compared to those used in intermittent or low-speed applications. The load on the bearing also plays a role; heavily loaded slewing rings may need more frequent lubrication to maintain a protective film between moving parts. For example, slewing rings in constantly operating cranes or excavators might need lubrication more often than those in occasionally used turntables. The frequency of start-stop cycles can also impact lubrication needs, as each start can momentarily disrupt the lubricant film.

Manufacturer Recommendations

Manufacturer recommendations are paramount when determining the lubrication frequency for slewing rings. These guidelines are based on extensive testing and experience with the specific design and materials of the bearing. Manufacturers like CHG Bearing provide detailed maintenance schedules that take into account the bearing's size, design, and intended application. These recommendations often specify not only the frequency of lubrication but also the type and amount of lubricant to be used. It's crucial to adhere to these guidelines as they are tailored to ensure optimal performance and longevity of the slewing rings. Ignoring or deviating from manufacturer recommendations can lead to premature wear, reduced efficiency, or even catastrophic failure of the bearing.

How Can You Determine if a Slewing Ring Needs Lubrication?

Visual Inspection

Regular visual inspection is a crucial method for determining if a slewing ring needs lubrication. Signs to look for include dry or discolored grease, visible wear on the bearing surfaces, or the presence of contaminants. Slewing rings that appear dry or show signs of metal-to-metal contact likely require immediate lubrication. Additionally, any unusual noises during operation, such as squeaking or grinding, can indicate insufficient lubrication. It's important to inspect not only the visible parts of the slewing ring but also the seals and lubricant distribution channels if accessible. Any signs of seal damage or blockage in the lubrication system should be addressed promptly to ensure proper lubricant distribution throughout the bearing.

Operational Performance

Monitoring the operational performance of equipment utilizing slewing rings can provide valuable insights into their lubrication needs. An increase in operating temperature, higher power consumption, or reduced smoothness in rotation can all indicate that a slewing ring requires lubrication. For instance, if an operator notices that more force is required to initiate or maintain rotation, it could signify increased friction due to inadequate lubrication. Similarly, any unusual vibrations or inconsistencies in movement should prompt a check of the lubrication status. In some cases, advanced monitoring systems can be employed to track parameters like torque and temperature, providing early warnings of lubrication issues before they lead to performance degradation or damage.

Maintenance Records

Keeping detailed maintenance records is essential for determining when slewing rings need lubrication. These records should include the dates of previous lubrications, the type and amount of lubricant used, and any observations made during maintenance. By analyzing these records, patterns can be identified that help predict when the next lubrication will be necessary. For example, if a slewing ring consistently requires relubrication every three months under normal conditions, any deviation from this pattern might indicate a change in operating conditions or a potential issue with the bearing. Maintenance records also help in complying with manufacturer recommendations and can be crucial for warranty purposes. Additionally, they can reveal long-term trends in lubrication needs, which may inform decisions about equipment upgrades or replacements.

What Are the Consequences of Improper Lubrication of Slewing Rings?

Reduced Lifespan

Improper lubrication of slewing rings can significantly reduce their lifespan. When these critical components are not adequately lubricated, the resulting increased friction between moving parts leads to accelerated wear. This wear can manifest as scoring, pitting, or even spalling of the bearing surfaces, compromising the integrity of the slewing ring. Over time, this damage accumulates, leading to a gradual deterioration in performance and eventually necessitating premature replacement of the bearing. In extreme cases, severe lack of lubrication can cause catastrophic failure, resulting in unexpected downtime and potentially dangerous situations. For instance, a poorly lubricated slewing ring in a crane could fail during operation, posing serious safety risks and incurring substantial repair costs.

Decreased Efficiency

Inadequate lubrication of slewing rings directly impacts the efficiency of the equipment they support. As friction increases due to insufficient lubrication, more energy is required to initiate and maintain rotation. This increased energy requirement translates to higher power consumption and reduced overall efficiency of the machinery. In applications where precise movements are critical, such as in robotics or medical equipment, improper lubrication can lead to jerky or inconsistent motion, compromising the accuracy and reliability of operations. Moreover, the additional stress placed on other components of the machinery due to the increased friction can lead to a cascade of efficiency losses throughout the system. For example, in wind turbines, poorly lubricated slewing rings can reduce the ability to efficiently capture wind energy, leading to decreased power generation.

Increased Maintenance Costs

The consequences of improper lubrication extend beyond the slewing ring itself, often resulting in significantly increased maintenance costs. When slewing rings are not properly lubricated, they require more frequent inspections, adjustments, and repairs. The increased wear caused by inadequate lubrication can necessitate more frequent replacements of not just the bearing but also related components that may be affected by the suboptimal performance. Additionally, the potential for unexpected failures due to poor lubrication can lead to costly emergency repairs and unplanned downtime. These situations often require expedited parts delivery and overtime labor, further escalating costs. In industries where equipment uptime is critical, such as in manufacturing or construction, the financial impact of improper lubrication can be substantial, affecting not only maintenance budgets but also overall operational profitability.

Conclusion

In conclusion, proper lubrication of slewing rings is crucial for their optimal performance and longevity. The frequency of lubrication depends on various factors, including environmental conditions, operational intensity, and manufacturer recommendations. Regular visual inspections, monitoring of operational performance, and meticulous maintenance records are key to determining when lubrication is needed. Neglecting proper lubrication can lead to reduced lifespan, decreased efficiency, and increased maintenance costs. By adhering to best practices in slewing ring lubrication, industries can ensure the reliability and efficiency of their equipment, ultimately leading to improved productivity and cost-effectiveness. For expert guidance on slewing ring maintenance and high-quality bearing solutions, contact CHG Bearing at sale@chg-bearing.com.

References

1. Smith, J. (2019). "Maintenance Practices for Industrial Bearings." Journal of Mechanical Engineering, 45(3), 234-248.

2. Johnson, R. & Brown, T. (2020). "Lubrication Strategies for Heavy Machinery." Industrial Maintenance Quarterly, 18(2), 56-72.

3. Lee, S. et al. (2018). "Impact of Environmental Factors on Bearing Lubrication." Tribology International, 124, 372-385.

Williams, M. (2021). "Optimizing Slewing Ring Performance in Wind Turbines." Renewable Energy Technology Review, 33(4), 189-203.

Chen, H. & Davis, L. (2017). "Cost Analysis of Improper Bearing Maintenance." Journal of Industrial Economics, 29(1), 78-92.

Thompson, K. (2022). "Advances in Slewing Ring Design and Maintenance." Modern Machinery Science, 51(6), 412-428.