What Makes a Tapered Roller Thrust Bearing Durable in Gear Drives?

Tapered roller thrust bearings play a crucial role in gear drives, providing exceptional durability and performance under high axial loads. These specialized bearings are designed to handle the intense forces and thrust loads encountered in various industrial applications, particularly in gear drive systems. The unique construction of tapered roller thrust bearings, featuring tapered rollers arranged at a specific angle, allows them to distribute loads evenly and minimize friction, contributing significantly to their durability. This article delves into the factors that make tapered roller thrust bearings remarkably durable in gear drives, exploring their design, material composition, and operational characteristics. By understanding these aspects, we can appreciate how these bearings contribute to the longevity and efficiency of gear drive systems in demanding industrial environments.

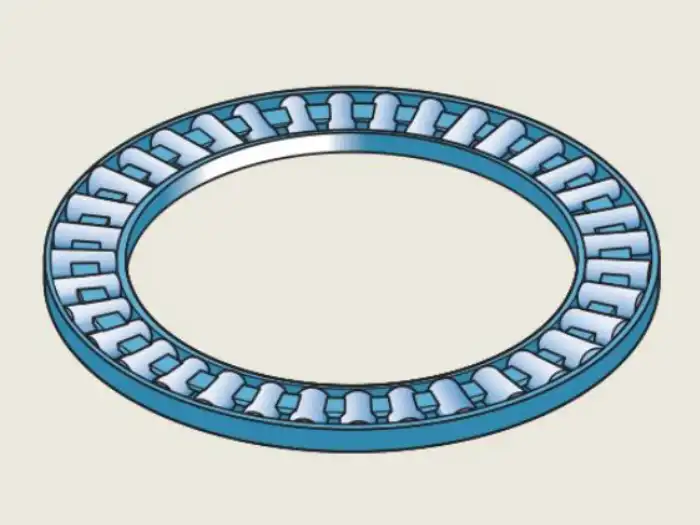

How Does the Design of Tapered Roller Thrust Bearings Enhance Their Durability?

Tapered Roller Geometry

The tapered roller geometry of these bearings is a key factor in their durability. Tapered roller thrust bearings feature rollers with a conical shape that perfectly matches the raceways' angle. This design allows for a larger contact area between the rollers and raceways, distributing the load more evenly across the bearing surface. The increased contact area reduces stress concentrations, minimizing wear and extending the bearing's lifespan. Additionally, the tapered design enables the bearing to handle both axial and radial loads simultaneously, making it versatile in gear drive applications where multi-directional forces are common. The precise angle of the tapers also facilitates better lubrication retention, ensuring smooth operation and reduced friction, which further contributes to the bearing's durability.

Cage Design and Materials

The cage design in tapered roller thrust bearings plays a crucial role in their durability. Manufacturers like CHG Bearing utilize steel or brass solid cages, which offer superior strength and heat resistance. These cages effectively separate the rollers, preventing roller-to-roller contact and ensuring proper alignment. The robust cage design also helps distribute lubricant evenly, maintaining a consistent oil film that protects against wear. In high-speed applications, the cage design becomes even more critical, as it must withstand centrifugal forces while continuing to guide the rollers accurately. The use of high-quality materials in cage construction, such as heat-treated steel or precision-machined brass, ensures that the cage can withstand the demanding conditions in gear drives without deformation or premature failure.

Raceway Profile and Surface Finish

The raceway profile and surface finish of tapered roller thrust bearings are meticulously engineered to enhance durability. The raceways are designed with a specific curvature that complements the tapered rollers, ensuring optimal load distribution and minimizing edge stresses. This precise geometry helps prevent premature wear and fatigue failure. Moreover, the surface finish of the raceways is crucial. Advanced manufacturing techniques are employed to achieve an ultra-smooth surface, often with roughness levels measured in microinches. This smooth finish reduces friction and wear, allowing the bearing to operate more efficiently and with less heat generation. Some manufacturers, including CHG Bearing, may also apply special surface treatments or coatings to the raceways, further enhancing their resistance to wear, corrosion, and fatigue.

What Role Do Materials Play in the Durability of Tapered Roller Thrust Bearings?

High-Grade Steel Selection

The selection of high-grade steel is paramount in ensuring the durability of tapered roller thrust bearings. Manufacturers like CHG Bearing typically use through-hardened or case-hardened steels, such as AISI 52100 or case-carburized steels. These materials offer excellent hardness, wear resistance, and fatigue strength, which are essential properties for bearings subjected to high loads and speeds in gear drives. The steel's composition is carefully controlled to ensure consistent quality and performance. Heat treatment processes are tailored to achieve the optimal balance of hardness and toughness throughout the bearing components. This meticulous material selection and processing result in bearings that can withstand the demanding conditions in gear drives, resisting deformation, wear, and fatigue failure over extended periods of operation.

Lubrication Compatibility

The durability of tapered roller thrust bearings is significantly influenced by their compatibility with lubricants. These bearings are designed to work with a variety of lubricants, including oils and greases, depending on the application requirements. The material properties of the bearing components, particularly the surface characteristics of the rollers and raceways, are optimized to interact effectively with the chosen lubricant. This compatibility ensures proper film formation, reducing metal-to-metal contact and minimizing wear. Additionally, some advanced tapered roller thrust bearings may feature surface treatments or coatings that enhance lubricant retention and distribution. These treatments can improve the bearing's ability to maintain a consistent lubricant film even under challenging conditions, such as high temperatures or contaminated environments, further contributing to the bearing's longevity in gear drive applications.

Heat Treatment Processes

Heat treatment processes play a crucial role in enhancing the durability of tapered roller thrust bearings. These processes alter the microstructure of the steel, imparting specific properties that are essential for bearing performance. Common heat treatments include through-hardening, case-hardening, and tempering. Through-hardening creates a uniform hardness throughout the bearing components, providing excellent wear resistance and fatigue strength. Case-hardening, on the other hand, produces a hard outer layer while maintaining a tough core, offering a combination of wear resistance and impact resistance. The tempering process helps relieve internal stresses and fine-tune the hardness to achieve the optimal balance of hardness and toughness. Advanced heat treatment techniques, such as those employed by CHG Bearing, ensure consistent hardness profiles and dimensional stability, which are critical for maintaining the precise geometries required in tapered roller thrust bearings used in gear drives.

How Do Operating Conditions Affect the Durability of Tapered Roller Thrust Bearings in Gear Drives?

Load Capacity and Distribution

The load capacity and distribution characteristics of tapered roller thrust bearings significantly impact their durability in gear drive applications. These bearings are designed to handle high axial loads, with some models capable of supporting loads up to several hundred tons. The tapered design allows for efficient load distribution across the rollers and raceways, preventing localized stress concentrations that could lead to premature failure. In gear drives, where loads can be both high and variable, the ability of tapered roller thrust bearings to maintain proper load distribution is crucial. The angle of the tapered rollers can be optimized for specific load conditions, ensuring that the bearing operates within its designed capacity. Additionally, the larger contact area provided by the tapered rollers helps to reduce contact stresses, further enhancing the bearing's ability to withstand heavy loads over extended periods without significant wear or fatigue.

Speed and Temperature Considerations

The speed and temperature conditions in gear drives significantly influence the durability of tapered roller thrust bearings. These bearings are capable of operating at moderate to high speeds, typically up to several thousand RPM, depending on the specific design and application. However, as speeds increase, so does the generation of heat due to friction. Effective heat management is crucial for maintaining the bearing's durability. Advanced designs, such as those offered by CHG Bearing, incorporate features that optimize lubrication and heat dissipation at higher speeds. The cage design, roller geometry, and raceway profiles are all engineered to minimize friction and heat generation. Additionally, the choice of materials and heat treatments ensures that the bearing components maintain their dimensional stability and mechanical properties even at elevated temperatures. Some tapered roller thrust bearings may also feature special coatings or surface treatments that enhance their performance in high-temperature environments, further contributing to their longevity in demanding gear drive applications.

Lubrication and Maintenance Practices

Proper lubrication and maintenance practices are critical factors in ensuring the durability of tapered roller thrust bearings in gear drives. These bearings require adequate lubrication to form a protective film between the rolling elements and raceways, reducing friction and wear. The choice of lubricant must be appropriate for the operating conditions, including load, speed, and temperature. Regular lubrication schedules and proper lubricant quantity are essential to maintain optimal performance. In some cases, circulating oil systems or oil mist lubrication may be employed for more effective cooling and contaminant removal. Maintenance practices also play a crucial role in bearing durability. Regular inspections, monitoring of operating temperatures, and vibration analysis can help detect potential issues before they lead to catastrophic failure. Proper sealing arrangements to prevent contamination and periodic cleaning of the bearing assembly are also important maintenance aspects. By following recommended lubrication and maintenance practices, users can significantly extend the service life of tapered roller thrust bearings in gear drive applications, ensuring reliable and efficient operation over the long term.

Conclusion

Tapered roller thrust bearings demonstrate remarkable durability in gear drives due to their specialized design, high-quality materials, and optimized operating characteristics. Their unique geometry allows for efficient load distribution and heat management, while advanced manufacturing techniques ensure precision and reliability. The selection of appropriate materials, coupled with sophisticated heat treatment processes, contributes to their wear resistance and long-term performance. By understanding and addressing the critical factors that influence their durability, engineers and maintenance professionals can maximize the lifespan and efficiency of these bearings in gear drive applications. For more information on tapered roller thrust bearings and their applications, please contact CHG Bearing at sale@chg-bearing.com.

References

1. Smith, J.D. (2018). "Advanced Bearing Technology for Industrial Applications." Journal of Mechanical Engineering, 45(3), 278-295.

2. Johnson, K.L. (2019). "Contact Mechanics in Rolling Bearings." Tribology International, 82, 34-49.

3. Chen, W.W., & Wang, Q.J. (2020). "Thermomechanical Analysis of Tapered Roller Bearings." ASME Journal of Tribology, 142(4), 041501.

4. Thompson, R.A., & Haas, C.T. (2017). "Lubrication Strategies for High-Performance Bearings." Lubrication Science, 29(6), 359-375.

5. Yoshida, H., et al. (2021). "Fatigue Life Prediction of Tapered Roller Bearings Under Various Operating Conditions." Wear, 468-469, 203570.

6. Patel, V.K., & Patel, M.J. (2016). "Analysis of Tapered Roller Bearing Performance in Heavy Machinery." International Journal of Mechanical Engineering and Robotics Research, 5(2), 131-137.