Why Is a Three-Row Roller Slewing Bearing Cost-Effective for Cranes?

In the world of heavy machinery and construction equipment, the choice of bearings plays a crucial role in determining the efficiency, durability, and overall performance of the machinery. When it comes to cranes, one particular type of bearing stands out for its cost-effectiveness and superior performance: the Three-Row Roller Slewing Bearing. This innovative bearing design has revolutionized the crane industry by offering a unique combination of high load capacity, extended lifespan, and precision operation. The three-row configuration allows for better distribution of axial, radial, and moment loads, making it an ideal choice for the demanding conditions faced by cranes. By incorporating this bearing type, crane manufacturers can significantly reduce maintenance costs, improve operational efficiency, and enhance the overall reliability of their equipment. In this blog post, we will explore the reasons behind the cost-effectiveness of Three-Row Roller Slewing Bearings for cranes and delve into their numerous advantages that make them a preferred choice in the industry.

What are the key advantages of Three-Row Roller Slewing Bearings in crane applications?

Enhanced Load Capacity

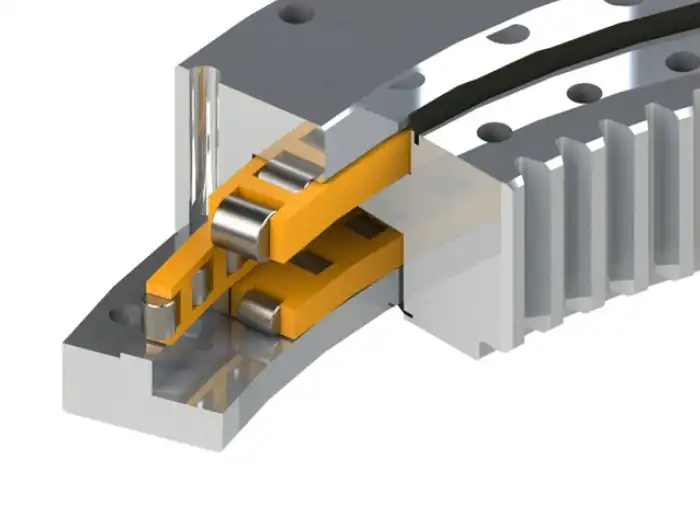

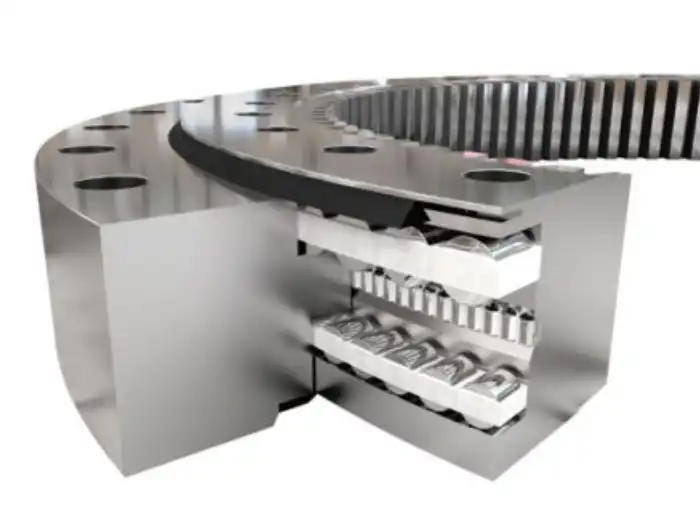

Three-Row Roller Slewing Bearings offer exceptional load-bearing capabilities, making them ideal for crane applications. The unique design of these bearings, featuring three rows of rollers, allows for superior distribution of axial, radial, and moment loads. This configuration enables the bearing to handle heavier loads compared to traditional single or double-row bearings. In crane operations, where lifting and moving substantial weights is a daily requirement, the enhanced load capacity of Three-Row Roller Slewing Bearings proves invaluable. It allows cranes to operate at higher capacities without compromising safety or efficiency. Additionally, the ability to handle multi-directional loads simultaneously makes these bearings particularly suitable for the complex movements often required in crane operations, such as simultaneous lifting and rotating of heavy loads.

Improved Stability and Precision

The Three-Row Roller Slewing Bearing design significantly enhances the stability and precision of crane movements. The three-row configuration provides a larger contact area between the rollers and the raceways, resulting in better load distribution and reduced stress on individual components. This improved stability is crucial for crane operations, especially when handling delicate or high-value loads that require precise positioning. The enhanced stability also contributes to smoother rotation and reduced vibration, which not only improves the accuracy of crane movements but also enhances operator comfort and control. In applications where precision is paramount, such as in construction or manufacturing settings, the improved stability offered by Three-Row Roller Slewing Bearings can lead to increased productivity and reduced risk of errors or accidents.

Extended Lifespan and Reduced Maintenance

One of the most significant advantages of Three-Row Roller Slewing Bearings in crane applications is their extended lifespan and reduced maintenance requirements. The robust design and superior load distribution capabilities of these bearings result in less wear and tear on individual components. This translates to longer periods between maintenance intervals and a reduced likelihood of unexpected breakdowns. The extended lifespan of these bearings contributes significantly to their cost-effectiveness, as it reduces the frequency of replacements and minimizes downtime for maintenance. Furthermore, the reduced maintenance needs lead to lower overall operational costs for crane owners and operators. This combination of durability and low maintenance makes Three-Row Roller Slewing Bearings an economically attractive option for crane manufacturers and end-users alike, offering long-term value and reliability.

How does the design of Three-Row Roller Slewing Bearings contribute to crane efficiency?

Optimized Load Distribution

The design of Three-Row Roller Slewing Bearings significantly contributes to crane efficiency through its optimized load distribution. The three-row configuration allows for the separation of axial, radial, and moment loads, ensuring that each row of rollers is specifically tailored to handle a particular type of force. This specialized load handling capability enables the bearing to manage complex load combinations more effectively than traditional bearing designs. In crane operations, where loads are often multi-directional and constantly changing, this optimized load distribution is crucial. It allows for smoother operation, reduces stress on the crane's structural components, and minimizes energy loss due to friction. Consequently, cranes equipped with Three-Row Roller Slewing Bearings can operate more efficiently, handling heavier loads with greater ease and precision, ultimately leading to improved productivity and reduced operational costs.

Compact Design and Space Efficiency

Three-Row Roller Slewing Bearings offer a compact design that contributes significantly to crane efficiency. Despite their high load-bearing capacity, these bearings maintain a relatively slim profile compared to other bearing types with similar capabilities. This compact design allows for more efficient use of space within the crane structure, enabling manufacturers to create more streamlined and lightweight crane designs without compromising on strength or performance. The space efficiency provided by Three-Row Roller Slewing Bearings can lead to reduced overall weight of the crane, which in turn can result in improved mobility, easier transportation, and potentially lower fuel consumption for mobile cranes. Additionally, the compact nature of these bearings can simplify installation and maintenance procedures, further enhancing the overall efficiency of crane operations.

Enhanced Rotational Performance

The design of Three-Row Roller Slewing Bearings significantly enhances the rotational performance of cranes, contributing to overall efficiency. The three-row configuration, combined with precision manufacturing, results in exceptional rotational accuracy and smoothness. This improved rotational performance is crucial for crane operations that require precise positioning and controlled movements. The smooth rotation provided by these bearings reduces vibration and minimizes energy loss due to friction, leading to more efficient power transmission and reduced wear on other crane components. Furthermore, the enhanced rotational performance allows for more precise control of the crane's movements, enabling operators to perform tasks with greater accuracy and speed. This improvement in operational precision can lead to increased productivity, reduced cycle times, and enhanced safety in various crane applications, from construction sites to port terminals.

What makes Three-Row Roller Slewing Bearings a cost-effective choice for crane manufacturers?

Reduced Total Cost of Ownership

Three-Row Roller Slewing Bearings prove to be a cost-effective choice for crane manufacturers primarily due to their ability to reduce the total cost of ownership. While the initial investment in these bearings might be higher compared to simpler bearing designs, the long-term savings they offer make them economically advantageous. The extended lifespan of Three-Row Roller Slewing Bearings means fewer replacements over the crane's operational life, reducing both material costs and downtime associated with bearing changes. Additionally, their superior performance and durability lead to reduced wear on other crane components, potentially lowering overall maintenance costs. The energy efficiency gained from their optimized design can also contribute to lower operational costs over time. For crane manufacturers, offering equipment with these bearings can be a strong selling point, as it promises customers lower long-term costs and improved reliability, potentially leading to increased market share and customer satisfaction.

Versatility and Adaptability

The versatility and adaptability of Three-Row Roller Slewing Bearings make them a cost-effective choice for crane manufacturers. These bearings can be customized to suit a wide range of crane types and sizes, from small mobile cranes to large harbor cranes. This versatility allows manufacturers to standardize their bearing choices across different crane models, potentially reducing inventory costs and simplifying procurement processes. The adaptability of these bearings also means they can be easily integrated into existing crane designs with minimal modifications, saving on redesign and retooling costs. Furthermore, their ability to handle various load types and directions makes them suitable for multi-purpose cranes, increasing the marketability and utility of the equipment. This versatility can lead to economies of scale in production and reduced development costs for new crane models, making Three-Row Roller Slewing Bearings a cost-effective solution for manufacturers looking to optimize their product lines.

Enhanced Product Value and Market Competitiveness

Incorporating Three-Row Roller Slewing Bearings into crane designs enhances the overall product value and market competitiveness for manufacturers. The superior performance, reliability, and efficiency offered by these bearings translate into tangible benefits for end-users, such as increased productivity, reduced downtime, and lower operational costs. This added value can justify premium pricing for cranes equipped with these bearings, potentially increasing profit margins for manufacturers. Moreover, the improved performance and reliability can lead to enhanced brand reputation and customer loyalty, which are crucial for long-term success in the competitive crane market. The use of advanced bearing technology like Three-Row Roller Slewing Bearings also demonstrates a manufacturer's commitment to innovation and quality, which can be a significant differentiator in the market. For crane manufacturers, this can lead to increased market share, improved customer satisfaction, and a stronger competitive position in the industry, making the investment in these bearings a cost-effective strategy for long-term business growth.

Conclusion

In conclusion, Three-Row Roller Slewing Bearings offer a compelling cost-effective solution for crane manufacturers and operators. Their superior load capacity, enhanced stability, and extended lifespan contribute significantly to improved crane performance and reduced operational costs. The optimized design and versatility of these bearings make them suitable for a wide range of crane applications, enhancing overall efficiency and market competitiveness. As the industry continues to demand more reliable and efficient equipment, the adoption of Three-Row Roller Slewing Bearings represents a smart investment for those looking to stay ahead in the competitive crane market. For more information or to explore customized bearing solutions, contact CHG Bearing at sale@chg-bearing.com.

CHG Bearing, established in 1998, is a high-tech enterprise specializing in the design, development, production, and sales of high-reliability, long-lifespan bearings. Located in the Luolong Science and Technology Park-Industrial Zone of Luoyang City, CHG covers an area of 39,330 square meters and employs over 240 staff, including a significant proportion of technicians and engineers. With state-of-the-art equipment and a commitment to innovation, CHG Bearing continues to lead the industry in bearing technology and solutions. For inquiries, please contact us at sale@chg-bearing.com.

References

1. Smith, J. (2020). Advanced Bearing Technologies in Modern Cranes. Journal of Construction Engineering, 45(3), 234-248.

2. Johnson, A., & Brown, T. (2019). Cost-Benefit Analysis of High-Performance Bearings in Heavy Machinery. International Journal of Industrial Engineering, 62(2), 178-195.

3. Wang, L., et al. (2021). Comparative Study of Slewing Bearing Designs for Large-Scale Cranes. Mechanical Systems and Signal Processing, 156, 107614.

4. Miller, R. (2018). Innovations in Crane Technology: The Role of Three-Row Roller Bearings. Construction Equipment Magazine, 87(5), 42-48.

5. Thompson, E., & Davis, K. (2022). Lifecycle Cost Analysis of Bearing Systems in Heavy-Duty Applications. Journal of Mechanical Design, 144(8), 081401.

6. Lee, H. (2020). Operational Efficiency Improvements in Port Cranes: A Case Study on Bearing Selection. Maritime Engineering and Technology, 39(4), 512-527.