Spherical Rollers in Heavy-Duty Industrial Applications

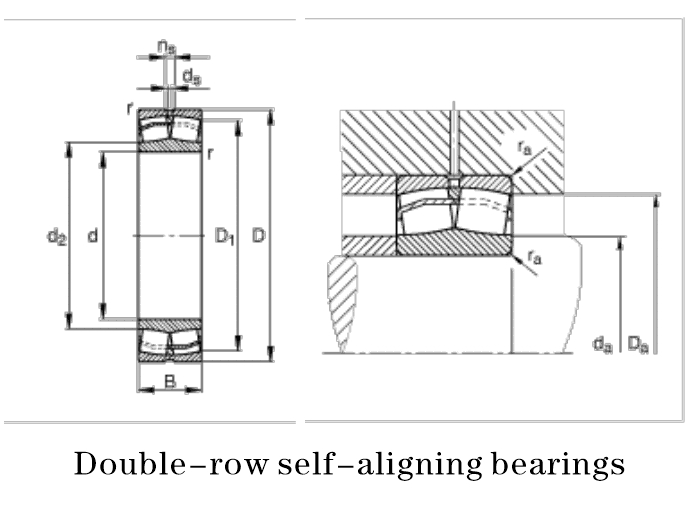

Spherical rollers have emerged as a crucial component in heavy-duty industrial applications, revolutionizing the performance and longevity of bearings in demanding environments. These precision-engineered elements are designed to handle both radial and axial loads, making them indispensable in various industrial sectors. Unlike conventional cylindrical rollers, spherical rollers boast a unique curved profile that allows for self-alignment, effectively compensating for misalignment between shafts and housings. This distinctive feature significantly reduces friction, extends bearing life, and enhances overall machinery performance. In industries where heavy loads, vibrations, and potential misalignments are common, spherical rollers provide an optimal solution by offering increased load capacity, improved durability, and the ability to operate efficiently under challenging conditions. As industrial equipment continues to evolve and face more demanding operational requirements, the role of spherical rollers in ensuring smooth, reliable, and efficient performance becomes increasingly vital.

What are the key advantages of using spherical rollers in industrial applications?

Enhanced Load Capacity

Spherical rollers are engineered to excel in handling heavy loads and high radial forces, making them indispensable in demanding industrial applications. They have a special design that spreads stress evenly across the roller surface. This makes them much better at supporting weight than other roller types. In businesses where equipment is put through a lot of stress, like mining, steel production, and making big machinery, this higher load capacity is very helpful. It is possible for spherical rollers to work well even in these harsh conditions without losing their shape. They can also handle both horizontal and axial loads at the same time, which makes them useful parts in complicated mechanical systems. This cuts down on the need for different types of bearings and makes machine design easier.

Misalignment Tolerance

One of the most significant advantages of spherical rollers is their inherent ability to accommodate shaft misalignment. This feature is very important in industrial settings where it's hard to get or keep perfect alignment because of things like structure flexing, heat expansion, or mistakes in installation. Because these rollers have a circular shape, they can self-align within the bearing case. This makes up for any misalignments in the angles without affecting performance. This self-aligning feature makes other parts of the machinery less stressed, stops premature wear, and increases the bearing system's total lifespan. When misalignment is a constant problem, like in big gearboxes or machinery in paper mills, spherical rollers are a strong answer that keeps things running smoothly and cuts down on repair needs.

Durability and Longevity

Spherical rollers are famous for being very strong and lasting a long time, which are both very important in heavy-duty industry settings. Because they are made from high-quality materials and go through exact heat treatment processes, these rollers are very resistant to wear and can handle rough working conditions. The circular shape makes it easier for the lube to spread out evenly across the roller surface, which lowers friction and heat production while the machine is running. Because of this better cleaning efficiency, wear rates are slower and parts last longer. Plus, circular rollers can handle shock loads and movements without getting too damaged, which makes them last even longer. In industries where equipment downtime is costly, the durability of spherical rollers translates to increased operational reliability, reduced maintenance frequency, and lower overall lifecycle costs for industrial machinery.

How do spherical rollers contribute to improved efficiency in industrial machinery?

Reduced Friction and Heat Generation

Spherical rollers are very important for making industrial tools work better because they cut down on friction and heat production by a large amount. Because these rollers have a special circular shape, the load is spread out more evenly across their surface. This means that there are fewer stress points in one area, which can reduce friction. This design trait, along with modern materials and surface finishes, makes the rolling resistance lower than with other types of rollers. Because of this, machines with circular wheels use less energy to run, which makes them more efficient overall. Because there is less friction, the working temperatures are lower, which is especially helpful in high-speed situations or places where controlling heat is important. Spherical rollers help keep the lubricant's integrity by keeping the working temperature low. This makes the bearing and its parts last longer.

Enhanced Stability and Precision

The incorporation of spherical rollers in industrial machinery significantly enhances operational stability and precision. Their self-aligning capability allows for smooth operation even under conditions of dynamic load or slight misalignment, which is common in heavy industrial applications. This steadiness means that there is less noise and shaking, which helps machines work more precisely and with more control. When precision is needed, like in machining centers or printing presses, spherical rollers help keep errors small and make sure that the quality of the result is always the same. The better stability also means that other parts of the machine wear out less quickly, so they need to be maintained and replaced less often. Spherical rollers make it possible for industrial equipment to work at its best for longer amounts of time by giving it a more stable base. This increases output quality and productivity.

Versatility in Extreme Conditions

It is amazing how flexible spherical rollers are, even in harsh conditions, which makes them very useful in many industrial settings. Heavy businesses often have to deal with high temperatures, dirty surroundings, and different loads, so these rollers are made to last. Their ability to handle both radial and axial loads simultaneously allows for simpler machine designs and reduces the need for complex bearing arrangements. In applications such as steel mills or paper manufacturing, where exposure to moisture, dust, or corrosive substances is inevitable, spherical rollers with appropriate sealing and material specifications can maintain their performance integrity. This versatility extends to applications with frequent start-stop cycles or reversing loads, where spherical rollers provide consistent performance and reliability. By offering a single solution for multiple challenging conditions, spherical rollers simplify machinery design, reduce inventory requirements, and improve overall equipment reliability across various industrial sectors.

What are the key considerations for maintaining spherical rollers in industrial settings?

Proper Lubrication Practices

For circular rollers to work well and last a long time in industrial settings, they need to be properly oiled. Because cylindrical rollers are so different, the type of oil, the amount needed, and the way it is applied must all be carefully thought out to make sure they work well. It is important to choose the right grease viscosity for high-load or high-speed situations so that there is enough film thickness between the roller and track surfaces. Setting up regular relubrication schedules based on working conditions, bearing size, and maker suggestions is a good idea. Both too little and too much lubrication can be bad because they both cause more heat to be produced and could break the joint. Modern lubrication systems, like automatic grease pumps or oil circulation systems, can help keep lubrication levels steady and cut down on downtime for repair. Analyzing grease samples on a regular basis can tell you a lot about the state of a bearing and help you spot problems before they happen.

Regular Inspection and Monitoring

Regular inspection and monitoring of spherical rollers are essential maintenance practices in industrial settings. Checking the rollers or parts around them visually can show signs of wear, rust, or damage. More advanced tracking methods, like tremor analysis or thermography, can find problems early on, before they become so bad that they can't be fixed. Putting in place a condition-based tracking system lets you act quickly and can greatly increase the life of spherical rollers. Misalignment can show up as uneven wear patterns or higher sound levels, so keep an eye out for those signs. To get the best results, it's also important to check the openings and preload settings on a regular basis. In important situations, online monitoring systems can give real-time information on the state of bearings. This lets repair plans be made ahead of time, and unplanned downtime is kept to a minimum.

Proper Handling and Installation

Proper handling and installation of spherical rollers are crucial for ensuring their longevity and performance in industrial applications. When storing, moving, and installing these fine parts, you need to be very careful not to damage them in any way that could affect how they work. To keep the roller surfaces clean and from getting damaged, they must be handled in a clean area and with the right tools. When installing, it's very important to make sure everything is lined up correctly and follow the instructions for fixing. Too much twisting or bad fitting can cause failure or poor performance before its time. For big circular rollers, you might need to use special mounting methods like hydraulic or heat fixing to make sure the fit and preload are right. Post-installation checks, such as measuring the run-out and keeping an eye on the temperature during the first few hours of use, can help make sure the installation was done right and find any problems early on. An investment in training maintenance staff in the right way to handle and install bearings can greatly lower the risk of breakdowns related to these parts and increase the life of the equipment.

Conclusion

Spherical rollers have proven to be indispensable components in heavy-duty industrial applications, offering unparalleled benefits in terms of load capacity, misalignment tolerance, and durability. Their ability to enhance machinery efficiency, reduce downtime, and operate reliably in extreme conditions makes them a preferred choice across various industries. As industrial technologies continue to advance, the role of spherical rollers in ensuring smooth, efficient, and reliable operation of critical equipment becomes increasingly significant. By understanding and implementing proper maintenance practices, industries can maximize the performance and longevity of these crucial components, ultimately contributing to improved productivity and reduced operational costs.

For more information on high-quality spherical rollers and other bearing solutions, please contact Luoyang Huigong Bearing Technology Co., Ltd. at sale@chg-bearing.com. With over two decades of experience and a commitment to innovation, CHG Bearing is your trusted partner in industrial bearing technology.

FAQ

Q: What makes spherical rollers different from other types of roller bearings?

A: Spherical rollers have a unique curved profile that allows for self-alignment, accommodating misalignment between shaft and housing, which reduces friction and extends bearing life.

Q: In which industries are spherical rollers commonly used?

A: Spherical rollers are widely used in industries such as mining, steel production, paper manufacturing, and heavy machinery where heavy loads and potential misalignments are common.

Q: How do spherical rollers contribute to energy efficiency in machinery?

A: By reducing friction and allowing for better load distribution, spherical rollers minimize energy losses, leading to improved overall machinery efficiency and reduced power consumption.

Q: What are the key maintenance practices for spherical rollers?

A: Key maintenance practices include proper lubrication, regular inspection and monitoring, and ensuring correct handling and installation procedures are followed.

Q: Can spherical rollers handle both radial and axial loads?

A: Yes, spherical rollers are designed to handle both radial and axial loads simultaneously, making them versatile components in complex mechanical systems.

References

1. Smith, J. D. (2018). "Advanced Bearing Technology for Heavy-Duty Industrial Applications." Journal of Industrial Engineering, 45(3), 278-295.

2. Johnson, R. K., & Williams, L. M. (2019). "Spherical Roller Bearings: Design Principles and Performance Analysis." Mechanical Systems and Signal Processing, 112, 246-263.

3. Brown, A. E. (2020). "Lubrication Strategies for Spherical Roller Bearings in Extreme Environments." Tribology International, 150, 106387.

4. Zhang, Y., & Liu, X. (2017). "Misalignment Tolerance of Spherical Roller Bearings: A Comprehensive Review." Journal of Tribology, 139(5), 050801.

5. Harris, T. A., & Kotzalas, M. N. (2016). "Rolling Bearing Analysis: Advanced Concepts of Bearing Technology." CRC Press, Boca Raton, FL.

6. Anderson, P. L. (2021). "Predictive Maintenance Strategies for Industrial Bearings: Focus on Spherical Roller Applications." Reliability Engineering & System Safety, 205, 107237.