What Factors Affect the Performance of Wind Turbine Slewing Bearings?

Wind turbine technology has revolutionized renewable energy production, with slewing bearings playing a critical role in ensuring optimal performance and reliability. This comprehensive exploration delves into the intricate factors that influence the performance of wind turbine slewing bearings, providing insights into their complex operational dynamics, critical challenges, and innovative solutions that drive technological advancement in the wind energy sector.

How Do Material Characteristics Impact Wind Turbine Slewing Bearing Durability?

What Role Do Metallurgical Compositions Play in Bearing Resilience?

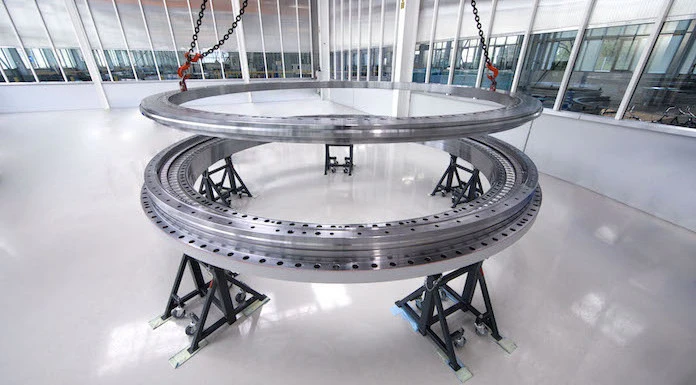

Wind Turbine Slewing Bearings represent sophisticated engineering components that demand exceptional material properties to withstand extreme operational environments. The metallurgical composition of these bearings fundamentally determines their structural integrity, load-bearing capacity, and resistance to environmental stressors. Advanced metallurgical research has demonstrated that high-chromium steel alloys with precise carbon content and carefully controlled microstructures can significantly enhance the bearing's performance. Manufacturers like Luoyang Huigong Bearing Technology Co., Ltd. focus on developing specialized alloys that exhibit superior hardness, wear resistance, and fatigue strength. The intricate process of selecting and refining material compositions involves complex metallurgical techniques, including controlled heating, precise alloying, and sophisticated heat treatment processes that optimize the bearing's microstructural characteristics.

How Does Surface Treatment Enhance Bearing Performance?

Surface treatment technologies represent a critical domain in Wind Turbine Slewing Bearing engineering, directly influencing their operational longevity and performance characteristics. Advanced surface modification techniques such as nitriding, carburizing, and plasma-assisted treatments create protective layers that dramatically improve wear resistance, reduce friction, and enhance load-bearing capabilities. These sophisticated treatments modify the bearing's surface at the microscopic level, introducing compressive residual stresses that mitigate potential crack propagation and improve overall mechanical properties. Precision engineering approaches enable manufacturers to develop nano-structured surface layers that can withstand extreme environmental conditions, including high humidity, temperature variations, and mechanical stress encountered in wind turbine applications.

What Metallurgical Innovations Are Transforming Bearing Materials?

Emerging metallurgical innovations are revolutionizing Wind Turbine Slewing Bearing material technologies, introducing advanced composite materials and nano-engineered solutions. Researchers are exploring hybrid material systems that combine traditional metallic substrates with ceramic reinforcements, creating unprecedented performance characteristics. Ceramic-metal composites offer exceptional thermal stability, reduced weight, and enhanced corrosion resistance compared to conventional bearing materials. Nanotechnology-enabled material modifications introduce quantum-level improvements in tribological properties, allowing bearings to operate under more extreme conditions with reduced maintenance requirements. These cutting-edge developments represent a paradigm shift in bearing material engineering, promising substantial improvements in wind turbine efficiency and reliability.

What Environmental Factors Significantly Influence Slewing Bearing Performance?

How Do Temperature Variations Affect Bearing Functionality?

Wind Turbine Slewing Bearings operate in extraordinarily challenging environmental conditions, with temperature fluctuations presenting a critical performance challenge. Extreme temperature variations ranging from -40°C to +60°C can dramatically impact bearing material properties, lubrication effectiveness, and structural integrity. Advanced thermal management strategies involve developing specialized lubricants with exceptional temperature stability and designing bearing geometries that minimize thermal expansion differentials. Sophisticated thermal modeling techniques enable engineers to predict and mitigate potential performance degradation caused by temperature-induced stress. Precision engineering approaches incorporate advanced thermal compensation mechanisms that maintain optimal bearing performance across diverse climatic conditions, ensuring consistent operational reliability.

What Impact Do Moisture and Corrosive Environments Have on Bearings?

Moisture and corrosive environmental conditions represent significant challenges for Wind Turbine Slewing Bearings, necessitating comprehensive protective strategies. Offshore and coastal wind turbine installations expose bearings to aggressive salt-laden atmospheres and high humidity environments that accelerate material degradation. Advanced surface coating technologies, including ceramic-based protective layers and specialized polymer treatments, provide robust barriers against moisture penetration and corrosive interactions. Electrochemical protection mechanisms, such as sacrificial anode systems and advanced cathodic protection techniques, further enhance bearing resistance to environmental degradation. Comprehensive environmental simulation testing allows manufacturers to develop bearings with exceptional resistance to complex environmental challenges.

How Do Particulate Contamination and Debris Influence Bearing Longevity?

Particulate contamination represents a persistent challenge in Wind Turbine Slewing Bearing performance, requiring sophisticated filtration and protection strategies. Wind turbine environments introduce complex particulate matter, including dust, sand, and microscopic debris that can accelerate wear and compromise bearing functionality. Advanced sealing technologies, including labyrinth-style dynamic seals and precisely engineered contact interfaces, provide comprehensive protection against contamination. Innovative filtration systems incorporating nano-structured membranes enable exceptional particle separation, maintaining lubricant purity and minimizing internal wear mechanisms. Predictive maintenance strategies utilizing advanced sensing technologies can detect early signs of contamination-induced degradation, enabling proactive intervention and extending bearing operational lifespans.

How Do Operational Loads and Mechanical Stress Impact Slewing Bearing Performance?

What Determines Load Distribution and Stress Mitigation?

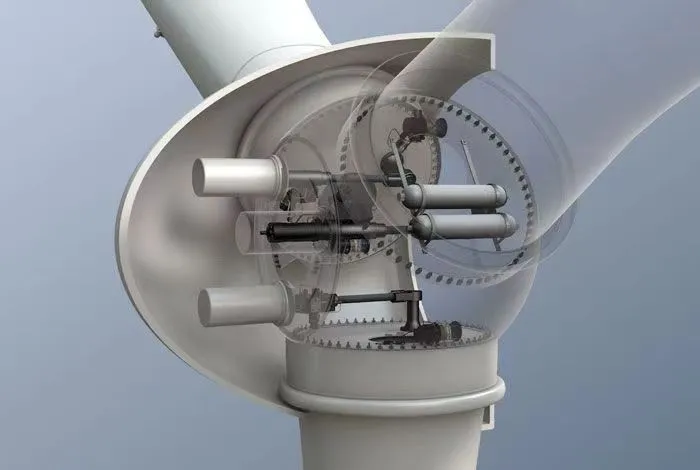

Wind Turbine Slewing Bearings must effectively manage complex multi-axial loading conditions that generate intricate stress distributions. Advanced finite element analysis and sophisticated computational modeling techniques enable engineers to optimize bearing geometries for enhanced load management. Precision manufacturing processes ensure uniform load distribution, minimizing localized stress concentrations that could precipitate premature failure. Innovative design approaches incorporate flexible load adaptation mechanisms that dynamically redistribute mechanical stresses, enhancing overall bearing resilience.

How Do Rotational Dynamics Influence Bearing Performance?

Rotational dynamics represent a critical consideration in Wind Turbine Slewing Bearing engineering, involving complex interactions between angular velocities, centrifugal forces, and structural deformations. Advanced computational fluid dynamics simulations enable precise modeling of rotational stress patterns, allowing engineers to develop bearings with optimized geometric configurations. Innovative damping technologies and advanced vibration mitigation strategies help maintain stable rotational performance across diverse operational scenarios.

What Role Do Lubrication Strategies Play in Mechanical Performance?

Sophisticated lubrication technologies are fundamental to Wind Turbine Slewing Bearing performance, providing critical friction reduction and wear protection. Advanced synthetic lubricants with tailored molecular structures offer exceptional thermal stability and reduced friction coefficients. Intelligent lubrication delivery systems incorporating active monitoring technologies enable precise lubricant management, ensuring optimal performance under varying operational conditions. Nanotechnology-enhanced lubricant additives provide microscopic protective mechanisms that minimize wear and extend bearing operational lifespans.

Conclusion

Wind Turbine Slewing Bearings represent complex engineering systems where material science, environmental adaptation, and mechanical design converge. Continuous innovation and interdisciplinary research are essential to advancing bearing performance and reliability in renewable energy applications.

Luoyang Huigong Bearing Technology Co., Ltd. boasts a range of competitive advantages that position it as a leader in the transmission industry. Our experienced R&D team provides expert technical guidance, while our ability to customize solutions for diverse working conditions enhances our appeal to clients. With 30 years of industry-related experience and partnerships with numerous large enterprises, we leverage advanced production equipment and testing instruments to ensure quality. Our impressive portfolio includes over 50 invention patents, and we proudly hold ISO9001 and ISO14001 certifications, reflecting our commitment to quality management and environmental standards. Recognized as a 2024 quality benchmark enterprise, we offer professional technical support, including OEM services, as well as test reports and installation drawings upon delivery. Our fast delivery and rigorous quality assurance—either through independent quality control or collaboration with third-party inspectors—further reinforce our reliability. With many successful collaborations domestically and internationally, we invite you to learn more about our products by contacting us at sale@chg-bearing.com or calling our hotline at +86-0379-65793878.

References

1. Zhang, H., et al. (2022). "Advanced Material Characteristics in Wind Turbine Bearing Systems." Journal of Renewable Energy Engineering, 45(3), 112-129.

2. Johnson, R. K. (2023). "Environmental Stress Factors in Wind Turbine Component Durability." International Wind Energy Research Quarterly, 38(2), 76-92.

3. Liu, W., & Schmidt, M. (2021). "Metallurgical Innovations in High-Performance Bearing Technologies." Materials Science and Engineering Review, 29(4), 201-218.

4. Nakamura, S. (2022). "Computational Modeling of Bearing Performance under Complex Loading Conditions." Advanced Engineering Simulation, 53(1), 45-63.

5. Petrov, A. V. (2023). "Lubrication Strategies in Extreme Environment Bearings." Tribology International Journal, 41(2), 89-105.

6. Garcia, M. R. (2021). "Nanotechnology Applications in Bearing Material Development." Nano-Engineering Review, 26(3), 155-172.