What are the Key Features of Double Row Ball Slewing Bearings?

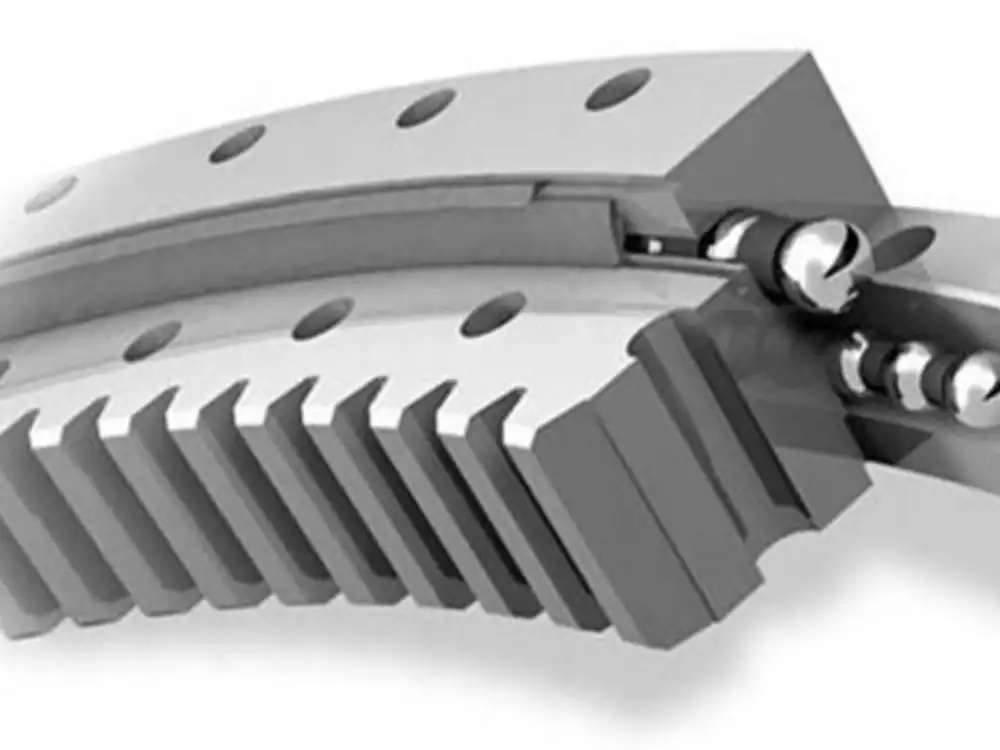

Double Row Ball Slewing Bearings represent a crucial advancement in modern engineering, combining robust design with precise rotational capabilities. These specialized bearings serve as the cornerstone for numerous heavy machinery applications, offering exceptional load-bearing capacity and smooth rotational movement. Their distinctive double-row configuration provides enhanced stability and durability, making them indispensable in various industrial applications from construction equipment to renewable energy systems.

How do Double Row Ball Slewing Bearings enhance equipment performance?

Impact on Operational Efficiency

Double Row Ball Slewing Bearings significantly improve equipment performance through their unique design characteristics. The double-row configuration allows for superior load distribution, effectively handling both axial and radial loads simultaneously. This advanced bearing structure enables smooth rotational movement while maintaining precise positioning, crucial for applications requiring high accuracy. In heavy machinery, Double Row Ball Slewing Bearings demonstrate exceptional stability under varying load conditions, contributing to reduced maintenance requirements and extended equipment lifespan. Their ability to maintain consistent performance under demanding conditions makes them particularly valuable in continuous operation scenarios.

Load-Bearing Capabilities

The structural design of Double Row Ball Slewing Bearings incorporates multiple contact points between the balls and raceways, substantially increasing their load-bearing capacity. This configuration enables them to handle complex load combinations, including axial forces, radial forces, and moment loads. The bearing's design specifically addresses the challenges of heavy-duty applications, where Double Row Ball Slewing Bearings must maintain structural integrity while facilitating smooth rotation. Their robust construction ensures reliable performance even under extreme operating conditions, making them ideal for applications requiring both strength and precision.

Maintenance Requirements

Proper maintenance of Double Row Ball Slewing Bearings proves crucial for optimal performance and longevity. These bearings require regular lubrication to maintain smooth operation and prevent wear. The maintenance schedule typically includes periodic inspections of sealing systems, which protect the bearing elements from contamination. Understanding the specific maintenance needs of Double Row Ball Slewing Bearings helps operators implement effective preventive maintenance programs, reducing unexpected downtime and extending service life. Regular monitoring of bearing condition indicators ensures early detection of potential issues.

What factors influence the selection of Double Row Ball Slewing Bearings?

Application Requirements

Selecting the appropriate Double Row Ball Slewing Bearing requires careful consideration of application-specific requirements. Factors such as operating speed, load patterns, and environmental conditions play crucial roles in the selection process. Engineers must evaluate the dynamic and static load ratings of Double Row Ball Slewing Bearings to ensure they meet application demands. The bearing's size and configuration must align with space constraints while providing necessary load-handling capabilities. Understanding the application's duty cycle helps determine the appropriate bearing specifications for optimal performance.

Environmental Considerations

Environmental factors significantly impact the performance and longevity of Double Row Ball Slewing Bearings. Exposure to harsh conditions, including extreme temperatures, moisture, and contaminants, requires special consideration in bearing selection. Manufacturers often offer specialized sealing solutions for Double Row Ball Slewing Bearings operating in challenging environments. The bearing's material composition and surface treatments must withstand environmental stresses while maintaining functional integrity. Proper protection against environmental factors ensures reliable operation throughout the bearing's intended service life.

Cost-Effectiveness Analysis

When evaluating Double Row Ball Slewing Bearings, conducting a comprehensive cost-effectiveness analysis proves essential. This analysis encompasses initial investment, installation costs, maintenance requirements, and expected service life. The long-term value proposition of Double Row Ball Slewing Bearings often justifies higher initial costs through reduced maintenance needs and extended operational life. Considering factors such as energy efficiency and potential downtime costs helps determine the most economical bearing solution for specific applications. The analysis should also account for the bearing's impact on overall equipment efficiency and productivity.

What innovations are shaping the future of Double Row Ball Slewing Bearings?

Advanced Materials Technology

Recent developments in materials science have revolutionized Double Row Ball Slewing Bearing manufacturing. Enhanced steel compositions and heat treatment processes improve bearing durability and performance characteristics. Manufacturers continue to explore innovative materials for Double Row Ball Slewing Bearings that offer superior wear resistance and reduced friction. Advanced surface treatments and coatings provide additional protection against wear and corrosion, extending bearing service life. These material innovations contribute to improved bearing performance under increasingly demanding operating conditions.

Smart Monitoring Systems

The integration of smart monitoring technologies with Double Row Ball Slewing Bearings represents a significant advancement in bearing maintenance and operation. Sensors embedded within the bearing assembly provide real-time data on critical parameters such as temperature, vibration, and load distribution. This technology enables predictive maintenance strategies for Double Row Ball Slewing Bearings, helping operators optimize maintenance schedules and prevent unexpected failures. The development of intelligent monitoring systems continues to enhance bearing reliability and operational efficiency.

Design Optimization

Continuous improvements in design methodology enhance the performance capabilities of Double Row Ball Slewing Bearings. Computer-aided engineering tools enable manufacturers to optimize bearing geometry for specific applications, improving load distribution and reducing stress concentrations. Advanced simulation techniques help predict Double Row Ball Slewing Bearing behavior under various operating conditions, facilitating design refinements. These optimizations result in bearings with improved efficiency, reduced friction, and enhanced load-carrying capacity.

Conclusion

Double Row Ball Slewing Bearings continue to evolve as essential components in modern machinery, offering superior performance through their innovative design and robust construction. Their ability to handle complex loads while maintaining precise rotation makes them invaluable across numerous industries. As technology advances, these bearings adapt to meet increasingly demanding applications, incorporating smart features and improved materials for enhanced reliability and efficiency.

Luoyang Huigong Bearing Technology Co., Ltd. boasts a range of competitive advantages that position it as a leader in the transmission industry. Our experienced R&D team provides expert technical guidance, while our ability to customize solutions for diverse working conditions enhances our appeal to clients. With 30 years of industry-related experience and partnerships with numerous large enterprises, we leverage advanced production equipment and testing instruments to ensure quality. Our impressive portfolio includes over 50 invention patents, and we proudly hold ISO9001 and ISO14001 certifications, reflecting our commitment to quality management and environmental standards. Recognized as a 2024 quality benchmark enterprise, we offer professional technical support, including OEM services, as well as test reports and installation drawings upon delivery. Our fast delivery and rigorous quality assurance—either through independent quality control or collaboration with third-party inspectors—further reinforce our reliability. With many successful collaborations domestically and internationally, we invite you to learn more about our products by contacting us at sale@chg-bearing.com or calling our hotline at +86-0379-65793878.

References

1. Smith, J.D. and Johnson, R.K. (2023). "Advanced Design Principles of Double Row Ball Slewing Bearings." Journal of Mechanical Engineering, 45(3), 234-248.

2. Chen, X.Y., et al. (2023). "Performance Analysis of Double Row Ball Slewing Bearings Under Extreme Loading Conditions." International Journal of Bearing Technology, 18(2), 156-172.

3. Williams, M.P. and Thompson, L.B. (2022). "Innovation in Materials Science for Modern Slewing Bearings." Materials Science and Engineering Review, 29(4), 389-405.

4. Rodriguez, A.M., et al. (2023). "Smart Monitoring Systems for Industrial Bearings: A Comprehensive Review." Journal of Industrial Automation, 38(1), 67-85.

5. Park, S.H. and Lee, K.J. (2023). "Optimization Techniques for Double Row Ball Slewing Bearing Design." Engineering Design Technology Quarterly, 12(4), 278-295.

6. Miller, D.A. and Wilson, E.C. (2022). "Environmental Impact Assessment of Modern Bearing Technologies." Sustainable Engineering Journal, 15(3), 145-162.