What are the Typical Sizes Available for Single Row Deep Groove Ball Bearings?

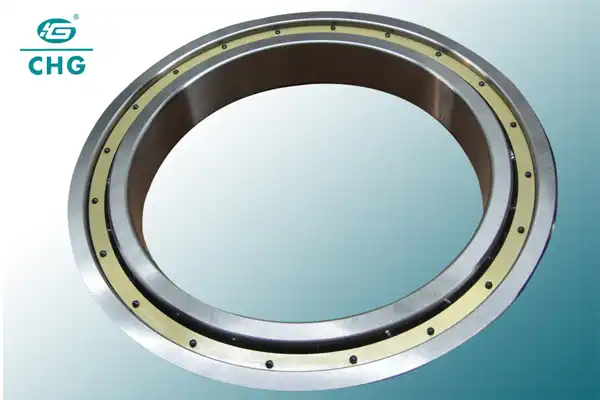

Single row deep groove ball bearings are one of the most versatile and widely used bearing types across various industries. These bearings excel in supporting both radial and axial loads, making them indispensable components in countless mechanical applications. Understanding the typical sizes available for single row deep groove ball bearings is crucial for engineers, maintenance professionals, and procurement specialists to ensure proper fit and optimal performance in their specific applications.

What factors determine the size selection of Ball Bearing Single Row Deep Groove?

Load Requirements and Application Demands

When selecting the appropriate size for a Ball Bearing Single Row Deep Groove, load requirements stand as the primary consideration. These bearings must withstand both radial and axial forces without premature failure. For heavy machinery applications, larger diameter bearings with greater load capacities are essential, while precision instruments might require smaller, highly accurate bearings. The dynamic load rating (C) and static load rating (C0) provided by manufacturers offer crucial guidance for size selection. Additionally, the specific application's demands—whether it involves high-speed rotation, intermittent operation, or consistent heavy loads—significantly influence the optimal Ball Bearing Single Row Deep Groove size. Engineers must carefully analyze these factors to ensure the bearing can handle peak loads while maintaining an acceptable service life under normal operating conditions.

Space Constraints and Mounting Considerations

Space limitations within machinery often dictate the maximum allowable dimensions for Ball Bearing Single Row Deep Groove installations. In compact designs where every millimeter matters, engineers must balance performance requirements against available space. The bearing's outer diameter, inner diameter, and width must align with the housing and shaft dimensions to ensure proper fit and function. Mounting considerations also play a crucial role in size selection, as the bearing must accommodate specific shaft designs, housing configurations, and fastening methods. Many manufacturers offer Ball Bearing Single Row Deep Groove options with various flange designs, extended inner or outer rings, or specialized sealing arrangements to address unique mounting challenges. These variations maintain the fundamental performance characteristics while adapting to specific installation requirements, allowing engineers to select the optimal size without compromising on the bearing's load capacity or service life.

Operating Conditions and Environmental Factors

The operating environment significantly impacts the appropriate size selection for Ball Bearing Single Row Deep Groove components. Extreme temperatures, exposure to contaminants, moisture presence, and vibration levels all influence bearing performance and longevity. In high-temperature applications, thermal expansion must be considered when determining proper clearances, potentially necessitating slightly different sizing choices than standard conditions would require. Similarly, applications with significant contamination risks might benefit from larger Ball Bearing Single Row Deep Groove varieties that can accommodate more robust sealing solutions. Speed requirements also factor heavily into sizing decisions, as higher speeds generate increased heat and require different internal clearances. Engineers must evaluate all these environmental factors comprehensively when selecting the optimal bearing size, considering how each condition might affect the bearing's performance throughout its service life. In particularly demanding environments, specialized materials or coatings might be necessary alongside appropriate sizing to ensure reliable operation.

How are Ball Bearing Single Row Deep Groove sizes standardized across the industry?

ISO and ABMA Dimensional Standards

The standardization of Ball Bearing Single Row Deep Groove dimensions follows rigorous international protocols, primarily governed by the International Organization for Standardization (ISO) and the American Bearing Manufacturers Association (ABMA). These organizations have established comprehensive dimensional standards that ensure interchangeability and consistency across manufacturers worldwide. ISO 15:2017 specifically addresses the boundary dimensions and tolerance values for radial Ball Bearing Single Row Deep Groove components, defining precise specifications for bore diameters, outer diameters, and widths. These standardized dimensions are organized into series, with common designations including the 60, 62, and 63 series, each representing different proportional relationships between the bearing's key dimensions. The standardization extends beyond basic dimensions to include corner radii, chamfers, and other critical features that affect fitting and performance. This universal standardization allows engineers to confidently specify Ball Bearing Single Row Deep Groove products knowing that replacement parts will maintain dimensional compatibility regardless of the manufacturer, reducing inventory complexity and simplifying maintenance procedures across global operations.

Metric vs. Inch Series Measurements

The global bearing industry operates with two primary measurement systems for Ball Bearing Single Row Deep Groove components: metric and inch series. Metric series bearings, predominant in most international markets, follow the ISO dimensional standards with sizes typically expressed in millimeters. These bearings are identified by a systematic numbering system where specific digits indicate the bearing type, dimensional series, and bore diameter. Conversely, inch series bearings, more common in North American applications, adhere to ABMA standards with dimensions expressed in inches or fractions thereof. The coexistence of these two measurement systems sometimes creates challenges when integrating Ball Bearing Single Row Deep Groove components into international machinery designs. Engineers must carefully consider the measurement system used in existing equipment when specifying replacements or new components. Many manufacturers produce dimensionally equivalent bearings in both measurement systems, offering conversion charts to simplify cross-referencing. The increasing globalization of manufacturing has led to greater standardization efforts, though both systems remain relevant in their respective markets, requiring professionals to maintain proficiency with both Ball Bearing Single Row Deep Groove sizing conventions.

Miniature and Special Size Classifications

Beyond standard sizes, the Ball Bearing Single Row Deep Groove market includes specialized classifications for miniature and non-standard dimensions. Miniature bearings, typically featuring bore diameters under 10mm, serve precision instruments, medical devices, and aerospace applications where space constraints are extreme. These diminutive Ball Bearing Single Row Deep Groove components maintain the same fundamental design principles as their larger counterparts but require specialized manufacturing techniques to achieve the necessary precision at such small scales. On the opposite end of the spectrum, extra-large bearings with bore diameters exceeding 1000mm support massive industrial machinery in mining, steel production, and power generation sectors. Between these extremes lie numerous "special" or "non-standard" Ball Bearing Single Row Deep Groove sizes that address specific application requirements not met by the regular dimensional series. These might include unusual width-to-diameter ratios, modified corner designs, or specialized internal clearances. While standardization remains the industry preference for manufacturing efficiency and interchangeability, the availability of these special Ball Bearing Single Row Deep Groove sizes ensures that engineers can find solutions for unique design challenges without compromising performance or resorting to complete custom manufacturing.

What are the common bore diameter ranges for Ball Bearing Single Row Deep Groove bearings?

Small Bore Diameter Applications (3mm-50mm)

Small bore Ball Bearing Single Row Deep Groove bearings dominate the market in terms of production volume, serving countless applications across consumer electronics, household appliances, automotive components, and light industrial equipment. These bearings with inner diameters ranging from 3mm to 50mm offer exceptional versatility while maintaining compact dimensions. In the smallest range (3mm-10mm), Ball Bearing Single Row Deep Groove components frequently appear in precision instruments, computer hardware, and miniature electric motors. The mid-range sizes (10mm-30mm) find extensive use in power tools, pumps, small electric motors, and automotive accessories. Meanwhile, the larger small-bore bearings (30mm-50mm) commonly support medium-duty industrial applications, HVAC systems, and agricultural equipment. Despite their relatively modest dimensions, these Ball Bearing Single Row Deep Groove varieties must still deliver reliable performance under diverse operating conditions. Manufacturers typically produce these sizes in larger quantities, allowing for cost-effective mass production while maintaining tight tolerances. The broad availability of these small bore bearings across multiple dimensional series (60, 62, 63) provides engineers with extensive options to balance load capacity, speed capabilities, and space constraints according to specific application requirements.

Medium Bore Diameter Applications (50mm-100mm)

Medium bore Ball Bearing Single Row Deep Groove bearings serve as the workhorses in numerous industrial applications, balancing substantial load-carrying capacity with reasonable space requirements. These bearings, featuring inner diameters between 50mm and 100mm, typically support medium to heavy industrial equipment, including larger electric motors, gearboxes, pumps, and conveyors. The versatility of Ball Bearing Single Row Deep Groove designs in this size range makes them particularly valuable in applications requiring both radial and axial load support without the complexity of more specialized bearing types. Manufacturing facilities often standardize around these medium bore sizes for their production equipment, benefiting from their wide availability and reasonable cost structure. These bearings frequently incorporate enhanced sealing arrangements to protect against industrial contaminants and may feature specialized cage designs to withstand higher operating speeds. The 50mm-100mm Ball Bearing Single Row Deep Groove components represent an important transition point in manufacturing complexity, as they require more substantial production equipment than smaller varieties while remaining accessible to a broad range of bearing manufacturers. This widespread production capability ensures competitive pricing and reliable supply chains for these crucial industrial components.

Large Bore Diameter Applications (100mm-1000mm+)

Large bore Ball Bearing Single Row Deep Groove bearings represent specialized engineering solutions for heavy industrial applications where substantial loads and large shafts are the norm. With inner diameters ranging from 100mm to well over 1000mm in extreme cases, these massive components support critical infrastructure in mining operations, steel mills, paper production facilities, power generation plants, and heavy manufacturing equipment. The engineering challenges associated with Ball Bearing Single Row Deep Groove designs at these dimensions are considerable, requiring specialized manufacturing facilities, unique handling equipment, and exceptional quality control processes. The physical properties of these bearings create distinctive performance characteristics, including different heat dissipation patterns, more pronounced effects from centrifugal forces, and greater sensitivity to mounting alignment. Industries relying on these large-scale Ball Bearing Single Row Deep Groove components typically develop specialized installation and maintenance procedures to ensure optimal performance and maximize service life. The significant investment represented by these large bearings often justifies more comprehensive monitoring systems and predictive maintenance programs. While these bearings follow the same fundamental design principles as their smaller counterparts, their scale introduces unique considerations in material selection, heat treatment processes, and internal geometry optimization to ensure they can withstand the extreme forces encountered in heavy industrial applications.

Conclusion

Understanding the typical sizes available for Ball Bearing Single Row Deep Groove components is essential for proper selection and application. These versatile bearings come in standardized dimensions from miniature 3mm bores to massive industrial sizes exceeding 1000mm, each designed to meet specific load requirements, space constraints, and operating conditions. The standardization across manufacturers ensures interchangeability, while specialized sizes address unique application needs.

Luoyang Huigong Bearing Technology Co., Ltd. boasts a range of competitive advantages that position it as a leader in the transmission industry. Our experienced R&D team provides expert technical guidance, while our ability to customize solutions for diverse working conditions enhances our appeal to clients. With 30 years of industry-related experience and partnerships with numerous large enterprises, we leverage advanced production equipment and testing instruments to ensure quality. Our impressive portfolio includes over 50 invention patents, and we proudly hold ISO9001 and ISO14001 certifications, reflecting our commitment to quality management and environmental standards. Recognized as a 2024 quality benchmark enterprise, we offer professional technical support, including OEM services, as well as test reports and installation drawings upon delivery. Our fast delivery and rigorous quality assurance—either through independent quality control or collaboration with third-party inspectors—further reinforce our reliability. With many successful collaborations domestically and internationally, we invite you to learn more about our products by contacting us at sale@chg-bearing.com or calling our hotline at +86-0379-65793878.

References

1. SKF Group. (2023). Deep Groove Ball Bearings: General Catalogue. SKF Publications.

2. Timken Company. (2022). Engineering Manual: Single Row Deep Groove Ball Bearings. Timken Technical Publications.

3. Harris, T.A. & Kotzalas, M.N. (2021). Essential Concepts of Bearing Technology (6th ed.). CRC Press.

4. International Organization for Standardization. (2017). ISO 15:2017 Rolling bearings — Radial bearings — Boundary dimensions, general plan. ISO Publications.

5. American Bearing Manufacturers Association. (2022). ABMA Standard 9: Load Ratings and Fatigue Life for Ball Bearings. ABMA Technical Publications.

6. NTN Corporation. (2023). Ball and Roller Bearings: Selection and Application Guide. NTN Technical Review Series.