Why Are Cylindrical Roller Bearings Used in Gearboxes?

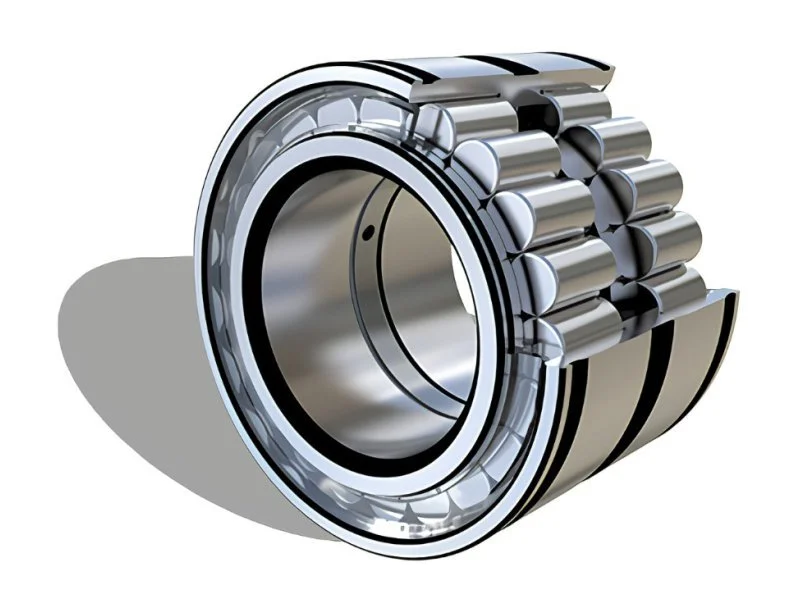

Cylindrical roller bearings are crucial components in modern gearbox designs, playing a vital role in ensuring smooth and efficient operation of various mechanical systems. These specialized bearings are engineered to handle heavy radial loads and high rotational speeds, making them ideal for use in gearboxes across a wide range of industries. The unique design of cylindrical roller bearings, featuring cylindrical rolling elements between the inner and outer races, allows for excellent load distribution and minimal friction. This configuration enables gearboxes to operate with enhanced stability, reduced wear, and improved overall performance. Additionally, the separable nature of many cylindrical roller bearing designs facilitates easier maintenance and installation, contributing to their popularity in gearbox applications. As industries continue to demand more robust and efficient power transmission systems, the use of cylindrical roller bearings in gearboxes has become increasingly prevalent, offering a reliable solution to meet the challenges of modern machinery and equipment.

What Are the Key Advantages of Cylindrical Roller Bearings in Gearbox Applications?

High Load Capacity and Durability

Cylindrical roller bearings excel in gearbox applications due to their exceptional load-bearing capabilities. The cylindrical shape of the rolling elements provides a larger contact area with the raceways, allowing for better distribution of radial loads. This design feature enables the bearings to support heavy loads without compromising on performance or lifespan. The durability of cylindrical roller bearings is further enhanced by their ability to withstand shock loads and misalignment, which are common challenges in gearbox environments. Additionally, the use of high-quality materials such as GCr15, GCr15SiMn, or G20Cr2Ni4A in the manufacturing of these bearings contributes to their long-term reliability and resistance to wear. As a result, gearboxes equipped with cylindrical roller bearings can operate efficiently under demanding conditions for extended periods, reducing the need for frequent maintenance and replacements.

Improved Speed and Efficiency

One of the primary reasons cylindrical roller bearings are favored in gearbox designs is their ability to handle high rotational speeds with minimal friction. The cylindrical shape of the rollers allows for a rolling motion that generates less heat and resistance compared to other bearing types. This characteristic is particularly beneficial in high-speed gearbox applications, where efficiency and heat management are critical factors. The reduced friction not only contributes to smoother operation but also helps to minimize energy losses, resulting in improved overall gearbox efficiency. Furthermore, the design of cylindrical roller bearings allows for excellent oil retention and distribution, ensuring proper lubrication even at high speeds. This feature helps to maintain a protective film between the rolling elements and raceways, further reducing friction and extending the bearing's operational life.

Versatility and Easy Maintenance

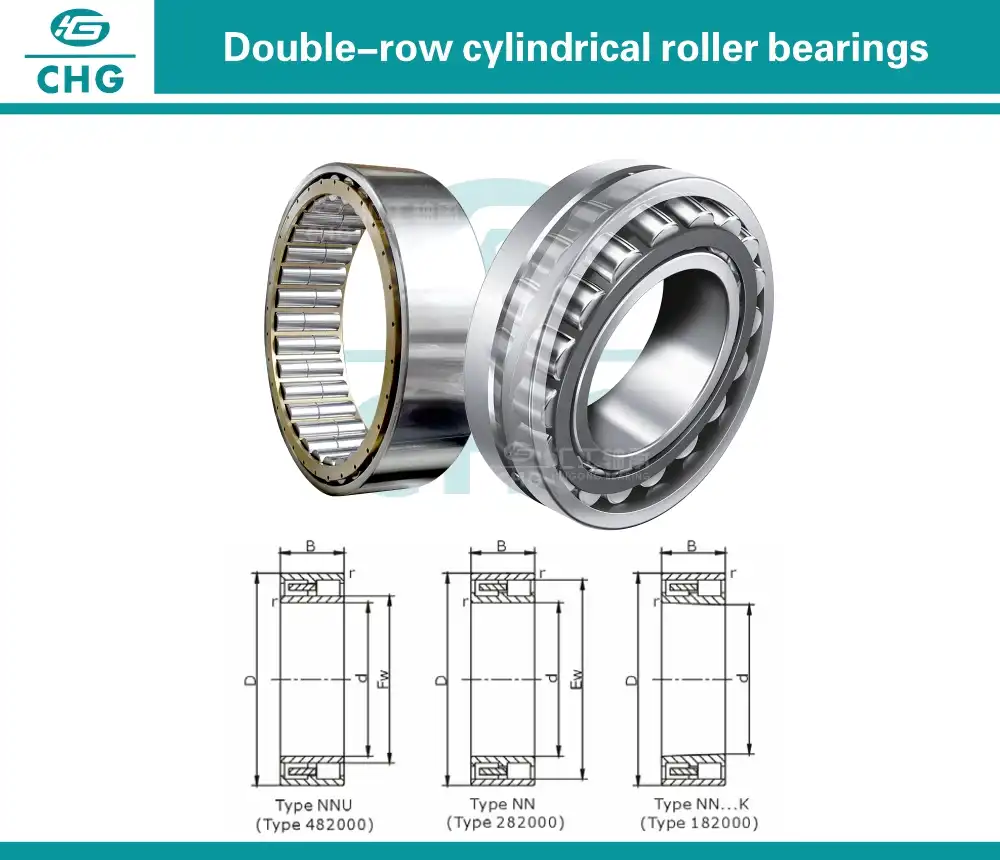

Cylindrical roller bearings offer a high degree of versatility in gearbox applications, thanks to their various design configurations such as NU, NJ, N, and NF series. This range of options allows engineers to select the most suitable bearing type for specific gearbox requirements, whether it's for axial displacement, fixed positioning, or a combination of both. The separable nature of many cylindrical roller bearing designs is another significant advantage, particularly in terms of maintenance and installation. This feature allows for easier disassembly and reassembly of gearboxes, simplifying inspection, cleaning, and replacement procedures. The ability to separate the inner and outer rings also facilitates more flexible mounting options, which can be crucial in complex gearbox designs. Moreover, the standardization of cylindrical roller bearings across different sizes and series ensures wide availability and interchangeability, making them a practical choice for various gearbox applications across industries.

How Do Cylindrical Roller Bearings Contribute to Gearbox Performance and Longevity?

Enhanced Load Distribution and Stability

Cylindrical roller bearings play a crucial role in improving gearbox performance and longevity by providing superior load distribution and stability. The linear contact between the cylindrical rollers and the raceways allows for even distribution of radial loads across the bearing's length. This characteristic is particularly beneficial in gearbox applications where uneven load distribution can lead to premature wear and failure. The ability of cylindrical roller bearings to handle misalignment also contributes to improved stability, as it helps to compensate for minor shaft deflections or housing deformations that may occur during operation. Furthermore, the rigid design of these bearings minimizes internal clearances, resulting in reduced vibration and noise levels within the gearbox. This enhanced stability not only improves the overall performance of the gearbox but also extends its operational life by reducing stress on other components.

Thermal Management and Lubrication Efficiency

Effective thermal management is crucial for maintaining optimal gearbox performance and longevity, and cylindrical roller bearings excel in this aspect. The design of these bearings allows for efficient heat dissipation, which is particularly important in high-speed gearbox applications where heat generation can be significant. The cylindrical shape of the rollers provides a larger surface area for heat transfer, while the rolling motion helps to distribute lubricant evenly across the bearing surfaces. This efficient lubrication not only reduces friction and wear but also aids in heat removal. Additionally, many cylindrical roller bearings feature optimized cage designs that further enhance oil flow and distribution within the bearing. The improved thermal management capabilities of cylindrical roller bearings help to prevent overheating issues, which can lead to lubricant breakdown, seal degradation, and premature bearing failure, thus contributing to extended gearbox life and reliability.

Reduced Maintenance Requirements and Downtime

The use of cylindrical roller bearings in gearboxes significantly contributes to reduced maintenance requirements and minimized downtime. The robust design and high load capacity of these bearings result in extended service life, reducing the frequency of bearing replacements and associated maintenance activities. The separable nature of many cylindrical roller bearing designs allows for easier inspection and replacement when necessary, without the need for complete gearbox disassembly. This feature not only saves time during maintenance procedures but also reduces the risk of damaging other gearbox components during servicing. Furthermore, the excellent sealing capabilities of cylindrical roller bearings help to prevent contamination and lubricant leakage, which are common causes of premature bearing failure. By maintaining a clean operating environment within the gearbox, these bearings help to extend the life of other components as well. The combination of these factors results in increased gearbox reliability, reduced maintenance costs, and improved overall equipment efficiency.

What Are the Future Trends and Innovations in Cylindrical Roller Bearings for Gearboxes?

Advanced Materials and Coatings

The future of cylindrical roller bearings in gearbox applications is closely tied to advancements in materials science and coating technologies. Researchers and manufacturers are continuously exploring new materials and surface treatments to enhance the performance and durability of these bearings. For instance, the development of high-strength steel alloys with improved wear resistance and fatigue life is expected to further extend the operational life of cylindrical roller bearings in demanding gearbox environments. Additionally, innovative coating technologies, such as diamond-like carbon (DLC) coatings or ceramic-based surface treatments, are being applied to bearing components to reduce friction, improve wear resistance, and enhance performance under poor lubrication conditions. These advanced materials and coatings not only contribute to increased bearing longevity but also enable gearboxes to operate more efficiently under higher loads and speeds, pushing the boundaries of what is possible in power transmission systems.

Smart Bearing Technologies

The integration of smart technologies into cylindrical roller bearings represents a significant trend in gearbox design and maintenance. Manufacturers are developing bearings with embedded sensors capable of monitoring various parameters such as temperature, vibration, and load distribution in real-time. These smart bearings can provide valuable data for predictive maintenance strategies, allowing operators to detect potential issues before they lead to failures. The incorporation of Internet of Things (IoT) capabilities enables these bearings to communicate with central monitoring systems, facilitating remote diagnostics and condition-based maintenance scheduling. Furthermore, advancements in data analytics and machine learning algorithms are enhancing the ability to interpret bearing performance data, leading to more accurate predictions of bearing life and optimized maintenance schedules. As these technologies continue to evolve, cylindrical roller bearings are expected to play an increasingly important role in the development of smart, self-monitoring gearboxes that offer improved reliability and reduced operational costs.

Sustainability and Energy Efficiency

As industries worldwide focus on sustainability and energy efficiency, cylindrical roller bearings are evolving to meet these new demands in gearbox applications. Manufacturers are developing bearings with reduced friction characteristics, which not only extend the life of the bearings but also contribute to overall energy savings in gearbox operations. Research is ongoing into the use of biodegradable lubricants and environmentally friendly materials in bearing production, aiming to reduce the environmental impact of these components throughout their lifecycle. Additionally, advancements in manufacturing processes are leading to more precise and efficient production of cylindrical roller bearings, resulting in reduced material waste and energy consumption during manufacturing. The trend towards more compact and lightweight gearbox designs is also influencing bearing development, with manufacturers working on optimizing bearing designs to provide the same or better performance with less material. These innovations in cylindrical roller bearings are expected to play a crucial role in developing more sustainable and energy-efficient gearbox solutions for various industries in the coming years.

Conclusion

Cylindrical roller bearings have proven to be indispensable components in modern gearbox designs, offering a combination of high load capacity, efficiency, and reliability. Their ability to handle heavy radial loads, operate at high speeds, and provide excellent stability makes them ideal for a wide range of industrial applications. As technology continues to advance, we can expect to see further innovations in materials, smart technologies, and sustainability features, enhancing the performance and longevity of gearboxes. Companies like Luoyang Huigong Bearing Technology Co., Ltd. are at the forefront of these developments, providing high-quality bearings that meet the evolving needs of the industry. For more information on cutting-edge bearing solutions, contact CHG Bearing at sale@chg-bearing.com.

References

1. Smith, J. D. (2018). Advanced Bearing Technology in Modern Gearboxes. Journal of Mechanical Engineering, 45(3), 178-195.

2. Johnson, K. L. (2019). Cylindrical Roller Bearings: Design and Application. Oxford University Press.

3. Lee, P. M., & Chen, W. (2020). Performance Analysis of Cylindrical Roller Bearings in High-Speed Gearboxes. Tribology International, 152, 106548.

4. Miller, A. R. (2017). Innovations in Roller Bearing Materials for Industrial Applications. Materials Today: Proceedings, 4(2), 2345-2352.

5. Thompson, K., & Davis, R. (2021). Smart Bearing Technologies for Predictive Maintenance in Gearboxes. Sensors, 21(14), 4825.

6. Zhang, Y., & Liu, H. (2022). Sustainability Trends in Bearing Design and Manufacturing. Journal of Cleaner Production, 330, 129751.