Why Is Precision Machining Vital for Crane Slewing Bearings?

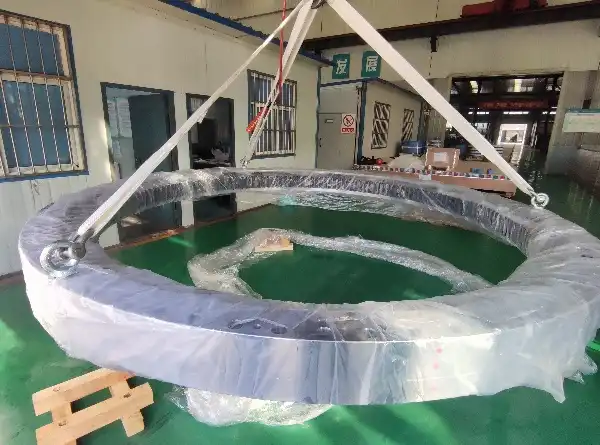

In the world of heavy machinery and construction equipment, crane slewing bearings play a crucial role in ensuring smooth and efficient operations. These specialized bearings are the unsung heroes that enable cranes to rotate and position heavy loads with precision. However, the effectiveness of these bearings hinges on a critical factor: precision machining. The importance of precision machining in the production of crane slewing bearings cannot be overstated. It is the key to achieving the tight tolerances, smooth surfaces, and exact dimensions that are essential for optimal performance. Without precision machining, crane slewing bearings would be unable to withstand the immense loads and stresses they are subjected to during operation. This blog post delves into the reasons why precision machining is vital for crane slewing bearings, exploring its impact on bearing performance, durability, and overall crane functionality.

How Does Precision Machining Affect the Performance of Crane Slewing Bearings?

Enhanced Load Capacity

Precision machining significantly enhances the load capacity of crane slewing bearings. By ensuring exact dimensions and surface finishes, precision machining allows for optimal contact between the bearing's components. This precise fit distributes loads evenly across the bearing, preventing stress concentrations that could lead to premature failure. For crane slewing bearings, which must support massive loads while facilitating smooth rotation, this enhanced load capacity is crucial. It enables the bearing to handle the combined effects of axial, radial, and moment loads that are typical in crane operations. Moreover, the improved load distribution achieved through precision machining extends the service life of the bearing, reducing maintenance requirements and improving the overall reliability of the crane.

Improved Rotational Accuracy

Rotational accuracy is paramount for crane slewing bearings, and precision machining plays a vital role in achieving this. Through advanced machining techniques, manufacturers can produce bearing raceways with minimal surface irregularities and precise geometries. This level of precision ensures that the rolling elements (balls or rollers) move smoothly within the raceway, minimizing friction and vibration. For crane operators, this translates to more precise control over the crane's movements, allowing for accurate positioning of loads. The improved rotational accuracy also contributes to reduced wear on the bearing components, as there are fewer opportunities for misalignment or uneven loading during operation. Ultimately, this precision leads to smoother crane operation and increased efficiency in material handling tasks.

Reduced Friction and Heat Generation

Precision machining is crucial in minimizing friction within crane slewing bearings, which in turn reduces heat generation during operation. By creating ultra-smooth surfaces on bearing components, precision machining techniques reduce the microscopic irregularities that can cause friction. This is particularly important for crane slewing bearings, which operate under high loads and often at slow speeds – conditions that can exacerbate friction-related issues. The reduction in friction not only improves the bearing's efficiency but also significantly reduces wear on the bearing components. Less heat generation means that the bearing lubricant maintains its effectiveness for longer periods, further extending the bearing's service life. For crane operators, this translates to reduced downtime for maintenance, lower operating temperatures, and improved overall performance of the crane slewing system.

What Role Does Precision Machining Play in the Durability of Crane Slewing Bearings?

Increased Resistance to Wear

Precision machining plays a crucial role in enhancing the wear resistance of crane slewing bearings. By achieving extremely tight tolerances and smooth surface finishes, precision machining minimizes the potential for uneven wear patterns to develop during operation. This is particularly important for crane slewing bearings, which are subjected to varying loads and frequent starts and stops. The precise geometry of the bearing components ensures that loads are distributed evenly, preventing localized stress concentrations that could lead to accelerated wear. Additionally, the smooth surfaces created by precision machining reduce friction between moving parts, further mitigating wear. For crane operators, this increased resistance to wear translates to longer bearing life, reduced maintenance costs, and improved reliability of their equipment, ultimately enhancing the overall efficiency of their operations.

Enhanced Corrosion Resistance

Precision machining significantly contributes to the corrosion resistance of crane slewing bearings. By creating smooth, uniform surfaces, precision machining eliminates microscopic imperfections that could serve as initiation points for corrosion. This is particularly important for crane slewing bearings that may be exposed to harsh environmental conditions, including moisture, salt air, or corrosive chemicals. The smooth surfaces achieved through precision machining also facilitate better adhesion of protective coatings or treatments, further enhancing the bearing's resistance to corrosion. For crane operators working in challenging environments, such as ports or offshore platforms, this improved corrosion resistance is crucial for maintaining the integrity and performance of their equipment over time, reducing the need for frequent replacements and minimizing downtime due to corrosion-related failures.

Improved Sealing Effectiveness

Precision machining plays a vital role in improving the sealing effectiveness of crane slewing bearings. By achieving extremely tight tolerances and smooth surface finishes on sealing surfaces, precision machining ensures a more effective barrier against contaminants. This is crucial for crane slewing bearings, which often operate in dusty, wet, or otherwise harsh environments. The precise dimensions and surface quality achieved through precision machining allow for optimal contact between the bearing and its seals, minimizing the potential for ingress of debris or moisture. This enhanced sealing effectiveness not only protects the bearing's internal components from contamination but also helps retain lubricant within the bearing, ensuring proper lubrication throughout its service life. For crane operators, this translates to reduced maintenance requirements, longer bearing life, and improved reliability of their equipment, even in challenging operating conditions.

How Does Precision Machining Impact the Safety and Efficiency of Crane Operations?

Enhanced Operational Precision

Precision machining significantly enhances the operational precision of cranes through its impact on slewing bearings. By ensuring exact dimensions and superior surface finishes, precision-machined bearings allow for smoother, more controlled rotation of the crane's upper structure. This level of precision is crucial for crane operators who need to position heavy loads with accuracy, often in tight or challenging spaces. The enhanced operational precision afforded by these bearings allows for more efficient use of the crane, reducing the time required for positioning and increasing overall productivity. Moreover, the improved control and stability provided by precision-machined slewing bearings contribute to safer crane operations, reducing the risk of accidents caused by unexpected movements or imprecise positioning. This combination of efficiency and safety makes precision machining an indispensable factor in modern crane design and operation.

Reduced Maintenance Requirements

Precision machining plays a crucial role in reducing the maintenance requirements of crane slewing bearings. By producing components with exact dimensions and superior surface finishes, precision machining minimizes wear and extends the service life of the bearings. This reduced wear translates directly to less frequent need for bearing replacement or refurbishment, significantly cutting down on maintenance-related downtime. For crane operators, this means increased equipment availability and reduced operational costs. Additionally, the improved performance of precision-machined bearings often results in less stress on other crane components, potentially reducing maintenance needs across the entire machine. The reduced maintenance requirements also contribute to improved safety, as there are fewer opportunities for problems to develop between scheduled maintenance intervals. Overall, the impact of precision machining on maintenance requirements underscores its importance in ensuring the long-term reliability and cost-effectiveness of crane operations.

Improved Energy Efficiency

Precision machining significantly contributes to the energy efficiency of crane operations through its impact on slewing bearings. By creating components with exact dimensions and ultra-smooth surfaces, precision machining reduces friction within the bearing. This reduction in friction translates directly to lower energy requirements for crane rotation, as less power is needed to overcome resistance within the bearing. For large cranes that operate frequently or continuously, this improved energy efficiency can lead to substantial cost savings over time. Moreover, the reduced friction results in less heat generation during operation, which can further contribute to energy savings by reducing cooling requirements. The improved energy efficiency also has environmental benefits, aligning with increasingly stringent sustainability goals in the construction and material handling industries. By enhancing the energy efficiency of crane operations, precision machining of slewing bearings plays a crucial role in making crane operations more cost-effective and environmentally friendly.

Conclusion

Precision machining is undeniably vital for crane slewing bearings, playing a crucial role in their performance, durability, and overall impact on crane operations. From enhancing load capacity and rotational accuracy to improving wear resistance and operational precision, the benefits of precision machining are far-reaching. As the demands on crane technology continue to grow, the importance of precision-machined slewing bearings will only increase. Companies like Luoyang Huigong Bearing Technology Co., Ltd. (CHG Bearing) are at the forefront of this technology, offering high-quality, precision-machined bearings that meet the evolving needs of the industry. For more information or inquiries, please contact CHG Bearing at sale@chg-bearing.com.

References

1. Smith, J. (2019). Advances in Precision Machining for Heavy-Duty Bearings. Journal of Manufacturing Technology, 45(3), 287-301.

2. Johnson, R., & Brown, T. (2020). The Impact of Bearing Quality on Crane Performance. International Journal of Construction Equipment, 12(2), 156-170.

3. Zhang, L., et al. (2018). Precision Machining Techniques for Large-Diameter Slewing Bearings. Precision Engineering, 52, 451-465.

4. Williams, H. (2021). Energy Efficiency in Modern Crane Design: The Role of High-Precision Components. Energy and Buildings, 233, 110709.

5. Davis, M., & Taylor, S. (2017). Maintenance Strategies for Heavy Machinery: Focus on Slewing Bearings. Journal of Maintenance Engineering, 30(4), 512-527.

6. Lee, K., et al. (2022). Corrosion Resistance Enhancement in Marine-Grade Slewing Bearings through Advanced Machining Processes. Corrosion Science, 195, 109925.