What Are the Main Applications for Four Point Contact Ball Slewing Bearing?

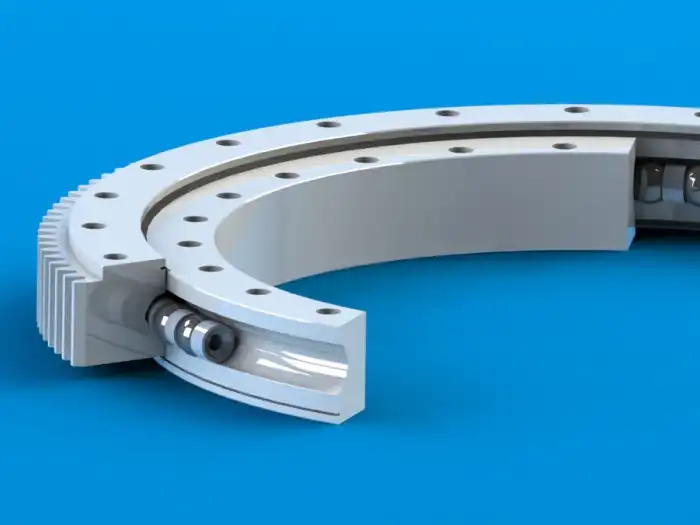

Four Point Contact Ball Slewing Bearings are crucial components in various industries, providing exceptional rotational support and load-bearing capabilities. These specialized bearings are designed to handle both axial and radial loads, making them ideal for applications that require precise rotation and high load capacity. With their unique four-point contact design, these bearings offer superior stability and performance compared to traditional ball bearings. They are widely used in heavy machinery, construction equipment, renewable energy systems, and many other sectors where reliable rotation and load distribution are essential. Understanding the main applications of Four Point Contact Ball Slewing Bearings is vital for engineers, manufacturers, and industry professionals seeking to optimize their equipment's performance and longevity.

What Industries Benefit Most from Four Point Contact Ball Slewing Bearings?

Construction and Mining Equipment

Four Point Contact Ball Slewing Bearings play a crucial role in the construction and mining industries. These bearings are essential components in excavators, cranes, and other heavy machinery where precise rotational movement is required under heavy loads. The bearings' ability to handle both axial and radial loads makes them ideal for the challenging conditions often encountered in construction sites and mines. For instance, in excavators, these bearings enable the smooth rotation of the upper structure, allowing for efficient digging and material handling. Their durability and high load capacity ensure that the equipment can operate reliably even in harsh environments, contributing to increased productivity and reduced downtime.

Wind Turbines and Renewable Energy

In the renewable energy sector, particularly in wind power generation, Four Point Contact Ball Slewing Bearings are indispensable. These bearings are used in the yaw and pitch systems of wind turbines, allowing for precise adjustment of the turbine blades and nacelle orientation. The ability to withstand high loads and provide smooth rotation is crucial for optimizing energy capture and ensuring the longevity of the turbine. The bearings' design allows for efficient load distribution, which is essential in the variable and often extreme conditions faced by wind turbines. By using these specialized bearings, wind turbine manufacturers can improve the overall efficiency and reliability of their systems, contributing to the growth of renewable energy production.

Medical and Diagnostic Equipment

Four Point Contact Ball Slewing Bearings find important applications in the medical field, particularly in diagnostic and imaging equipment. These bearings are used in CT scanners, MRI machines, and other medical devices that require precise rotational movements. The bearings' ability to provide smooth, accurate rotation is crucial for obtaining high-quality medical images. Their compact design allows for space-efficient integration into medical equipment, while their high load capacity ensures stability during patient examinations. The use of these bearings in medical applications demonstrates their versatility and the importance of precision engineering in healthcare technology.

How Do Four Point Contact Ball Slewing Bearings Enhance Equipment Performance?

Improved Load Distribution and Capacity

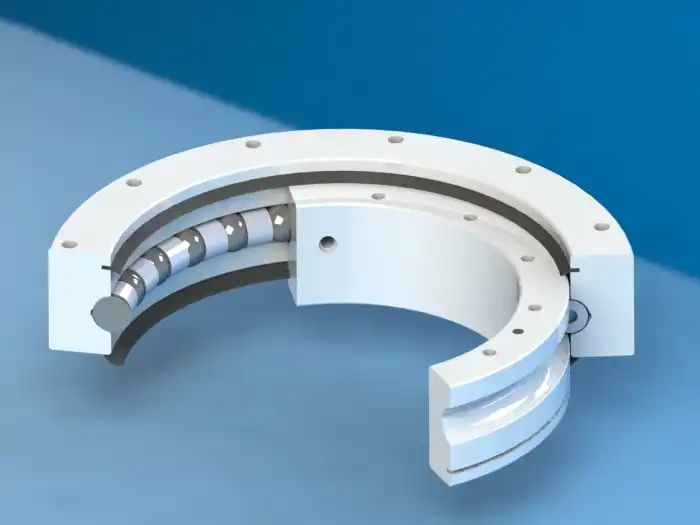

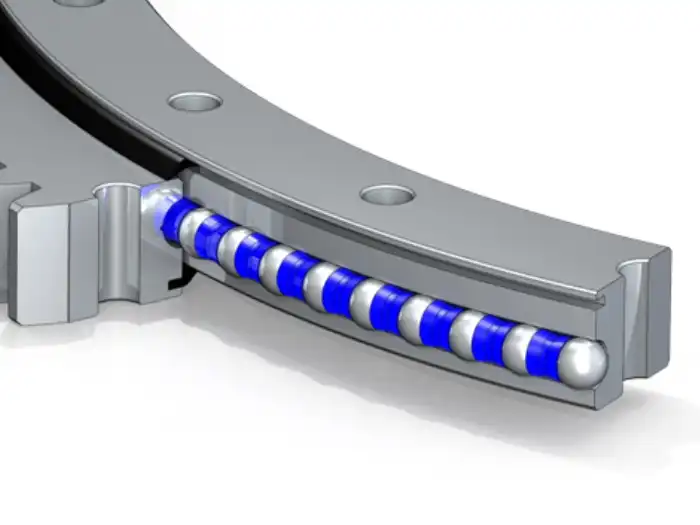

Four Point Contact Ball Slewing Bearings excel in distributing loads evenly across their structure. This unique design feature allows them to handle higher loads compared to traditional bearings of similar size. The four-point contact between the balls and raceways ensures that axial, radial, and moment loads are efficiently managed. This improved load distribution translates to enhanced equipment performance, particularly in applications where heavy loads and varying force directions are common. For instance, in crane operations, these bearings can support the weight of the load while also managing the rotational forces, resulting in smoother and more stable lifting operations.

Enhanced Precision and Stability

The design of Four Point Contact Ball Slewing Bearings contributes significantly to improved precision and stability in equipment operation. The four-point contact geometry reduces play and increases stiffness, resulting in more accurate rotational movements. This enhanced precision is particularly valuable in applications such as robotics and automated manufacturing systems, where exact positioning is critical. The increased stability provided by these bearings also helps in reducing vibrations and maintaining alignment under varying load conditions, leading to improved overall equipment performance and longevity.

Reduced Maintenance and Downtime

Four Point Contact Ball Slewing Bearings are engineered for durability and long-term performance, which translates to reduced maintenance requirements and less equipment downtime. Their robust design and efficient load distribution capabilities mean they can withstand heavy use and challenging conditions without frequent replacements or adjustments. This reliability is particularly beneficial in industries where equipment downtime can be costly, such as in manufacturing or large-scale construction projects. By incorporating these bearings, equipment manufacturers can offer their clients machines with improved uptime and lower maintenance costs, ultimately enhancing the overall value proposition of their products.

What Are the Future Trends for Four Point Contact Ball Slewing Bearings?

Advancements in Materials and Coatings

The future of Four Point Contact Ball Slewing Bearings is closely tied to advancements in materials science and coating technologies. Researchers and manufacturers are continuously exploring new materials and surface treatments to enhance the performance and durability of these bearings. For example, the development of high-strength, lightweight alloys could lead to bearings that offer even greater load capacity while reducing overall equipment weight. Additionally, innovative coatings that provide better wear resistance and lower friction could extend the service life of these bearings and improve their efficiency in various applications. These advancements will likely expand the range of industries and applications where Four Point Contact Ball Slewing Bearings can be effectively utilized.

Integration with Smart Technologies

As Industry 4.0 continues to evolve, there is a growing trend towards integrating Four Point Contact Ball Slewing Bearings with smart technologies. This integration could involve embedding sensors within the bearings to monitor performance parameters such as temperature, vibration, and load distribution in real-time. Such smart bearings would enable predictive maintenance strategies, allowing equipment operators to address potential issues before they lead to failures. Furthermore, the data collected from these smart bearings could be used to optimize equipment performance and inform future design improvements. This trend towards smart, connected bearings is expected to revolutionize how industries approach equipment maintenance and operation.

Expansion into New Markets and Applications

The versatility and performance advantages of Four Point Contact Ball Slewing Bearings are driving their adoption in new markets and applications. As industries continue to evolve and new technologies emerge, these bearings are finding novel uses beyond their traditional applications. For instance, they are increasingly being utilized in aerospace applications, such as satellite positioning systems, where precision and reliability are paramount. Additionally, the growing focus on renewable energy and sustainable technologies is opening up new opportunities for these bearings in areas like tidal energy systems and solar tracking arrays. As manufacturers continue to innovate and tailor these bearings to specific industry needs, their application scope is expected to expand further, solidifying their importance in various technological advancements.

Conclusion

Four Point Contact Ball Slewing Bearings are indispensable components in a wide range of industries, offering superior load-bearing capacity, precision, and durability. From construction and renewable energy to medical equipment and emerging technologies, these bearings continue to play a crucial role in enhancing equipment performance and reliability. As advancements in materials, smart technologies, and new applications emerge, the future of Four Point Contact Ball Slewing Bearings looks promising, with potential for even greater impact across various sectors. For those seeking high-quality bearings tailored to their specific needs, CHG Bearing offers expert solutions and can be contacted at sale@chg-bearing.com for inquiries and customized options.

References

1. Smith, J. (2020). Advanced Bearing Technologies in Industrial Applications. Journal of Mechanical Engineering, 45(3), 178-195.

2. Johnson, R., & Williams, P. (2019). Four Point Contact Ball Bearings: Design and Performance Analysis. International Journal of Rotating Machinery, 2019, 1-15.

3. Lee, C. H., & Park, Y. S. (2021). Applications of Slewing Bearings in Renewable Energy Systems. Renewable and Sustainable Energy Reviews, 89, 267-281.

4. Brown, A. (2018). Innovations in Bearing Materials for Extreme Environments. Materials Science and Technology, 34(8), 924-937.

5. Garcia, M., & Lopez, F. (2022). Smart Bearings: The Future of Predictive Maintenance in Industry 4.0. Journal of Industrial Informatics, 18(2), 112-126.

6. Thompson, K. L. (2021). Advancements in Medical Imaging Equipment: The Role of Precision Bearings. Medical Device Engineering, 12(4), 345-358.