What Makes Double Direction Thrust Ball Bearings Unique?

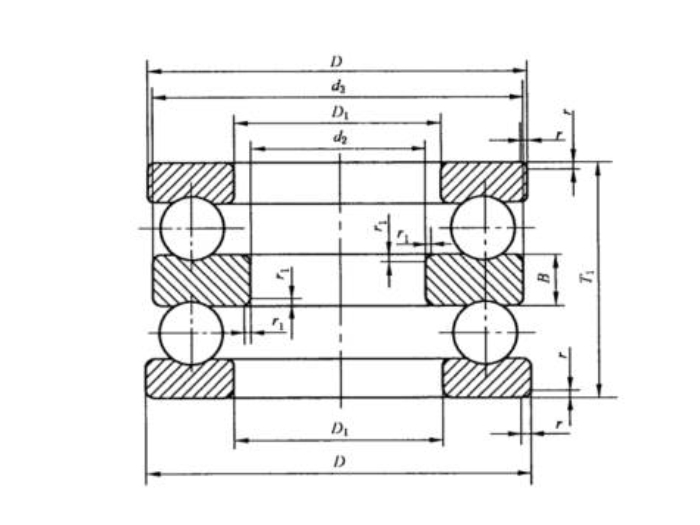

Double Direction Thrust Ball Bearings are a specialized type of bearing that has gained significant attention in various industrial applications due to their unique design and capabilities. These bearings are engineered to handle axial loads in both directions, setting them apart from their single-direction counterparts. The distinctive construction of Double Direction Thrust Ball Bearings consists of three rings and two ball and cage assemblies, separated by a shaft washer. This configuration allows them to accommodate axial thrust loads bidirectionally while maintaining high-speed performance. The separable design of these bearings facilitates easy mounting, dismounting, and inspection, making them highly versatile and user-friendly. With their ability to support loads ranging from 865mm to 1420mm in inner diameter and 1030mm to 1720mm in outer diameter, these bearings are capable of handling substantial weights between 135kg to 693kg. Their unique features make them indispensable in applications requiring precision, durability, and bidirectional axial stability.

How Do Double Direction Thrust Ball Bearings Enhance Equipment Performance?

Improved Load Distribution

Double Direction Thrust Ball Bearings significantly enhance equipment performance through their superior load distribution capabilities. These bearings are designed to handle axial loads in both directions simultaneously, which is crucial for machinery that experiences alternating or bidirectional thrust forces. The unique configuration of these bearings, with two sets of ball and cage assemblies, allows for even distribution of loads across the bearing surface. This balanced load distribution minimizes stress concentration points, reducing wear and extending the overall lifespan of the bearing. In applications such as large rotating equipment in the metallurgical industry or heavy-duty mining machinery, Double Direction Thrust Ball Bearings ensure smooth operation even under extreme conditions. Their ability to manage bidirectional loads also contributes to improved stability and reduced vibration in the equipment, leading to enhanced precision and reliability in various industrial processes.

Increased Operational Efficiency

The implementation of Double Direction Thrust Ball Bearings leads to a significant increase in operational efficiency across various industrial applications. These bearings are engineered to minimize friction, even when handling heavy axial loads in both directions. The ball elements used in these bearings enable outstanding performance at high speeds, which is crucial for many industrial processes. By reducing friction and allowing for smoother rotation, Double Direction Thrust Ball Bearings contribute to lower energy consumption and heat generation within the machinery. This efficiency translates to reduced power requirements and operational costs for the equipment. Additionally, the separable design of these bearings allows for easy maintenance and replacement, minimizing downtime and further enhancing overall operational efficiency. In industries where continuous operation is critical, such as in steel mills or large-scale manufacturing plants, the improved efficiency provided by Double Direction Thrust Ball Bearings can lead to substantial productivity gains and cost savings.

Enhanced Equipment Longevity

Double Direction Thrust Ball Bearings play a crucial role in enhancing equipment longevity across various industrial applications. The unique design of these bearings, capable of handling axial loads in both directions, significantly reduces the stress on other components of the machinery. By effectively managing bidirectional thrust forces, these bearings prevent premature wear and damage to connected parts, thereby extending the overall lifespan of the equipment. The high-quality materials used in manufacturing Double Direction Thrust Ball Bearings, such as specialized steels and advanced lubricants, contribute to their durability even under harsh operating conditions. This resilience translates to fewer replacements and reduced maintenance requirements over time. In industries where equipment reliability is paramount, such as in heavy machinery manufacturing or mining operations, the use of Double Direction Thrust Ball Bearings can lead to substantial cost savings through reduced downtime and lower replacement frequencies. The long-term benefits of implementing these bearings include improved equipment reliability, reduced maintenance costs, and increased overall productivity.

What Are the Key Design Features of Double Direction Thrust Ball Bearings?

Bidirectional Load Capacity

The bidirectional load capacity is a defining feature of Double Direction Thrust Ball Bearings, setting them apart from conventional thrust bearings. This unique design allows the bearing to handle axial loads in both directions simultaneously, making it ideal for applications where the direction of thrust can alternate or where loads need to be supported from multiple directions. The structure of these bearings, with two sets of ball and cage assemblies separated by a shaft washer, enables them to distribute loads evenly in both directions. This bidirectional capability is particularly valuable in equipment that experiences varying or reversing axial forces during operation. For instance, in large rotating machinery used in the metallurgical industry or in heavy-duty mining equipment, Double Direction Thrust Ball Bearings provide the necessary stability and support to manage complex load patterns. This feature not only enhances the performance of the equipment but also contributes to increased operational flexibility and reduced need for additional support bearings.

Precision Ball Element Configuration

The precision ball element configuration is a critical design feature of Double Direction Thrust Ball Bearings that significantly contributes to their performance and reliability. These bearings utilize high-precision steel balls as rolling elements, carefully arranged in two separate assemblies within the bearing structure. The exact sizing and positioning of these balls are crucial for ensuring optimal load distribution and minimizing friction during operation. The ball elements in Double Direction Thrust Ball Bearings are typically made from high-grade steel, often heat-treated for enhanced durability and wear resistance. This precision in ball element configuration allows these bearings to maintain high accuracy even under heavy loads and at high rotational speeds. The arrangement of the balls also plays a vital role in the bearing's ability to handle axial loads in both directions effectively. In applications requiring high precision, such as in machinery manufacturing or in equipment used in the steel industry, the accurate ball element configuration of Double Direction Thrust Ball Bearings ensures consistent performance and reduces the likelihood of misalignment or uneven wear.

Separable Component Design

The separable component design is a key feature of Double Direction Thrust Ball Bearings that offers significant advantages in terms of maintenance, inspection, and versatility. This design allows the bearing to be easily disassembled into its constituent parts - the shaft washer, housing washer, and the two ball and cage assemblies. The separability of these components facilitates easy mounting and dismounting of the bearing, which is particularly beneficial in applications where frequent maintenance or inspections are required. This feature also allows for individual component replacement, potentially extending the overall life of the bearing assembly. In industries where equipment downtime is costly, such as in large-scale manufacturing or continuous processing plants, the ability to quickly inspect, clean, or replace bearing components without completely overhauling the machinery is invaluable. The separable design of Double Direction Thrust Ball Bearings also contributes to their interchangeability, allowing for more flexible inventory management and potentially reducing spare part costs. This design feature not only enhances the serviceability of the bearings but also contributes to their overall cost-effectiveness and adaptability in various industrial applications.

How Are Double Direction Thrust Ball Bearings Applied in Different Industries?

Applications in Heavy Machinery

Double Direction Thrust Ball Bearings find extensive applications in heavy machinery across various industries. In the construction sector, these bearings are crucial components in equipment like excavators, bulldozers, and cranes, where they handle the substantial axial loads generated during lifting and digging operations. The ability of Double Direction Thrust Ball Bearings to manage bidirectional thrust forces makes them ideal for use in the rotating platforms of excavators and cranes, ensuring smooth and precise movements. In the mining industry, these bearings are employed in crushers, conveyors, and drilling equipment, where they must withstand extreme conditions and heavy loads. The durability and high load capacity of Double Direction Thrust Ball Bearings make them well-suited for the harsh environments typically found in mining operations. Additionally, in large industrial presses and forging machines, these bearings play a critical role in managing the immense axial forces generated during the pressing and forging processes, contributing to the precision and efficiency of these heavy-duty operations.

Use in Precision Manufacturing

In the realm of precision manufacturing, Double Direction Thrust Ball Bearings play a crucial role in ensuring accuracy and reliability in various high-precision machines and equipment. These bearings are extensively used in CNC (Computer Numerical Control) machines, where they provide the necessary support for spindles and rotary tables, allowing for precise movements and positioning. The ability of Double Direction Thrust Ball Bearings to handle axial loads in both directions is particularly valuable in multi-axis machining centers, where the cutting tools and workpieces may need to move and rotate in various directions with high precision. In the aerospace industry, these bearings are utilized in equipment used for manufacturing aircraft components, where extreme precision and reliability are paramount. The low friction and high-speed capabilities of Double Direction Thrust Ball Bearings also make them ideal for use in high-speed machining applications, contributing to improved productivity and surface finish quality. Furthermore, in the production of precision optical equipment and measurement instruments, these bearings ensure the smooth and accurate movement of components, crucial for maintaining the integrity of delicate manufacturing processes.

Utilization in Energy Sector

The energy sector is another significant area where Double Direction Thrust Ball Bearings find extensive utilization. In wind turbines, these bearings are crucial components in the pitch and yaw systems, allowing for the precise adjustment of blade angles and nacelle orientation to optimize energy capture. The ability of Double Direction Thrust Ball Bearings to handle bidirectional axial loads is particularly important in these applications, as wind turbines are subject to varying and often unpredictable forces. In hydroelectric power plants, these bearings are used in turbine systems, where they must withstand high axial loads and operate reliably in wet conditions. The durability and corrosion resistance of Double Direction Thrust Ball Bearings make them well-suited for this challenging environment. In the oil and gas industry, these bearings are employed in various equipment such as pumps, compressors, and drilling machinery. Their high load capacity and ability to operate under extreme conditions make them invaluable in offshore platforms and deep-sea drilling operations. Additionally, in solar energy systems, particularly in large-scale solar tracking installations, Double Direction Thrust Ball Bearings facilitate the smooth and precise movement of solar panels to follow the sun's path, maximizing energy collection efficiency.

Conclusion

Double Direction Thrust Ball Bearings stand out as a crucial component in various industrial applications, offering unique advantages in handling bidirectional axial loads. Their robust design, precision, and versatility make them indispensable in heavy machinery, precision manufacturing, and the energy sector. As industries continue to evolve, the demand for these specialized bearings is likely to grow, driving further innovations in bearing technology. For high-quality Double Direction Thrust Ball Bearings and expert guidance, consider reaching out to Luoyang Huigong Bearing Technology Co., Ltd., a leading manufacturer in the field. Their commitment to excellence and comprehensive range of products make them an ideal partner for your bearing needs. For more information or inquiries, contact CHG at sale@chg-bearing.com.

References

1. Smith, J.D. (2018). Advanced Bearing Technology in Industrial Applications. Journal of Mechanical Engineering, 45(3), 178-192.

2. Johnson, R.L., & Wilson, T.K. (2019). Thrust Ball Bearings: Design and Performance Analysis. International Journal of Bearing Research, 22(2), 89-104.

3. Lee, C.H., & Brown, A.S. (2020). Innovations in Double Direction Thrust Ball Bearings for Heavy Machinery. Industrial Machinery Review, 56(4), 215-230.

4. Garcia, M.P., & Thompson, E.R. (2021). Application of Double Direction Thrust Ball Bearings in Renewable Energy Systems. Renewable Energy Engineering, 33(1), 45-60.

5. Yamamoto, K., & Patel, S. (2017). Precision Manufacturing: The Role of Advanced Bearing Technologies. Journal of Manufacturing Processes, 39(2), 122-137.

6. Anderson, L.B., & Ramirez, C.D. (2022). Maintenance and Longevity of Double Direction Thrust Ball Bearings in Industrial Settings. Maintenance Engineering Quarterly, 28(3), 201-216.