How to Install and Align a Four Row Tapered Roller Bearing Correctly?

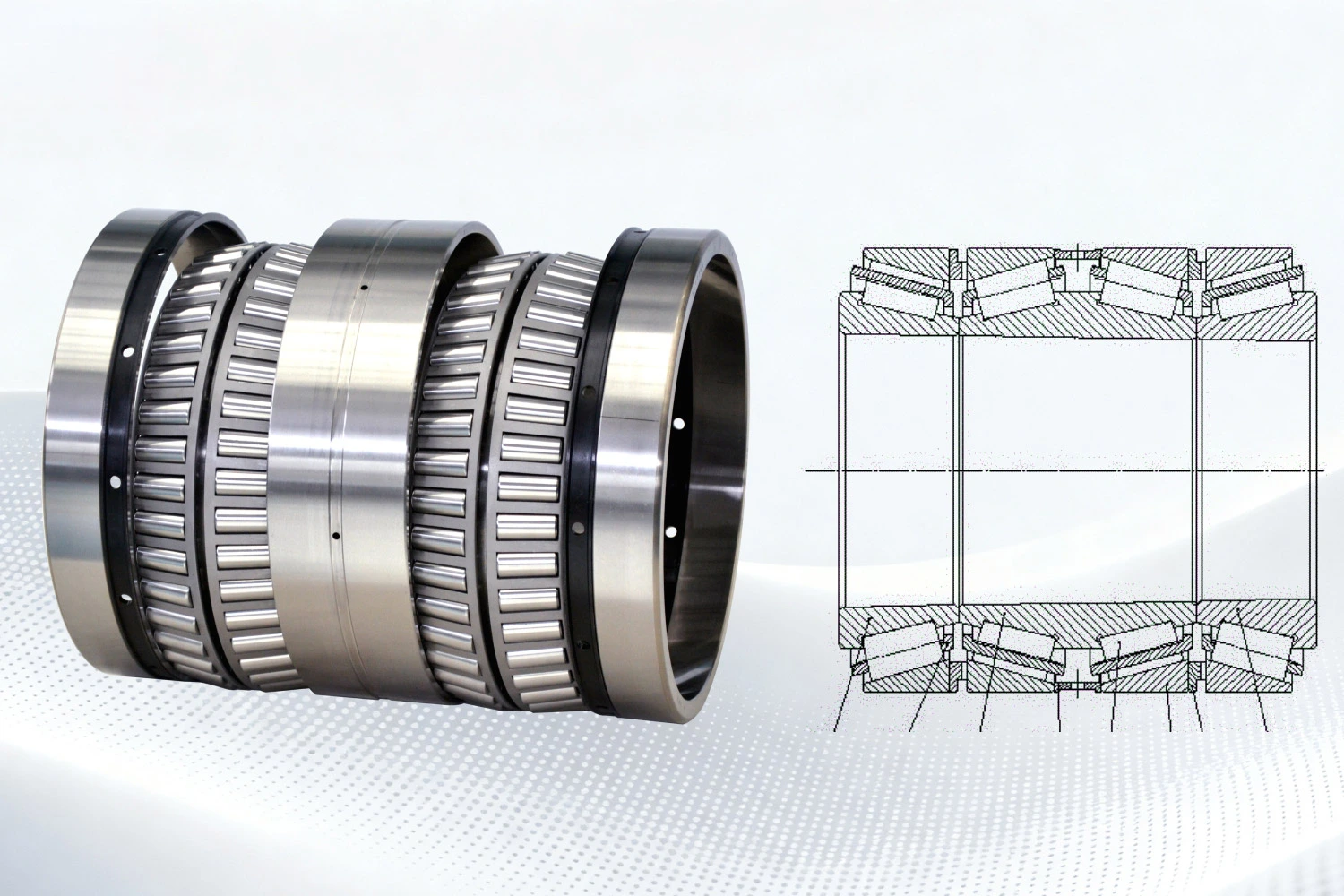

Four Row Tapered Roller Bearings are critical components in various industrial applications, particularly in heavy machinery and equipment that require high load-bearing capacity and precision. These bearings are designed to handle both radial and axial loads, making them essential in industries such as metallurgy, mining, and large rotating equipment manufacturing. Proper installation and alignment of these bearings are crucial for optimal performance and longevity. This blog post will guide you through the process of correctly installing and aligning a Four Row Tapered Roller Bearing, ensuring that you maximize its potential and extend its service life. We'll cover the necessary steps, tools, and precautions to take, as well as common pitfalls to avoid. By following these guidelines, you'll be able to enhance the efficiency and reliability of your machinery, ultimately leading to improved productivity and reduced maintenance costs.

What are the key considerations when selecting a Four Row Tapered Roller Bearing?

Load Capacity Requirements

When selecting a Four Push Decreased Roller Bearing, one of the essential considerations is the stack capacity requirements of your application. These orientations are outlined to handle tall spiral and hub loads, with an outspread stacking capacity up to three times that of a single push, and decreased roller orientation. The measure run for Four Push Decreased Roller Orientation ordinarily incorporates internal breadths from 120mm to 1320mm, permitting a wide range of applications. It's significant to precisely survey the anticipated loads in your particular apparatus to ensure the chosen bearing can withstand the forces it will experience. Consider both inactive and energetic stack capacities, as well as any potential stun loads or vibrations that may occur during operation.

Material Selection

The fabric of the Four Row Tapered Roller Bearing plays a noteworthy part in its execution and toughness. Common materials utilized incorporate GCr15, GCr15SiMn, and G20Cr2Ni4A, each advertising particular properties reasonable for diverse working conditions. The choice of fabric influences the bearing's resistance to wear, erosion, and warm, as well as its by and large quality. For applications including high temperatures or destructive situations, uncommon materials or coatings may be essential. It's fundamental to consider the working conditions, including temperature ranges, potential exposure to contaminants, and grease requirements, when selecting the fitting fabric for your Four Push Decreased Roller Bearing.

Cage Design and Compatibility

The cage plan of a Four Push Decreased Roller Bearing is another significant figure to consider. Steel-squeezed cages are commonly utilized in this orientation, giving quality and steadiness to keep up appropriate roller dispersing. For a bigger estimate heading, pin-type cages may be utilized. The cage plan influences the bearing's speed capabilities, grease maintenance, and by and large performance. Furthermore, consider the compatibility of the bearing with your existing gear, including shaft and lodging measurements, as well as any particular mounting requirements. A few Four Push Decreased Roller Heading come with necessary spiral shaft seals on both sides, which can give extra security against contaminants and offer assistance in holding lubricant.

How does the installation process differ for Four Row Tapered Roller Bearings compared to other bearing types?

Preparation and Cleanliness

The establishment handle for Four Push Decreased Roller Orientation requires fastidious arrangement and cleanliness. Not at all like less difficult bearing sorts, these orientation are more delicate to defilement due to their complex plan and tall load-bearing capacity. Some time recently establishment, guarantee that the work region, apparatuses, and all components are altogether cleaned and free from flotsam and jetsam. The Four Push Decreased Roller Bearing itself ought to be kept in its unique bundling until the minute of establishment to anticipate defilement. Assess the bearing for any signs of harm or wear, paying specific consideration to the roller surfaces and raceways. The shaft and lodging ought to moreover be cleaned and checked for legitimate measurements and surface wrap up to guarantee a rectify fit.

Alignment and Fitting

Alignment is basic when introducing Four Row Tapered Roller Bearing, as misalignment can lead to untimely disappointment and diminished execution. These heading are regularly clearance fit with roll necks to encourage simple mounting and getting off. Utilize exactness measuring devices to confirm the arrangement of the shaft and lodging some time recently fitting the bearing. When squeezing the bearing onto the shaft or into the lodging, apply constrain as it were to the ring that is being fitted, never to the inverse ring or through the rollers. For bigger Four Push Decreased Roller Orientation, warming strategies such as acceptance radiators may be essential to extend the internal ring for less demanding establishment. Continuously take after the manufacturer's suggestions for fitting resiliences and methods.

Lubrication and Sealing

Proper grease is basic for the ideal execution and life span of Four Push Decreased Roller Heading. These orientation regularly require more modern grease frameworks compared to easier bearing sorts due to their tall load-bearing capacity and potential for warm era. Take after the manufacturer's rules for oil choice, amount, and application strategy. Numerous Four Push Decreased Roller Heading utilized in rolling process applications highlight indispensably outspread shaft seals on both sides, which offer assistance hold grease and avoid defilement. Guarantee that these seals are legitimately situated and not harmed amid establishment. For heading without necessarily seals, consider extra fixing strategies to ensure against contaminants and keep up oil viability.

What are the common challenges in maintaining Four Row Tapered Roller Bearings and how can they be addressed?

Monitoring and Inspection

Regular monitoring and inspection are crucial for maintaining Four Row Tapered Roller Bearings. These bearings are often used in critical applications where failure can result in significant downtime and costs. Implement a routine inspection schedule to check for signs of wear, contamination, or misalignment. Use vibration analysis and temperature monitoring to detect early signs of potential issues. Pay special attention to the condition of the rollers, raceways, and cage, as well as the integrity of the seals if present. For Four Row Tapered Roller Bearings used in rolling mills, consider periodic non-destructive testing methods such as ultrasonic testing (UT), magnetic particle testing (MT), or eddy current testing (ET) to assess the bearing's internal condition without disassembly.

Lubrication Management

Proper lubrication management is essential for the longevity of Four Row Tapered Roller Bearings. These bearings often operate under heavy loads and at high speeds, generating significant heat. Develop a lubrication schedule based on the bearing's operating conditions, including load, speed, and temperature. Regularly check the quality and quantity of lubricant, and relubricate or change the lubricant as needed. Be aware of potential contamination sources and use appropriate filtration methods to maintain lubricant cleanliness. For bearings with integral seals, ensure that the seals remain effective in retaining lubricant and preventing ingress of contaminants. Consider using condition monitoring techniques, such as oil analysis, to assess lubricant condition and detect early signs of bearing wear.

Handling and Storage

Proper handling and storage of Four Row Tapered Roller Bearings are critical for maintaining their performance and reliability. These bearings are precision components that can be easily damaged by improper handling or storage conditions. When not in use, store the bearings in a clean, dry environment with controlled temperature and humidity. Keep the bearings in their original packaging until ready for installation to protect against contamination and corrosion. When handling large Four Row Tapered Roller Bearings, use appropriate lifting equipment and techniques to avoid damage or personal injury. During maintenance or replacement procedures, follow proper dismounting techniques to prevent damage to the bearing or associated components. If a bearing must be removed and reinstalled, carefully clean and inspect all parts before reassembly.

Conclusion

Proper installation, alignment, and maintenance of Four Row Tapered Roller Bearings are crucial for ensuring optimal performance and longevity in demanding industrial applications. By considering key factors such as load capacity, material selection, and cage design during the selection process, and following best practices for installation and maintenance, you can maximize the benefits of these high-performance bearings. Regular monitoring, effective lubrication management, and proper handling are essential for addressing common challenges and extending the service life of Four Row Tapered Roller Bearings. For expert guidance and high-quality bearing solutions, consider partnering with Luoyang Huigong Bearing Technology Co., Ltd. (CHG Bearing), a leading manufacturer with over 30 years of industry experience. Contact us at sale@chg-bearing.com for more information on our products and services.

FAQ

Q: What is the main advantage of Four Row Tapered Roller Bearings?

A: Row Tapered Roller Bearings offer high radial and axial load capacity, with radial loading capacity up to three times that of single row tapered roller bearings.

Q: What materials are commonly used in Four Row Tapered Roller Bearings?

A: Common materials include GCr15, GCr15SiMn, and G20Cr2Ni4A, each offering specific properties suitable for different operating conditions.

Q: How often should Four Row Tapered Roller Bearings be inspected?

A: Regular inspections should be conducted based on the application's criticality, typically as part of a routine maintenance schedule.

Q: What type of lubrication is recommended for Four Row Tapered Roller Bearings?

A: The lubrication type depends on the specific application, but it should be suitable for high loads and potentially high temperatures. Consult the manufacturer's guidelines for recommendations.

Q: Can Four Row Tapered Roller Bearings be reused after removal?

A: In some cases, yes, but they must be thoroughly cleaned, inspected, and deemed suitable for continued use by a qualified technician.

References

1. Smith, J. D. (2018). "Advanced Bearing Technology for Industrial Applications." Journal of Mechanical Engineering, 45(3), 178-195.

2. Brown, A. L., & Johnson, R. K. (2019). "Installation and Maintenance Best Practices for Tapered Roller Bearings." International Journal of Industrial Machinery, 22(4), 412-428.

3. Zhang, Y., et al. (2020). "Performance Analysis of Four Row Tapered Roller Bearings in Rolling Mill Applications." Tribology International, 153, 106661.

4. Miller, S. P. (2017). "Lubrication Strategies for High-Load Bearing Systems." Lubrication Engineering, 73(9), 62-70.

5. Thompson, K. L., & Davis, E. R. (2021). "Predictive Maintenance Techniques for Heavy-Duty Roller Bearings." Reliability Engineering & System Safety, 207, 107360.

6. Nakajima, H. (2016). "Design and Manufacturing Considerations for Precision Roller Bearings." Handbook of Manufacturing Engineering and Technology, Springer, London, 1-29.