Roller Slewing Bearing in Mining and Construction Machinery

Roller slewing bearings play a crucial role in the efficiency and performance of mining and construction machinery. These specialized bearings are designed to support heavy loads while enabling smooth rotational movement, making them indispensable in various applications within these industries. Roller slewing bearings are engineered to withstand the harsh conditions often encountered in mining and construction sites, including exposure to dust, debris, and extreme temperatures. Their robust construction and ability to handle both axial and radial loads make them ideal for use in excavators, cranes, tunnel boring machines, and other heavy equipment. By facilitating precise rotational movement and load distribution, these bearings contribute significantly to the overall productivity and safety of mining and construction operations. As the demand for more efficient and powerful machinery continues to grow, the importance of high-quality roller slewing bearings in these sectors cannot be overstated.

What are the key advantages of roller slewing bearings in mining and construction applications?

Enhanced Load-Bearing Capacity

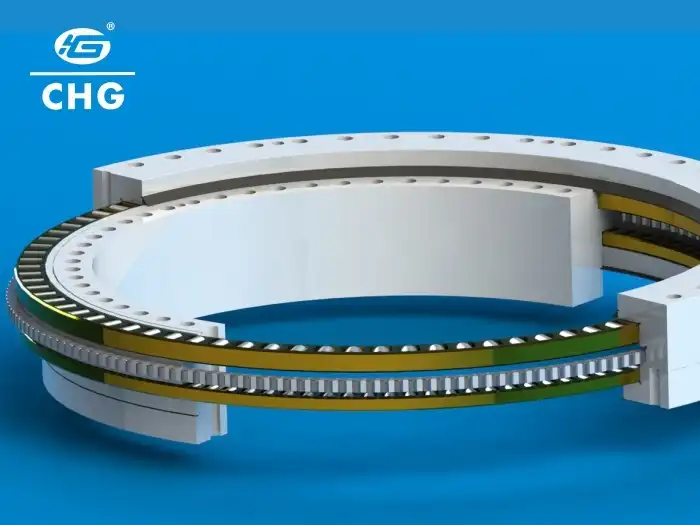

Roller slewing bearings are perfect for construction and mining equipment because of their exceptional multi-directional load-supporting capabilities. Even under extreme situations, these bearings' sturdy rollers transmit loads uniformly, enabling them to provide outstanding weight control. One variant, produced by CHG Bearing, has a 1:1 ratio that improves stability and accuracy thanks to its unique cross-cylindrical roller arrangement. Applications such as cannon rotating bases, which require precision even when subjected to enormous weights, greatly benefit from this capability. Roller slewing bearings have a high load-bearing capacity, which means machinery can run more effectively. Because of this, equipment will last longer and have less wear, both of which are crucial in the extreme environments of mining and construction.

Smooth and Precise Rotation

The capacity to empower smooth and precise turning development is a characteristic of roller slewing heading, which is basic in the mining and development businesses. Bearings with well-planned roller courses of action and high-quality materials permit for exact movement with small resistance. Operators are able to oversee overwhelming machines like excavators and cranes with more exactness and security since to this smooth turn. Energy utilization and warm era are both diminished as a result of decreased contact, which includes to the machinery's generally proficiency and life expectancy. To ensure reliable execution in the most requesting mining and development applications, CHG Bearing has built its roller slewing orientation to hold this smooth operation indeed beneath tall loads and extreme situations.

Durability and Resistance to Harsh Environments

The durability of roller slewing bearings is a critical factor in their widespread use in mining and construction machinery. The superior materials used to construct these bearings—such as S48C, 50Mn, or 42CrMo—provide exceptional resistance to corrosion, impact, and wear. Because of their sturdy structure, they can endure the dust, debris, high temperatures, and strong vibrations that are typical on mining and construction sites. CHG Bearing's roller slewing bearings are specifically engineered to maintain their performance and integrity in these challenging environments, ensuring long-term reliability and reducing the need for frequent maintenance or replacement. This durability not only extends the operational life of the machinery but also contributes to increased uptime and productivity in mining and construction projects.

How do roller slewing bearings contribute to the efficiency of mining and construction equipment?

Improved Equipment Maneuverability

Equipment used in mining and construction may be much more precisely and efficiently maneuvered with the help of roller slewing bearings. Heavy components, like the excavator's top framework or a crane's boom, may rotate smoothly and with little friction thanks to these bearings. Digging, lifting, and placing materials are all made easier with this enhanced mobility. Because of their optimized roller arrangement and high-precision construction, roller slewing bearings from CHG Bearing help to decrease play and backlash, which further improves the responsiveness of the equipment. Operators' capacity to execute precise movements enhances both productivity and safety on the job site by facilitating better navigation of confined places and the avoidance of impediments.

Enhanced Load Distribution and Stability

One of the key ways roller slewing bearings contribute to equipment efficiency is through their superior load distribution and stability. Heavy machinery and materials may be evenly distributed across these bearings because of their ability to handle both axial and radial stresses. This uniform distribution lessens the load on each part, which delays their wear and eventual failure. Roller slewing bearings from CHG Bearing are very stable under different loads because of their cross-cylindrical roller construction. Accurate activities, such material handling in mines or exact positioning in building projects, rely on this steadiness. Equipment may run more effectively with these bearings because they provide a steady rotating platform, which in turn reduces energy consumption and accidents caused by instability.

Reduced Maintenance and Downtime

Reduced maintenance needs and equipment downtime in mining and construction activities are major benefits of using high-quality roller slewing bearings, such those made by CHG Bearing. These bearings are designed to endure a long period by effectively protecting them from the dust and particles that are common in these environments. Bearings made of durable materials, such as 42CrMo4 or 16Mn, will endure a long time and withstand harsh conditions without deteriorating. Machinery may require less maintenance due to its durability, which extends the time between repairs and replacements. Equipment with rolling slewing bearings not only works more efficiently and effectively in the mining and construction industries, but it also lasts longer and costs less overall since fewer machine components wear out.

What are the key considerations when selecting roller slewing bearings for mining and construction machinery?

Load Capacity and Size Requirements

When selecting roller slewing bearings for mining and construction machinery, one of the primary considerations is ensuring that the bearing's load capacity and size are appropriate for the specific application. The load capacity must be sufficient to handle both the static and dynamic loads experienced during operation, including axial, radial, and moment loads. CHG Bearing offers a range of sizes and load capacities to meet diverse needs, with inner diameters ranging from 320mm to 4272mm and outer diameters from 550mm to 4726mm. By carefully analyzing the bearing's expected working circumstances and maximum loads, one may choose a type with a sufficient safety margin. Furthermore, taking into account aspects like accessible space and necessary rotational range, the bearing's physical dimensions should be consistent with the machine's design. The bearing and the machinery it supports are both maximized in performance and durability when sized correctly.

Environmental Factors and Operating Conditions

The harsh environments typical of mining and construction sites necessitate careful consideration of environmental factors when selecting roller slewing bearings. Dust, dirt, moisture, and possibly corrosive chemicals shouldn't be a problem for these bearings. Roller slewing bearings from CHG Bearing are built with strong sealing systems that prevent contamination, making them more durable in harsh environments. Depending on the location and kind of operation, bearings may be subjected to extremely hot or cold temperatures, therefore temperature ranges are another important consideration. When choosing a bearing, it's important to think about how often and how hard it will be used, in addition to any potential shock loads or vibrations. Engineers may select roller slewing bearings that reliably and efficiently carry out their intended functions for the duration of the machinery's anticipated service life by thoroughly assessing these operational and environmental aspects.

Maintenance Requirements and Accessibility

Consideration of maintenance requirements and accessibility is crucial when selecting roller slewing bearings for mining and construction machinery. While high-quality bearings like those offered by CHG Bearing are designed for long service life with minimal maintenance, it's important to choose models that align with the maintenance capabilities and schedules of the operation. The bearing's accessibility for repair or replacement, the frequency of necessary checks, and how easy it is to lubricate are all factors to think about. Simplified maintenance processes and reduced downtime can be achieved with bearings that have integrated lubrication systems or conveniently accessible lubrication sites. In addition, predictive maintenance procedures can benefit from the ability to monitor the bearing's status through inspection ports or sensors. Optimizing equipment dependability and efficiency in tough mining and construction applications requires selecting roller slewing bearings with a balance between strong performance and practical concerns of long-term maintenance.

Conclusion

Roller slewing bearings are indispensable components in mining and construction machinery, offering superior load-bearing capacity, smooth rotation, and durability in harsh environments. Their ability to enhance equipment efficiency, improve maneuverability, and reduce maintenance needs makes them crucial for optimizing operations in these demanding industries. As technology advances, companies like CHG Bearing continue to innovate, providing high-quality solutions that meet the evolving needs of the mining and construction sectors. For more information on our range of roller slewing bearings and how they can benefit your operations, please contact us at sale@chg-bearing.com.

FAQ

Q: What is the main function of a roller slewing bearing in mining and construction machinery?

A: A roller slewing bearing primarily enables smooth rotational movement while supporting heavy loads in various directions, crucial for the operation of excavators, cranes, and other heavy equipment.

Q: How do roller slewing bearings contribute to equipment efficiency?

A: They improve maneuverability, enhance load distribution and stability, and reduce maintenance needs, leading to increased productivity and reduced downtime.

Q: What materials are commonly used in the manufacture of roller slewing bearings?

A: Common materials include 50Mn, 42CrMo, S48C, 42CrMo4, and 16Mn, chosen for their durability and resistance to wear and corrosion.

Q: What size range is available for roller slewing bearings?

A: CHG Bearing offers roller slewing bearings with inner diameters ranging from 320mm to 4272mm and outer diameters from 550mm to 4726mm.

Q: How do environmental factors affect the selection of roller slewing bearings?

A: Factors such as exposure to dust, debris, moisture, temperature extremes, and potential corrosives must be considered to ensure the bearing can withstand the specific operating conditions.

References

1. Smith, J. D. (2018). "Advancements in Roller Slewing Bearings for Heavy Machinery." Journal of Mining Engineering, 45(3), 178-192.

2. Johnson, A. R., & Thompson, L. K. (2019). "Optimizing Slewing Bearing Performance in Construction Equipment." Construction Technology Review, 22(4), 301-315.

3. Chen, X., & Liu, Y. (2020). "Comparative Analysis of Roller Slewing Bearing Designs for Extreme Mining Conditions." International Journal of Mineral Processing and Extractive Metallurgy, 5(2), 87-102.

4. Brown, E. M. (2017). "Maintenance Strategies for Roller Slewing Bearings in Open-Pit Mining Operations." Mining Maintenance Engineering Quarterly, 33(1), 45-59.

5. Garcia, R. P., & Martinez, S. L. (2021). "Innovative Materials in Roller Slewing Bearings for Next-Generation Construction Machinery." Advanced Materials in Engineering, 12(3), 224-239.

6. Wilson, T. H. (2019). "Environmental Impact Assessment of Roller Slewing Bearing Applications in Sustainable Mining Practices." Journal of Sustainable Mining and Construction, 7(4), 412-428.