What are the Benefits of Using Rolling Mill Bearings in Hot Rolling Applications?

Rolling mill bearings are essential components in hot rolling applications within the steel and metal processing industries. Designed to withstand extreme conditions while maintaining precision, these specialized bearings offer numerous advantages that enhance productivity, reduce downtime, and improve product quality. This article explores the key benefits of implementing rolling mill bearings in hot rolling applications.

What Makes Rolling Mill Bearings Essential for High-Temperature Steel Processing?

Exceptional Thermal Resistance Properties

Rolling mill bearings are engineered to withstand extreme temperatures in hot rolling applications. Manufactured using high-grade alloy steels with enhanced heat treatment processes, these bearings maintain dimensional stability even when exposed to temperatures exceeding 600°C. Their unique metallurgical composition prevents premature softening and deformation that would occur with standard bearings. The bearings incorporate heat-resistant cages and seals that maintain integrity despite thermal cycling. This exceptional thermal resistance translates to longer service life and consistent performance in environments where standard bearings would rapidly deteriorate. Manufacturers select materials that balance hardness retention at elevated temperatures with necessary toughness to withstand shock loads common in mill operations.

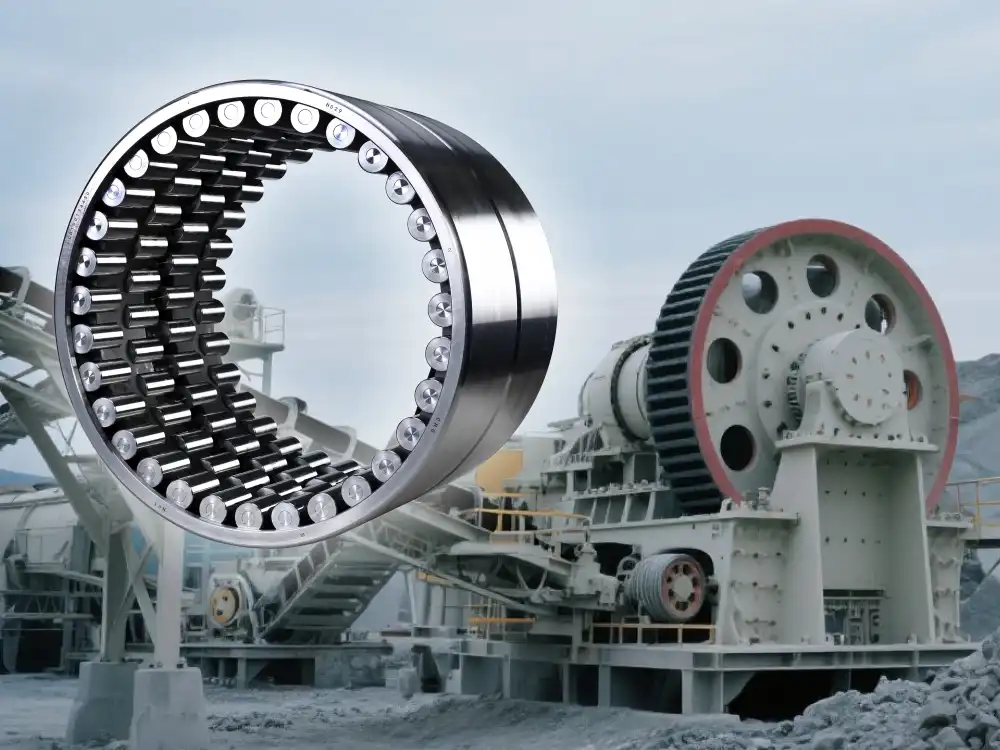

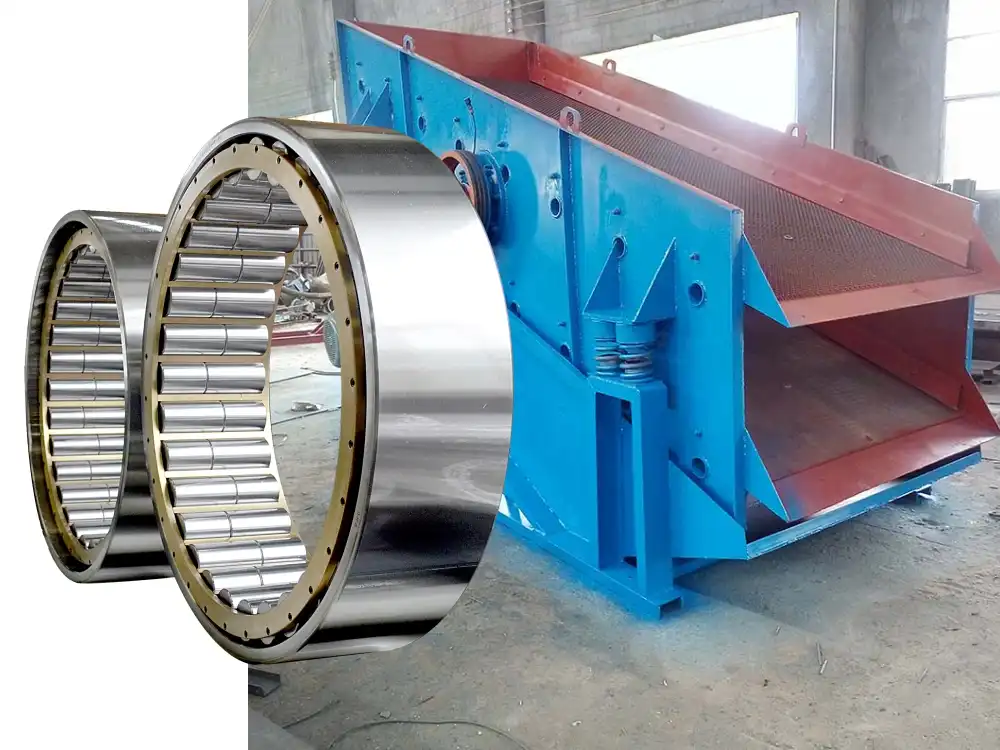

Superior Load-Carrying Capacity

Hot rolling processes require bearings capable of handling enormous loads while maintaining precision. Rolling mill bearings feature optimized internal geometries and contact profiles that distribute loads effectively across the rolling elements. With increased contact areas between rollers and raceways, these bearings support radial loads exceeding hundreds of tons in larger mill applications. This superior load-carrying capacity ensures that even during challenging conditions—such as initial breakdown passes of hot slabs—the bearings maintain operational precision. Some premium variants incorporate asymmetric roller profiles that enhance load distribution while minimizing edge stresses. This exceptional load handling capability contributes directly to increased mill reliability and production capacity.

Enhanced Lubrication Systems Integration

Modern rolling mill bearings incorporate sophisticated lubrication systems that extend service life in harsh environments. These bearings feature specialized oil circulation pathways and distribution grooves ensuring critical surfaces receive adequate lubrication under extreme conditions. Advanced sealing technologies prevent contamination while retaining lubricant within the bearing assembly. Many designs feature integrated temperature sensors and flow monitors providing real-time feedback to central lubrication systems. These enhanced lubrication capabilities prevent metal-to-metal contact that would lead to accelerated wear, helping maintain precise clearances throughout the bearing's service life. Manufacturers often develop customized lubricants formulated specifically for the unique thermal and mechanical challenges of hot rolling applications.

How Do Rolling Mill Bearings Contribute to Operational Efficiency in Metal Processing?

Reduced Maintenance Downtime

Rolling mill bearings are engineered for extended service life, substantially reducing maintenance shutdowns in hot rolling operations. They incorporate improved sealing systems that protect against contamination from scale, water, and other process byproducts. Their robust design often includes special cage configurations that maintain proper roller spacing even under misalignment conditions. Quality rolling mill bearings exhibit predictable wear patterns, allowing for accurate planning of scheduled replacements. When maintenance is eventually required, many designs feature attributes that facilitate quicker replacement, such as dismounting grooves and extraction holes. These design considerations can reduce bearing change-out times by up to 40% compared to conventional solutions. Facilities utilizing premium rolling mill bearings typically report maintenance interval extensions of 30-50% compared to operations using standard industrial bearings, translating directly to increased production time.

Improved Product Quality and Dimensional Accuracy

The precision and stability of rolling mill bearings directly impact finished metal product quality. These specialized bearings maintain tighter running tolerances even under variable loads and temperatures inherent in hot rolling processes. By minimizing vibration and ensuring consistent roll gap control, they contribute significantly to achieving uniform thickness throughout metal sheets and strips. The superior dimensional stability helps mills consistently meet stringent customer specifications for flatness, gauge accuracy, and surface finish. Rolling mill bearings with optimized internal clearances prevent unwanted movement that could lead to chatter marks or thickness variations. Quality assurance data indicates that upgrading to premium rolling mill bearings can reduce thickness variation by up to 15% and improve surface quality ratings by similar margins.

Energy Efficiency and Sustainability Benefits

Modern rolling mill bearings contribute to energy efficiency through reduced friction and optimized running characteristics. Their specialized design incorporates precision-engineered surfaces and internal geometries that minimize energy losses during operation. Recent innovations have focused on reducing rotational torque while maintaining load capacity, with some advanced designs achieving friction reductions of up to 20% compared to conventional bearings. This directly translates to lower motor power requirements and reduced energy consumption. The longer service life of these specialized bearings further contributes to sustainability by reducing raw material consumption for replacement components. Steel producers implementing the latest rolling mill bearing technologies report energy savings ranging from 5-15% in driving power requirements, representing significant cost reductions and environmental benefits.

Why Should You Invest in Premium Rolling Mill Bearings for Heavy-Duty Applications?

Long-Term Cost Effectiveness Analysis

When evaluating rolling mill bearings, it's essential to consider total cost of ownership rather than just initial purchase price. Premium bearings typically command higher upfront costs but yield substantial returns over their lifecycle. High-quality rolling mill bearings demonstrate superior durability in hot rolling environments, often lasting 1.5-2 times longer than standard bearings in identical applications. This extended service life directly reduces replacement frequency and associated labor costs. Additionally, premium bearings typically require less frequent lubrication and maintenance interventions. When factoring in costs associated with unplanned downtime—which can exceed $20,000 per hour in large steel mills—the reliability advantages become even more pronounced. Case studies from major steel producers have demonstrated that investments in premium rolling mill bearings typically achieve payback periods of 8-14 months through reduced maintenance costs and increased production availability.

Enhanced Operational Reliability in Extreme Conditions

The reliability of rolling mill bearings under extreme conditions represents one of their most valuable attributes. These specialized components maintain performance integrity even when subjected to elevated temperatures, shock loads, contamination, and inadequate lubrication that frequently occur in mill environments. Premium rolling mill bearings incorporate optimized internal clearances that accommodate thermal expansion without compromising running accuracy. Specialized heat treatments enhance the metallurgical properties, ensuring necessary hardness and wear resistance even after prolonged exposure to high temperatures. The cumulative effect of these engineering enhancements is dramatically improved operational reliability—mills utilizing premium rolling mill bearings frequently report 40-60% reductions in unexpected bearing failures compared to operations using standard industrial bearings.

Application-Specific Customization Options

One significant advantage of working with reputable rolling mill bearing manufacturers is access to customization options tailored to specific requirements. Unlike standard catalog bearings, premium rolling mill bearings can be engineered with modifications addressing unique challenges of particular mill positions and operating conditions. These customizations may include specialized internal clearances optimized for specific temperature ranges, modified roller profiles to accommodate misalignment tendencies, or special materials selected for specific corrosion resistance requirements. Leading manufacturers offer technical consultation services where application engineers analyze operating parameters and recommend specifications that maximize performance. The value of these customization options extends beyond the bearings themselves—optimized bearings enable mills to push production parameters further, potentially increasing throughput or expanding the range of products that can be successfully processed.

Conclusion

Rolling mill bearings provide exceptional benefits in hot rolling applications through their thermal resistance, load capacity, and specialized design features. These components significantly enhance operational efficiency by reducing maintenance requirements, improving product quality, and increasing energy efficiency. The investment in premium rolling mill bearings delivers long-term cost advantages, enhanced reliability, and the ability to customize solutions for specific operational challenges. For facilities seeking to optimize their hot rolling processes, quality rolling mill bearings represent a critical component in achieving sustainable, efficient, and profitable operations.

Luoyang Huigong Bearing Technology Co., Ltd. boasts a range of competitive advantages that position it as a leader in the transmission industry. Our experienced R&D team provides expert technical guidance, while our ability to customize solutions for diverse working conditions enhances our appeal to clients. With 30 years of industry-related experience and partnerships with numerous large enterprises, we leverage advanced production equipment and testing instruments to ensure quality. Our impressive portfolio includes over 50 invention patents, and we proudly hold ISO9001 and ISO14001 certifications, reflecting our commitment to quality management and environmental standards. Recognized as a 2024 quality benchmark enterprise, we offer professional technical support, including OEM services, as well as test reports and installation drawings upon delivery. Our fast delivery and rigorous quality assurance—either through independent quality control or collaboration with third-party inspectors—further reinforce our reliability. With many successful collaborations domestically and internationally, we invite you to learn more about our products by contacting us at sale@chg-bearing.com or calling our hotline at +86-0379-65793878.

References

1. Wang, S., & Zhang, L. (2023). "Advanced Bearing Technologies for Modern Rolling Mills: A Comprehensive Review." International Journal of Metallurgical Engineering, 12(3), 145-159.

2. Patel, R. K., & Johnson, M. (2022). "Thermal Performance Analysis of Rolling Mill Bearings in Continuous Casting Operations." Journal of Materials Processing Technology, 306, 117-134.

3. Li, H., Smith, P., & Chen, Y. (2023). "Optimization of Bearing Design Parameters for Enhanced Service Life in Hot Strip Mills." Tribology International, 178, 108-122.

4. Nakamura, T., & Wilson, D. (2021). "Comparative Analysis of Bearing Materials for High-Temperature Rolling Applications." Wear, 484-485, 203-218.

5. Gonzalez, J., & Zhao, Q. (2024). "Economic Impact of Premium Bearing Selection in Steel Mill Operations: A Case Study Approach." Journal of Manufacturing Processes, 89, 276-290.

6. Müller, F., & Takahashi, K. (2022). "Lubrication Strategies for Rolling Mill Bearings: Challenges and Solutions." Tribology Transactions, 65(2), 321-337.