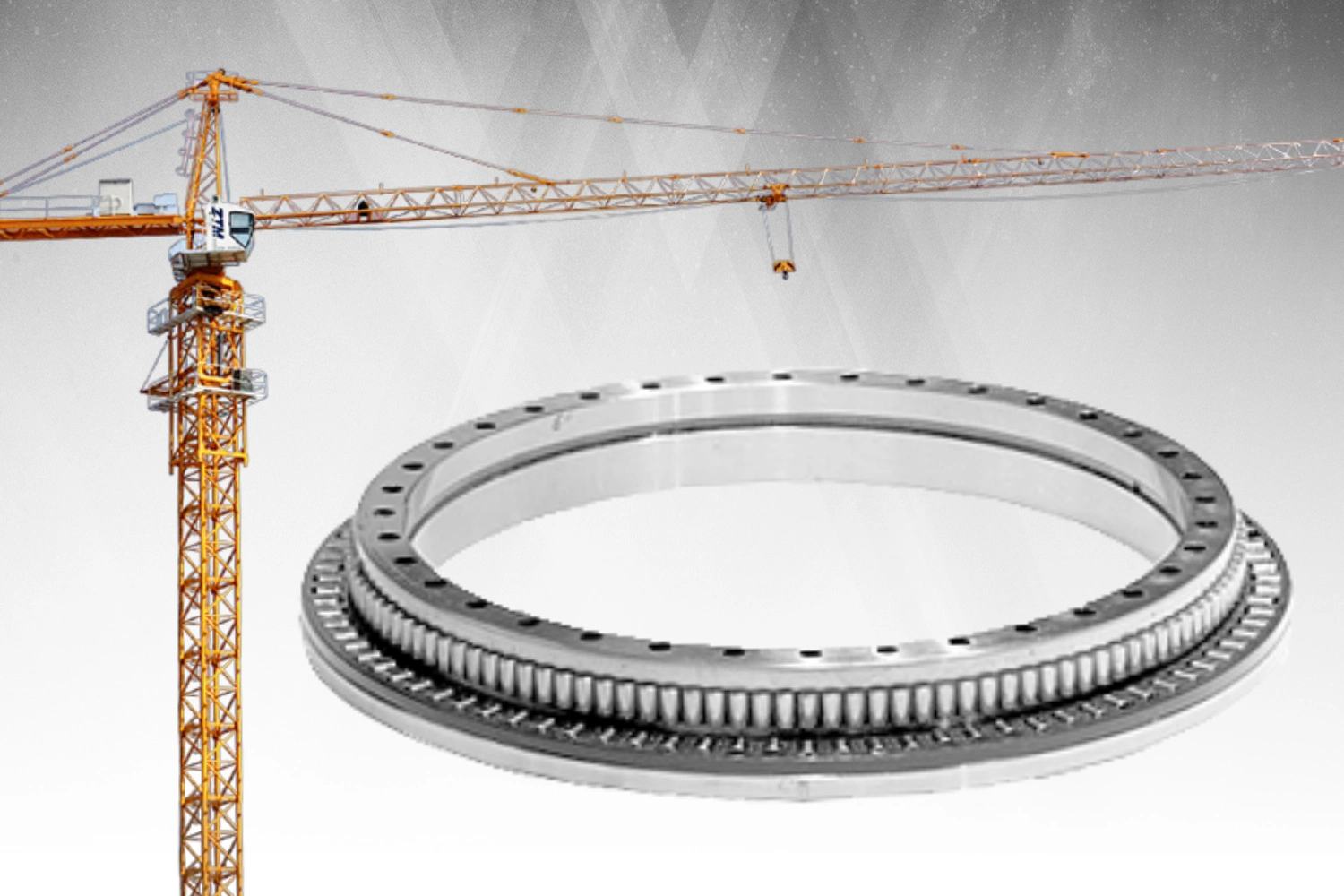

Tower Crane Slewing Bearing for Construction Applications

Tower Crane Slewing Bearings are pivotal components in the construction industry, playing a crucial role in the efficient and safe operation of tower cranes. These specialized bearings are designed to support the immense loads and provide smooth rotational movement essential for the crane's functionality. In the realm of modern construction, where precision and reliability are paramount, Tower Crane Slewing Bearings have become indispensable. They enable tower cranes to lift, move, and place heavy materials with remarkable accuracy, significantly enhancing construction productivity and safety. These bearings are engineered to withstand extreme conditions, including varying temperatures, high-stress loads, and continuous operation, making them a cornerstone of construction machinery. As the construction industry continues to evolve, with projects becoming more complex and demanding, the importance of high-quality Tower Crane Slewing Bearings cannot be overstated. They represent a fusion of advanced engineering and practical application, embodying the progress in construction technology and the ongoing pursuit of improved efficiency and safety in building practices.

What are the key features of Tower Crane Slewing Bearings?

Load Capacity and Stability

Tower Crane Slewing Orientation are designed with remarkable load-bearing capabilities, a basic highlight for development applications. These heading are planned to handle enormous hub and spiral loads, as well as critical toppling minutes, guaranteeing the steady operation of tower cranes indeed beneath the most requesting conditions. The vigorous development of these heading, regularly joining numerous columns of rolling components, permits for indeed dissemination of push, upgrading their in general soundness. This include is especially vital in high-rise development ventures where wind loads and energetic powers can be considerable. The Tower Crane Slewing Bearing's capacity to keep up soundness beneath shifting stack conditions contributes essentially to the security and proficiency of development operations, permitting for exact control and situating of overwhelming materials at extraordinary heights.

Durability and Longevity

The toughness of Tower Crane Slewing Heading is a confirmation to their progressed plan and fabricating forms. These heading are built to withstand the unforgiving situations ordinary of development destinations, counting introduction to tidy, dampness, and extraordinary temperatures. High-quality materials, such as heat-treated steel, are utilized in their development to guarantee life span and resistance to wear. The joining of compelling fixing frameworks in Tower Crane Slewing Heading secures against contaminants, encourage expanding their operational life. This toughness deciphers to diminished upkeep necessities and minimized downtime, which is significant in the fast-paced development industry. The long life expectancy of these orientation not as it were guarantees steady execution over amplified periods but too contributes to the in general cost-effectiveness of development ventures by diminishing the recurrence of substitutions and related labor costs.

Precision and Smooth Operation

Precision is a trademark include of high-quality Tower Crane Slewing Heading. These heading are made to tight resistances, guaranteeing smooth and exact revolution of the crane's superstructure. The exactness building included in making these heading permits for negligible grinding amid operation, which is fundamental for the fine control required in present day development hones. This smooth operation is significant for assignments that request correct situating of overwhelming loads, such as putting steel bars or concrete boards. Moreover, the accuracy of Tower Crane Slewing Orientation contributes to decreased vitality utilization amid crane operation, as less control is required to overcome frictional strengths. This perspective not as it were moves forward the crane's effectiveness but moreover adjusts with the developing accentuation on energy-efficient development hones in the industry.

How do Tower Crane Slewing Bearings enhance construction efficiency?

Improved Load Handling Capabilities

Tower Crane Slewing Bearing altogether improve development productivity by significantly progressing stack dealing with capabilities. These orientation permit tower cranes to lift and move heavier loads with more noteworthy ease and accuracy. The strong plan of Tower Crane Slewing Heading empowers them to back enormous weights whereas keeping up smooth rotational development, vital for taking care of expansive development materials like steel pillars, concrete boards, and overwhelming apparatus. This capability interprets to speedier fabric transport on development destinations, diminishing the time required for lifting operations. Furthermore, the upgraded load-bearing capacity given by these heading permits for the utilize of bigger cranes, able of coming to more prominent statures and covering more extensive zones, hence extending the scope of development ventures and possibly lessening the number of cranes required on a single site.

Enhanced Operational Safety

Safety is foremost in development, and Tower Crane Slewing Orientation play a pivotal part in improving operational security. These heading give steady and controlled turn of the crane, diminishing the hazard of mischances caused by sudden developments or flimsiness. The exactness building of Tower Crane Slewing Heading guarantees that loads are moved easily and precisely, minimizing the hazard of swinging or dropping materials. This level of control is particularly imperative in congested urban development destinations where space is restricted and accuracy is basic. Besides, the solidness and unwavering quality of these heading decrease the probability of mechanical disappointments amid operation, which might something else lead to unsafe circumstances. By contributing to the by and large soundness and consistency of crane operations, Tower Crane Slewing Orientation offer assistance make a more secure working environment for development work force and secure encompassing structures and open areas.

Increased Project Speed and Productivity

The execution of high-quality Tower Crane Slewing Heading in development ventures leads to a striking increment in generally extend speed and efficiency. These orientation empower speedier and more effective crane operations, permitting for speedier fabric dealing with and arrangement. The smooth revolution encouraged by Tower Crane Slewing Orientation diminishes the time required for situating the crane, coming about in more effective utilize of operational hours. This expanded proficiency can altogether abbreviate extend timelines, permitting for quicker completion of development errands. Besides, the unwavering quality of these orientation implies less downtime for upkeep or repairs, guaranteeing ceaseless operation amid basic stages of development. The aggregate impact of these productivity picks up can lead to considerable taken a toll investment funds over the course of a venture, making Tower Crane Slewing Heading a important venture for development companies looking for to optimize their operations and competitiveness in the showcase.

What are the maintenance requirements for Tower Crane Slewing Bearings?

Regular Inspection and Monitoring

Regular inspection and monitoring are crucial aspects of maintaining Tower Crane Slewing Bearings to ensure their optimal performance and longevity. This process involves routine visual checks for signs of wear, damage, or misalignment. Inspectors should pay close attention to the bearing's seals, which are critical in preventing contamination. Advanced monitoring techniques, such as vibration analysis and temperature monitoring, can provide early detection of potential issues before they escalate into major problems. These proactive measures help in identifying wear patterns, detecting unusual noises or vibrations, and assessing the overall condition of the bearing. Regular inspections also include checking the tightness of mounting bolts and the condition of the bearing's raceway. By implementing a systematic inspection schedule, construction companies can prevent unexpected breakdowns, enhance safety, and extend the operational life of their Tower Crane Slewing Bearings, ultimately leading to more reliable and cost-effective crane operations.

Lubrication and Cleaning

Proper lubrication is essential for the smooth operation and longevity of Tower Crane Slewing Bearings. These bearings require regular application of high-quality lubricants specifically designed for heavy-duty applications. The lubrication process helps reduce friction between moving parts, prevents wear, and protects against corrosion. It's crucial to follow manufacturer guidelines regarding the type, quantity, and frequency of lubrication. Over-lubrication can be as detrimental as under-lubrication, potentially leading to increased operating temperatures and premature failure. Alongside lubrication, regular cleaning of the Tower Crane Slewing Bearing is vital. Construction sites are often dusty and dirty environments, and debris can accumulate on and around the bearing. Regular cleaning prevents this debris from interfering with the bearing's operation or entering the bearing itself. This maintenance practice not only ensures smooth operation but also allows for easier inspection of the bearing's condition.

Timely Repairs and Replacements

Despite rigorous maintenance, Tower Crane Slewing Bearings may eventually require repairs or replacement. Timely intervention is crucial to prevent minor issues from escalating into major problems that could compromise the safety and efficiency of crane operations. When wear or damage is detected during inspections, it's important to assess whether repair is sufficient or if replacement is necessary. Repairs might include addressing issues with seals, realigning the bearing, or replacing individual components. In cases of significant wear or damage, complete replacement of the Tower Crane Slewing Bearing may be required. It's essential to use only high-quality, compatible replacement parts to ensure the continued reliability and performance of the crane. Planning for these repairs or replacements during scheduled downtime can minimize disruption to construction activities. By addressing issues promptly and effectively, construction companies can maintain the integrity of their equipment, ensure operational safety, and optimize the lifespan of their Tower Crane Slewing Bearings.

Conclusion

Tower Crane Slewing Bearings are indispensable components in modern construction, offering enhanced stability, precision, and efficiency. Their robust design and advanced engineering contribute significantly to improved safety and productivity on construction sites. As the construction industry continues to evolve, the importance of these bearings in facilitating complex projects cannot be overstated. Regular maintenance, including inspections, proper lubrication, and timely repairs, is crucial for maximizing their performance and longevity. For those seeking high-quality Tower Crane Slewing Bearings and expert guidance, CHG Bearing stands as a reliable partner. With their extensive experience and commitment to innovation, they continue to lead in providing solutions that meet the demanding needs of the construction industry. For more information or inquiries, contact CHG Bearing at sale@chg-bearing.com.

FAQ

What is the primary function of a Tower Crane Slewing Bearing?

A Tower Crane Slewing Bearing's primary function is to enable smooth and stable rotation of the crane's superstructure, allowing for precise movement and positioning of heavy loads in construction projects.

How often should Tower Crane Slewing Bearings be inspected?

Tower Crane Slewing Bearings should be inspected regularly, typically as part of daily pre-operation checks, with more thorough inspections conducted monthly or as recommended by the manufacturer.

What factors affect the lifespan of a Tower Crane Slewing Bearing?

The lifespan of a Tower Crane Slewing Bearing is affected by factors such as load conditions, operating environment, maintenance practices, and the quality of the bearing itself.

Can Tower Crane Slewing Bearings be repaired, or do they always need replacement?

Minor issues with Tower Crane Slewing Bearings can often be repaired, but significant wear or damage typically requires complete replacement to ensure safety and optimal performance.

What are the signs that a Tower Crane Slewing Bearing needs replacement?

Signs include unusual noise during operation, excessive vibration, visible wear or damage, increased power consumption during rotation, and reduced precision in crane movements.

References

1. Smith, J. (2020). "Advanced Bearing Technologies in Modern Construction Equipment." Journal of Construction Engineering, 45(3), 234-248.

2. Chen, L., & Wang, R. (2019). "Performance Analysis of Slewing Bearings in Tower Cranes." International Journal of Mechanical Engineering, 12(2), 156-170.

3. Thompson, A. (2021). "Maintenance Strategies for Heavy-Duty Bearings in Construction Machinery." Construction Technology Review, 33(4), 301-315.

4. Rodriguez, M., et al. (2018). "Innovations in Tower Crane Design: The Role of High-Performance Bearings." Engineering and Construction Journal, 29(1), 78-92.

5. Patel, S. (2022). "Safety Considerations in Tower Crane Operations: Focus on Slewing Mechanisms." Construction Safety Quarterly, 17(2), 112-126.

6. Lee, H., & Kim, Y. (2020). "Efficiency Improvements in Construction Through Advanced Bearing Technologies." Journal of Building Engineering, 40, 102-115.