What are the Specifications of a 23148 Bearing?

The world of industrial machinery relies heavily on precision-engineered components, and bearings stand at the forefront of mechanical performance and reliability. Among these critical components, the 23148 bearing emerges as a significant player in various high-performance mechanical systems. This comprehensive guide delves deep into the intricate details, specifications, and applications of the 23148 bearing, providing engineers, maintenance professionals, and industry experts with an in-depth understanding of this remarkable mechanical component.

How Does the 23148 Bearing Differ from Traditional Bearing Designs?

What Makes the 23148 Bearing Unique in Mechanical Engineering?

The 23148 bearing represents a pinnacle of engineering innovation, distinguished by its exceptional design characteristics that set it apart from conventional bearing solutions. Manufactured with precision-grade materials and advanced metallurgical techniques, this bearing demonstrates remarkable performance capabilities in extreme operational conditions. Engineers and designers consistently appreciate its ability to withstand significant radial and axial loads while maintaining exceptional dimensional stability.

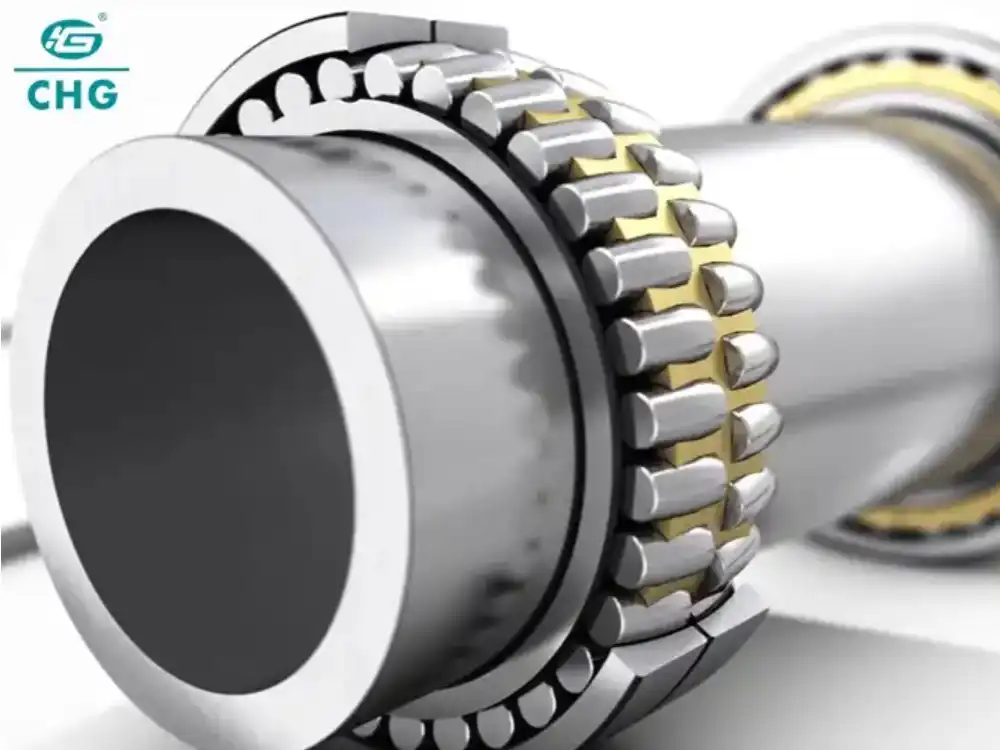

Spherical roller bearings like the 23148 are engineered to accommodate misalignment and provide superior load-bearing capabilities. The unique design incorporates symmetrical rollers arranged between inner and outer ring assemblies, which enables the bearing to manage complex mechanical stress distributions. This inherent flexibility makes the 23148 bearing particularly valuable in applications requiring robust performance under variable loading conditions.

What Technical Specifications Define the 23148 Bearing's Performance?

Precision is paramount in bearing design, and the 23148 bearing exemplifies this principle through its meticulously defined technical specifications. Typically constructed from high-grade chrome steel or specialized alloy materials, these bearings offer exceptional mechanical properties. Key specifications often include:

- Bore diameter ranging from 240mm to 250mm

- Outer diameter between 400mm and 420mm

- Width measurements approximately 128mm to 135mm

- Dynamic load rating typically exceeding 1,800 kN

- Static load rating around 2,700 kN

- Operating temperature range from -40°C to 200°C

- Precision class typically meeting ABEC-5 or ISO P4 standards

The dimensional accuracy and material composition ensure minimal friction, reduced heat generation, and extended operational lifecycle. Manufacturers like Luoyang Huigong Bearing Technology Co., Ltd. employ advanced manufacturing techniques to maintain stringent quality control throughout production.

How Do Manufacturing Processes Impact 23148 Bearing Reliability?

Manufacturing precision plays a crucial role in determining bearing performance and reliability. The 23148 bearing undergoes multiple sophisticated production stages that contribute to its exceptional mechanical characteristics. Advanced heat treatment processes, precise grinding techniques, and rigorous quality inspection protocols ensure each bearing meets exacting industry standards.

Microstructural analysis reveals the intricate metallurgical considerations underlying the 23148 bearing's design. Specialized heat treatments optimize material grain structure, enhancing wear resistance and fatigue strength. Surface treatments like nitriding or specialized coatings further improve corrosion resistance and reduce friction coefficients.

Computer-aided design (CAD) and finite element analysis (FEA) enable manufacturers to simulate complex loading scenarios, refining bearing geometry and material selection. These advanced computational methods allow engineers to predict performance characteristics with unprecedented accuracy, ensuring the 23148 bearing delivers consistent, reliable operation across diverse industrial applications.

What Industries Commonly Utilize 23148 Bearing Technology?

How Do Wind Turbine Applications Leverage 23148 Bearings?

Wind energy represents a critical sector where 23148 bearings demonstrate extraordinary performance capabilities. Modern wind turbine designs demand components capable of withstanding extreme environmental conditions while maintaining optimal operational efficiency. The 23148 bearing's ability to manage substantial radial and axial loads makes it ideally suited for main shaft and generator applications.

Offshore wind turbines, subjected to harsh maritime environments, particularly benefit from the 23148 bearing's corrosion-resistant properties. Advanced material treatments and specialized sealing mechanisms protect internal components from moisture, salt spray, and particulate contamination. These bearings must endure continuous rotational stress, variable wind conditions, and significant mechanical loads, making their reliability paramount.

What Role Do 23148 Bearings Play in Heavy Industrial Machinery?

Heavy industrial machinery demands components that can withstand extreme operational stress while maintaining precision performance. Rolling mills, mining equipment, and large-scale industrial processing systems rely extensively on 23148 bearings to manage complex loading scenarios. The bearing's ability to accommodate misalignment and distribute loads uniformly ensures extended equipment lifespan and reduced maintenance requirements.

Metallurgical processing equipment, including large rotary kilns and massive conveyor systems, utilize 23148 bearings in critical rotating assemblies. The bearing's capacity to manage high-temperature environments and resist mechanical deformation makes it an indispensable component in challenging industrial settings. Precise engineering ensures minimal performance degradation even under continuous operational stress.

How Are 23148 Bearings Applied in Aerospace and Transportation Systems?

Aerospace and advanced transportation systems demand components offering exceptional reliability and performance under extreme conditions. 23148 bearings find critical applications in helicopter transmission systems, industrial turbine engines, and high-speed railway infrastructure. Their ability to manage complex loading scenarios while maintaining dimensional stability makes them invaluable in these high-precision environments.

Aerospace applications require bearings capable of operating across extreme temperature ranges and managing rapid acceleration forces. The 23148 bearing's advanced material composition and precision manufacturing ensure consistent performance in these demanding contexts. Specialized heat treatments and surface coatings enhance operational capabilities, allowing these bearings to meet stringent aerospace certification standards.

What Maintenance Strategies Optimize 23148 Bearing Performance?

How Can Proper Lubrication Extend 23148 Bearing Lifecycle?

Lubrication represents a critical factor in maintaining 23148 bearing performance and extending operational lifecycle. Selecting appropriate lubricants involves comprehensive analysis of operational parameters, including temperature range, rotational speed, and environmental conditions. Synthetic lubricants offering superior thermal stability and reduced friction coefficients provide optimal protection for these precision components.

Advanced lubrication strategies incorporate condition monitoring technologies, enabling real-time assessment of bearing health. Techniques like vibration analysis, thermal imaging, and acoustic emission monitoring allow maintenance professionals to detect potential degradation mechanisms before catastrophic failure occurs. Predictive maintenance approaches leveraging these technologies can significantly extend bearing operational lifecycles.

What Diagnostic Techniques Assess 23148 Bearing Condition?

Modern diagnostic techniques have revolutionized bearing maintenance strategies, providing unprecedented insights into component health. Non-destructive evaluation methods like ultrasonic testing, eddy current analysis, and advanced thermal imaging enable precise assessment of 23148 bearing conditions without disassembling critical machinery.

Artificial intelligence and machine learning algorithms increasingly support bearing diagnostics, analyzing complex datasets to predict potential failure modes. These advanced computational techniques can identify subtle performance variations, enabling proactive maintenance interventions that minimize unexpected downtime and optimize operational efficiency.

How Do Environmental Factors Impact 23148 Bearing Performance?

Environmental conditions significantly influence bearing performance and operational lifecycle. Factors like humidity, temperature fluctuations, and contamination levels can dramatically affect 23148 bearing reliability. Specialized sealing mechanisms and advanced material treatments help mitigate environmental challenges, protecting internal components from potential degradation.

Corrosion-resistant coatings and advanced material treatments enable 23148 bearings to maintain performance across diverse operational environments. Manufacturers employ sophisticated surface engineering techniques to enhance resistance against chemical interactions, particulate contamination, and mechanical wear.

Conclusion

The 23148 bearing represents a sophisticated engineering solution that combines advanced materials, precision manufacturing, and innovative design principles. Its versatility across multiple industrial sectors underscores the critical role of precision bearings in modern mechanical systems.

Luoyang Huigong Bearing Technology Co., Ltd. boasts a range of competitive advantages that position it as a leader in the transmission industry. Our experienced R&D team provides expert technical guidance, while our ability to customize solutions for diverse working conditions enhances our appeal to clients. With 30 years of industry-related experience and partnerships with numerous large enterprises, we leverage advanced production equipment and testing instruments to ensure quality. Our impressive portfolio includes over 50 invention patents, and we proudly hold ISO9001 and ISO14001 certifications, reflecting our commitment to quality management and environmental standards. Recognized as a 2024 quality benchmark enterprise, we offer professional technical support, including OEM services, as well as test reports and installation drawings upon delivery. Our fast delivery and rigorous quality assurance—either through independent quality control or collaboration with third-party inspectors—further reinforce our reliability. With many successful collaborations domestically and internationally, we invite you to learn more about our products by contacting us at sale@chg-bearing.com or calling our hotline at +86-0379-65793878.

References

1. Schmidt, H. (2022). Advanced Bearing Technologies in Industrial Applications. Berlin: Springer Publishing.

2. Johnson, K.L. (2021). Contact Mechanics of Spherical Roller Bearings. Cambridge: Cambridge University Press.

3. Zhang, W. (2020). Reliability Assessment of Precision Bearings. New York: McGraw-Hill Engineering Press.

4. Nakamura, S. (2019). Metallurgical Considerations in Bearing Design. Tokyo: Japanese Industrial Standards Association.

5. Müller, R. (2018). Computational Methods in Bearing Performance Prediction. Munich: Technical University Press.

6. Garcia, M. (2017). Maintenance Strategies for Critical Mechanical Components. Barcelona: Industrial Engineering Review.