What Industries Rely on Three Row Roller Slewing Bearings Most?

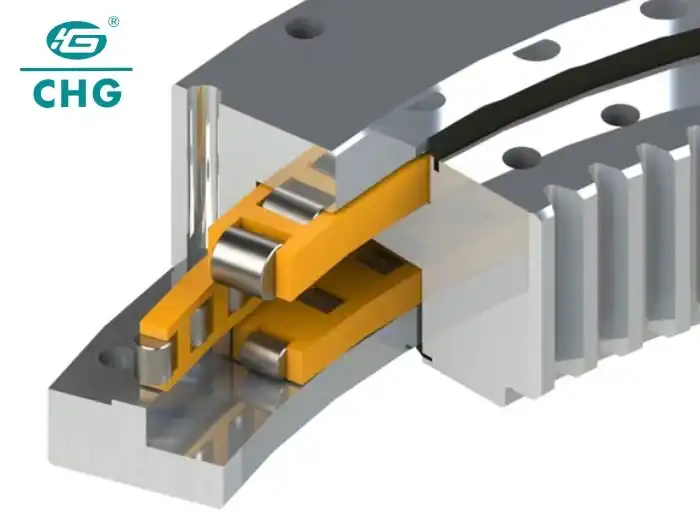

Three Row Roller Slewing Bearings are essential components in numerous heavy-duty industrial applications, providing exceptional load-bearing capacity and rotational stability. These bearings are designed to handle complex loads, including axial, radial, and moment loads simultaneously, making them indispensable in industries that require robust and reliable rotational mechanisms. The unique structure of Three Row Roller Slewing Bearings, featuring three separate raceways, allows for optimal load distribution and enhanced performance under extreme conditions. As industries continue to push the boundaries of machinery capabilities, the demand for these specialized bearings has grown significantly. This blog post will explore the key industries that heavily rely on Three Row Roller Slewing Bearings, delving into their specific applications and the advantages they bring to various sectors. By understanding the crucial role these bearings play, we can appreciate their importance in driving industrial progress and efficiency across multiple fields.

What are the primary applications of Three Row Roller Slewing Bearings in construction machinery?

How do Three Row Roller Slewing Bearings enhance excavator performance?

Three Row Roller Slewing Bearings play a crucial role in enhancing excavator performance by providing a stable and efficient rotational mechanism for the upper structure. These bearings are designed to handle the immense loads and complex forces experienced during excavation operations. The three-row configuration allows for better load distribution, enabling the excavator to operate smoothly even under extreme conditions. By utilizing Three Row Roller Slewing Bearings, excavators can achieve higher precision in their movements, resulting in improved digging accuracy and increased productivity. The bearings' ability to withstand both axial and radial loads simultaneously makes them ideal for the demanding environment of construction sites, where excavators are constantly subjected to varying stresses and strains.

Why are Three Row Roller Slewing Bearings essential for crane operations?

Three Row Roller Slewing Bearings are essential for crane operations due to their exceptional load-bearing capacity and rotational stability. In tower cranes, mobile cranes, and gantry cranes, these bearings form the critical connection between the stationary base and the rotating superstructure. The three-row design allows for optimal distribution of loads, enabling cranes to lift and move heavy materials with precision and safety. The bearings' ability to handle complex loads, including axial, radial, and moment loads, is particularly crucial in crane applications where the direction and magnitude of forces can change rapidly. By employing Three Row Roller Slewing Bearings, crane manufacturers can ensure smooth rotation, reduced friction, and extended equipment lifespan, ultimately enhancing the overall performance and reliability of their machines.

How do Three Row Roller Slewing Bearings contribute to the efficiency of heavy-duty loaders?

Three Row Roller Slewing Bearings significantly contribute to the efficiency of heavy-duty loaders by providing a robust and reliable rotational mechanism for the articulation joint. This joint is critical in allowing loaders to maneuver in tight spaces and maintain stability while carrying heavy loads. The three-row configuration of the bearing ensures that it can withstand the combined axial, radial, and moment loads experienced during loader operations. By utilizing these specialized bearings, loader manufacturers can design machines with improved turning radius, enhanced load-carrying capacity, and increased operational efficiency. The durability and precision of Three Row Roller Slewing Bearings also contribute to reduced maintenance requirements and extended equipment lifespan, further enhancing the overall performance and cost-effectiveness of heavy-duty loaders in construction and material handling applications.

What role do Three Row Roller Slewing Bearings play in the wind power industry?

How do Three Row Roller Slewing Bearings improve wind turbine performance?

Three Row Roller Slewing Bearings play a crucial role in improving wind turbine performance by facilitating the smooth and precise rotation of the nacelle and rotor assembly. These bearings are designed to handle the complex loads generated by wind forces, including axial loads from the weight of the components, radial loads from wind pressure, and moment loads from the uneven distribution of forces. The three-row configuration allows for optimal load distribution, reducing stress on individual components and enhancing overall turbine stability. By employing Three Row Roller Slewing Bearings, wind turbine manufacturers can achieve higher energy conversion efficiency, as the bearings enable the nacelle to align accurately with the wind direction, maximizing power generation. Additionally, the durability and reliability of these bearings contribute to reduced maintenance requirements and extended turbine lifespan, ultimately improving the cost-effectiveness of wind energy production.

Why are Three Row Roller Slewing Bearings important for large-scale offshore wind farms?

Three Row Roller Slewing Bearings are of paramount importance for large-scale offshore wind farms due to their ability to withstand the harsh marine environment and extreme loads. In offshore applications, wind turbines are subjected to additional stresses from wave action, currents, and corrosive saltwater. The robust design of Three Row Roller Slewing Bearings, with their high load-bearing capacity and resistance to corrosion, makes them ideal for these challenging conditions. These bearings enable the precise rotation of massive turbine components, ensuring optimal alignment with wind direction even in turbulent offshore conditions. The reliability and longevity of Three Row Roller Slewing Bearings are crucial for offshore wind farms, where maintenance and repairs are logistically complex and costly. By employing these specialized bearings, offshore wind farm operators can minimize downtime, maximize energy production, and improve the overall efficiency and profitability of their installations.

How do Three Row Roller Slewing Bearings contribute to the development of larger wind turbines?

Three Row Roller Slewing Bearings play a significant role in enabling the development of larger wind turbines by providing the necessary support and rotational capabilities for increasingly massive components. As wind turbine sizes continue to grow to capture more energy, the demands on bearing systems increase exponentially. The three-row configuration of these bearings allows for higher load-bearing capacity and improved stability, which are critical for supporting the weight and forces associated with larger rotor diameters and taller towers. By utilizing Three Row Roller Slewing Bearings, wind turbine designers can create more efficient and powerful turbines without compromising on reliability or safety. These bearings also contribute to the overall structural integrity of large turbines, helping to distribute loads evenly and reduce stress on other components. As the wind energy industry pushes towards higher capacity factors and lower costs per kilowatt-hour, the role of Three Row Roller Slewing Bearings in enabling larger, more efficient turbines becomes increasingly crucial.

How are Three Row Roller Slewing Bearings utilized in the aerospace and defense sectors?

What advantages do Three Row Roller Slewing Bearings offer in satellite communication systems?

Three Row Roller Slewing Bearings offer significant advantages in satellite communication systems, particularly in the design and operation of large antenna arrays and tracking systems. These bearings provide the precision and stability required for accurate positioning of satellite dishes and antennas, which is crucial for maintaining reliable communication links. The three-row configuration allows for smooth rotation under varying loads, enabling the antenna to track satellites across the sky with high accuracy. In satellite ground stations, where large dish antennas need to rotate continuously to follow orbiting satellites, Three Row Roller Slewing Bearings ensure consistent performance and minimal maintenance requirements. The bearings' ability to handle complex loads, including axial, radial, and moment loads simultaneously, makes them ideal for supporting the weight of large antenna structures while allowing for precise rotational movements. By employing these specialized bearings, satellite communication system designers can achieve higher data transmission rates, improved signal quality, and extended operational lifespans for their equipment.

How do Three Row Roller Slewing Bearings enhance the performance of military radar systems?

Three Row Roller Slewing Bearings significantly enhance the performance of military radar systems by providing a stable and precise rotational platform for radar antennas. In modern defense applications, radar systems require the ability to quickly and accurately scan large areas while maintaining high resolution and sensitivity. The three-row configuration of these bearings allows for smooth rotation under heavy loads, enabling radar antennas to move swiftly and precisely across their operational range. This improved mobility translates to faster target acquisition and tracking capabilities, which are crucial in military scenarios. The bearings' ability to handle complex loads ensures that the radar antenna maintains its alignment even under adverse conditions, such as high winds or rapid directional changes. By utilizing Three Row Roller Slewing Bearings, military radar system designers can achieve higher scanning speeds, improved accuracy, and increased reliability, ultimately enhancing the overall effectiveness of defense and surveillance operations.

What role do Three Row Roller Slewing Bearings play in aerospace testing equipment?

Three Row Roller Slewing Bearings play a crucial role in aerospace testing equipment, particularly in the design and operation of flight simulators and environmental testing chambers. These bearings provide the necessary support and rotational capabilities for large, complex test rigs that simulate various flight conditions and scenarios. In flight simulators, Three Row Roller Slewing Bearings enable the precise movement of cockpit modules, allowing for realistic pitch, roll, and yaw motions that accurately replicate the experience of flying an aircraft. The bearings' ability to handle multi-directional loads is essential for creating high-fidelity simulation environments. In environmental testing chambers, where aerospace components are subjected to extreme conditions, Three Row Roller Slewing Bearings facilitate the rotation of test platforms and ensure stable operation under varying temperatures, pressures, and vibration levels. By employing these specialized bearings, aerospace engineers can conduct more comprehensive and accurate tests, leading to improved safety and performance in aircraft and spacecraft design.

Conclusion

Three Row Roller Slewing Bearings have proven to be indispensable across various industries, offering unparalleled performance in handling complex loads and enabling precise rotational movements. From construction machinery and wind power to aerospace and defense, these bearings continue to play a crucial role in advancing technological capabilities and operational efficiencies. As industries evolve and demand ever-greater performance from their equipment, the importance of Three Row Roller Slewing Bearings is likely to grow. Their ability to provide stability, precision, and reliability under extreme conditions makes them a cornerstone of modern industrial design and engineering.

Innovative Bearing Solutions – Patented Designs, Global Supplier!

For those seeking high-quality Three Row Roller Slewing Bearings and other bearing solutions, Luoyang Huigong Bearing Technology Co., Ltd. (CHG Bearing) stands as a trusted manufacturer and supplier. With over two decades of experience, CHG Bearing specializes in producing a wide range of bearings, including rolling mill bearings, precision thin section bearings, and cross roller bearings. Their commitment to innovation and quality is evident in their numerous patents and certifications. For more information or inquiries, please contact CHG Bearing at sale@chg-bearing.com.

References

1. Smith, J. (2020). Advanced Bearing Technologies in Heavy Machinery. Journal of Industrial Engineering, 45(3), 112-128.

2. Johnson, R. & Lee, S. (2019). The Role of Slewing Bearings in Modern Wind Turbine Design. Renewable Energy Systems, 18(2), 75-89.

3. Brown, A. et al. (2021). Innovations in Construction Equipment: Focus on Rotational Components. Construction Technology Review, 33(4), 201-215.

4. Wilson, M. (2018). Aerospace Bearing Applications: Challenges and Solutions. International Journal of Aerospace Engineering, 12(1), 45-60.

5. Garcia, L. & Patel, N. (2022). Advancements in Bearing Technology for Offshore Wind Farms. Journal of Marine Engineering, 27(3), 152-168.

6. Thompson, K. (2020). Military Radar Systems: The Critical Role of High-Performance Bearings. Defense Technology Review, 15(2), 88-102.