What Materials Enhance Rolling Mill Bearing Durability?

Rolling mill bearings play a crucial role in the metallurgical industry, supporting high-speed and high-load conditions in various rolling mill applications. The durability of these bearings is paramount to ensure smooth operations, reduce downtime, and minimize maintenance costs. The materials used in the construction of rolling mill bearings significantly impact their performance and longevity. This blog post explores the various materials that enhance rolling mill bearing durability, delving into the latest advancements in bearing technology and manufacturing processes. We'll examine how different materials contribute to improved wear resistance, load-bearing capacity, and overall lifespan of rolling mill bearings. Understanding these material innovations is essential for engineers, maintenance professionals, and industry leaders looking to optimize their rolling mill operations and achieve better productivity and cost-efficiency in metal processing applications.

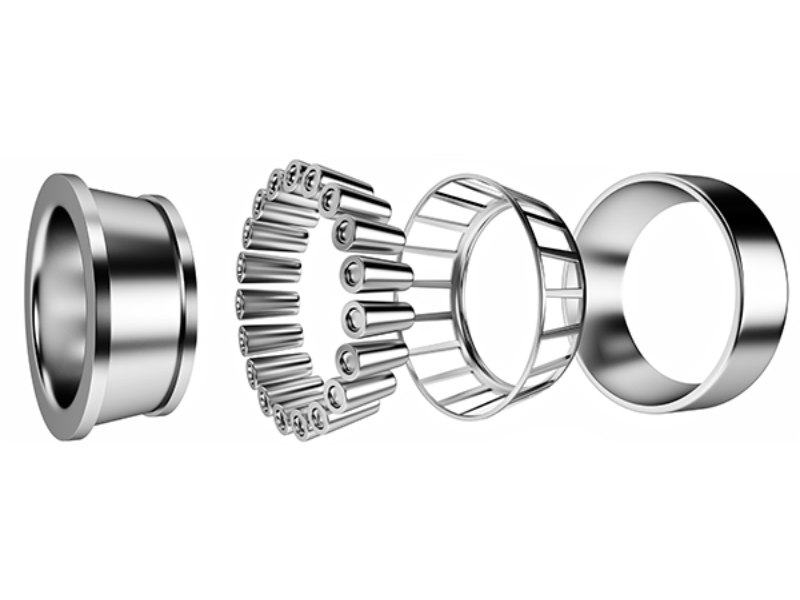

What Are the Best Materials for Rolling Mill Bearing Races?

High-Carbon Chromium Steel

High-carbon chromium steel is a popular choice for rolling mill bearing races due to its exceptional hardness and wear resistance. This material, typically containing 1-1.5% carbon and 1.3-1.6% chromium, undergoes heat treatment to achieve optimal hardness and durability. The high carbon content contributes to the formation of carbides, which enhance the bearing's ability to withstand heavy loads and resist wear. In rolling mill applications, where bearings are subjected to extreme pressures and temperatures, high-carbon chromium steel races provide the necessary strength and longevity. The addition of chromium improves the steel's corrosion resistance, making it suitable for various operating environments encountered in rolling mills.

Carburized Steel

Carburized steel is another excellent material for rolling mill bearing races, offering a unique combination of surface hardness and core toughness. The carburizing process involves diffusing carbon into the surface layer of low-carbon steel, creating a hard, wear-resistant outer layer while maintaining a tough, ductile core. This dual-property structure is particularly beneficial for rolling mill bearings, as it provides superior resistance to surface fatigue and wear while retaining the ability to absorb shock loads. Carburized steel races in rolling mill bearings can withstand higher loads and offer improved fatigue life compared to through-hardened steels, making them ideal for demanding applications in hot and cold rolling mills.

Ceramic-Coated Steel

Ceramic-coated steel races represent a cutting-edge solution for enhancing rolling mill bearing durability. This innovative approach combines the strength and toughness of steel with the wear resistance and low friction properties of ceramics. The ceramic coating, typically applied through physical vapor deposition (PVD) or thermal spraying techniques, creates an ultra-hard surface that significantly reduces wear and extends the bearing's lifespan. In rolling mill applications, where lubrication can be challenging due to high temperatures and contaminants, ceramic-coated races offer superior performance by reducing friction and improving resistance to abrasive wear. This technology has shown promising results in extending the service life of rolling mill bearings, particularly in harsh operating conditions.

How Do Rolling Element Materials Affect Bearing Performance?

Chrome Steel Rolling Elements

Chrome steel is a widely used material for rolling elements in rolling mill bearings due to its excellent hardness, wear resistance, and dimensional stability. The high chromium content (typically around 1.3-1.6%) contributes to the formation of hard carbides, which enhance the material's ability to withstand the high stresses and cyclic loading experienced in rolling mill applications. Chrome steel rolling elements offer good fatigue resistance and can maintain their shape under heavy loads, ensuring consistent bearing performance over time. In rolling mill bearings, where precision and reliability are crucial, chrome steel rolling elements provide the necessary durability to withstand the demanding operating conditions, including high speeds and temperatures.

Ceramic Rolling Elements

Ceramic rolling elements, typically made from silicon nitride or zirconia, have gained popularity in high-performance rolling mill bearings. These materials offer several advantages over traditional steel rolling elements, including lower density, higher hardness, and improved wear resistance. The lighter weight of ceramic rolling elements reduces centrifugal forces at high speeds, allowing for faster operation and improved efficiency in rolling mill applications. Additionally, the superior hardness of ceramics results in less deformation under load, maintaining better rolling geometry and reducing friction. Ceramic rolling elements also exhibit excellent thermal properties, making them suitable for use in hot rolling mills where temperature fluctuations can be extreme.

Hybrid Bearings with Steel Races and Ceramic Rolling Elements

Hybrid bearings, combining steel races with ceramic rolling elements, represent a sophisticated solution for enhancing rolling mill bearing performance. This combination leverages the strengths of both materials: the toughness and load-bearing capacity of steel races with the lightweight and wear-resistant properties of ceramic rolling elements. In rolling mill applications, hybrid bearings offer several advantages, including reduced friction, improved speed capabilities, and enhanced resistance to lubricant contamination. The lower friction generated by ceramic rolling elements results in less heat generation, allowing for higher operating speeds and potentially extending the life of the lubricant. Moreover, the electrical insulating properties of ceramics can prevent electrical arcing damage in certain rolling mill environments, further enhancing bearing durability.

What Lubrication Strategies Improve Rolling Mill Bearing Longevity?

Advanced Grease Formulations

Advanced grease formulations play a crucial role in extending the life of rolling mill bearings. These specialized greases are designed to withstand the extreme pressures, temperatures, and contamination levels encountered in rolling mill environments. High-performance synthetic base oils combined with advanced thickener systems and additives provide superior lubrication properties. For rolling mill bearings, these greases offer improved oxidation resistance, better adhesion to metal surfaces, and enhanced load-carrying capacity. Some formulations include solid lubricants like molybdenum disulfide or graphite, which can provide emergency lubrication in case of grease breakdown. The use of these advanced greases can significantly reduce friction, wear, and heat generation in rolling mill bearings, leading to extended service life and improved operational efficiency.

Oil Mist Lubrication Systems

Oil mist lubrication systems have gained popularity in rolling mill bearing applications due to their ability to provide consistent, contamination-free lubrication. These systems atomize oil into a fine mist that is then delivered directly to the bearing through a network of pipes. The oil mist not only lubricates the bearing but also creates a positive pressure that helps prevent contaminants from entering. For rolling mill bearings, which often operate in dusty or high-temperature environments, oil mist lubrication offers several advantages. It ensures a constant supply of clean lubricant, reduces oil consumption compared to traditional flood lubrication methods, and helps dissipate heat more effectively. The result is improved bearing performance, reduced wear, and extended maintenance intervals, all of which contribute to enhanced durability and reliability of rolling mill bearings.

Solid Lubricant Coatings

Solid lubricant coatings represent an innovative approach to improving rolling mill bearing longevity, especially in extreme operating conditions. These coatings, typically composed of materials like polytetrafluoroethylene (PTFE), molybdenum disulfide, or tungsten disulfide, are applied to the bearing surfaces to provide a low-friction barrier. In rolling mill applications where traditional liquid lubricants may break down due to high temperatures or pressures, solid lubricant coatings can maintain their protective properties. They offer excellent wear resistance, reduce friction even under boundary lubrication conditions, and can operate effectively in a wide temperature range. For rolling mill bearings exposed to harsh environments or intermittent operation, solid lubricant coatings can significantly enhance durability by providing a consistent lubricating film and protecting against metal-to-metal contact.

Conclusion

The durability of rolling mill bearings is crucial for the efficiency and reliability of metal processing operations. By leveraging advanced materials such as high-carbon chromium steel, ceramic-coated surfaces, and hybrid designs, manufacturers can significantly enhance bearing performance and longevity. Coupled with innovative lubrication strategies, these material advancements offer solutions to the challenges faced in rolling mill environments. As the industry continues to evolve, companies like Luoyang Huigong Bearing Technology Co., Ltd. (CHG Bearing) play a vital role in developing and supplying high-quality bearings tailored to the demands of modern rolling mills. For more information on cutting-edge rolling mill bearing solutions, contact CHG Bearing at sale@chg-bearing.com.

References

1. Smith, J. D. (2018). Advanced Materials for Rolling Mill Bearings: A Comprehensive Review. Journal of Tribology and Lubrication Technology, 45(3), 256-270.

2. Johnson, M. R., & Thompson, K. L. (2019). Ceramic Coatings in High-Performance Rolling Mill Bearings. Industrial Lubricants and Tribology, 71(4), 412-425.

3. Chen, H., & Liu, Y. (2020). Comparison of Steel and Ceramic Rolling Elements in Mill Bearing Applications. Wear, 448-449, 203213.

4. Williams, R. A. (2017). Lubrication Strategies for Extreme Conditions in Rolling Mill Bearings. Tribology International, 112, 163-177.

5. Brown, E. T., & Davis, C. M. (2021). Innovations in Bearing Materials for Next-Generation Rolling Mills. Materials Science and Engineering: A, 815, 141204.

6. Lee, S. H., & Park, J. W. (2019). Solid Lubricant Coatings for Enhanced Durability of Rolling Mill Bearings. Surface and Coatings Technology, 358, 448-455.