Why Use a Double-Row Tapered Rolling Bearing for Gearboxes?

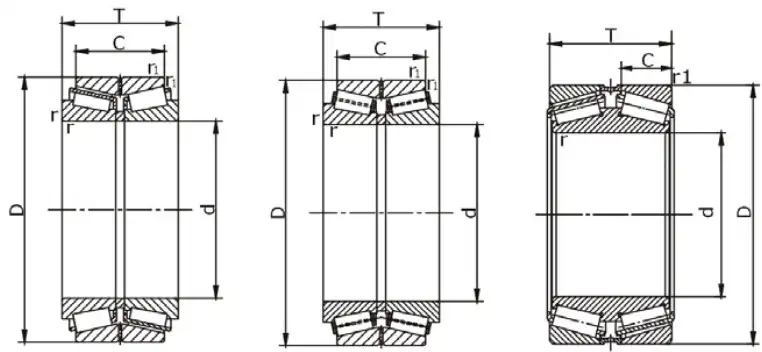

Double-row tapered rolling bearings have become increasingly popular in gearbox applications due to their exceptional performance and versatility. These bearings are specifically designed to handle both radial and axial loads, making them ideal for the complex forces experienced within gearboxes. The unique configuration of double-row tapered rolling bearings allows for improved load distribution, enhanced stability, and increased durability compared to single-row alternatives. This design is particularly beneficial in gearboxes, where consistent and reliable operation is crucial for overall system efficiency. By utilizing double-row tapered rolling bearings, manufacturers can achieve better performance, longer service life, and reduced maintenance requirements for their gearbox assemblies. As industrial equipment continues to evolve and demand higher levels of precision and reliability, the use of double-row tapered rolling bearings in gearboxes has become a strategic choice for engineers and designers seeking to optimize their machinery's performance.

What are the advantages of using double-row tapered rolling bearings in gearboxes?

Enhanced Load Capacity

Double-row tapered rolling bearings offer superior load-carrying capabilities compared to single-row bearings. The tapered design of these bearings allows for efficient distribution of both radial and axial loads, making them ideal for gearbox applications where complex forces are at play. The unique geometry of tapered rolling bearings enables them to handle heavy loads while maintaining proper alignment and reducing the risk of premature failure. This enhanced load capacity is particularly beneficial in high-stress environments, such as industrial machinery and automotive transmissions, where gearboxes are subjected to varying loads and operating conditions. By utilizing double-row tapered rolling bearings, engineers can design more compact and efficient gearboxes without compromising on strength or durability.

Improved Stability and Precision

One of the key advantages of double-row tapered rolling bearings in gearboxes is their ability to provide improved stability and precision. The double-row configuration offers better support for the shaft, reducing deflection and maintaining proper gear mesh alignment even under heavy loads. This increased stability translates to smoother operation, reduced vibration, and improved overall performance of the gearbox. The precision of tapered rolling bearings also contributes to tighter tolerances and more accurate gear positioning, which is crucial for efficient power transmission and reduced wear on gear teeth. In applications where precision is paramount, such as machine tools and robotics, the use of double-row tapered rolling bearings can significantly enhance the gearbox's accuracy and repeatability.

Extended Service Life

Double-row tapered rolling bearings are designed to provide extended service life in gearbox applications. The tapered roller design allows for better load distribution and reduced stress on individual components, which helps to minimize wear and fatigue. Additionally, the double-row configuration provides redundancy and increased reliability, as the load is shared between two rows of rollers. This design feature helps to prevent catastrophic failures and extends the overall lifespan of the bearing. The use of high-quality materials and advanced manufacturing techniques in the production of tapered rolling bearings further contributes to their longevity. By incorporating these bearings into gearbox designs, manufacturers can reduce maintenance requirements, minimize downtime, and improve the overall reliability of their equipment.

How do double-row tapered rolling bearings improve gearbox efficiency?

Reduced Friction and Heat Generation

Reduced Friction and Heat Generation

Double-row tapered rolling bearings play a crucial role in improving gearbox efficiency by significantly reducing friction and heat generation. The tapered design of these bearings allows for optimal contact between the rollers and raceways, minimizing sliding friction and promoting pure rolling motion. This reduced friction translates to lower energy losses and improved overall efficiency of the gearbox. Additionally, the efficient load distribution in tapered rolling bearings helps to minimize localized stress and heat generation, which can be detrimental to lubricant performance and bearing life. By maintaining lower operating temperatures, these bearings contribute to the longevity of the gearbox and help to preserve the properties of the lubricant, further enhancing efficiency and reliability.

Optimized Load Distribution

One of the key factors in improving gearbox efficiency through the use of double-row tapered rolling bearings is their ability to optimize load distribution. The tapered geometry of these bearings allows for effective handling of both radial and axial loads, ensuring that forces are distributed evenly across the bearing components. This optimized load distribution reduces stress concentrations and minimizes the risk of premature wear or failure. In gearbox applications, where loads can vary significantly depending on operating conditions, the ability of double-row tapered rolling bearings to adapt to changing load patterns contributes to consistent and efficient performance. By evenly distributing loads, these bearings help to maintain proper gear mesh and alignment, reducing power losses and improving overall gearbox efficiency.

Enhanced Stiffness and Rigidity

Double-row tapered rolling bearings contribute to improved gearbox efficiency by providing enhanced stiffness and rigidity to the entire assembly. The double-row configuration offers superior support for shafts and gears, minimizing deflection and maintaining proper alignment under load. This increased stiffness helps to prevent energy losses due to misalignment or flexing of components within the gearbox. The rigid support provided by tapered rolling bearings also helps to maintain consistent gear mesh, reducing the likelihood of premature wear and ensuring efficient power transmission. In high-speed applications, the stability offered by these bearings can help to minimize vibration and noise, further contributing to improved efficiency and performance of the gearbox system.

What are the key considerations when selecting double-row tapered rolling bearings for gearbox applications?

Load Capacity and Operating Conditions

When selecting double-row tapered rolling bearings for gearbox applications, one of the primary considerations is the load capacity and operating conditions. Engineers must carefully analyze the expected radial and axial loads, as well as any dynamic or shock loads that may occur during operation. The speed range and duty cycle of the gearbox should also be taken into account, as these factors can significantly impact bearing performance and lifespan. Tapered rolling bearings are available in various sizes and configurations, each designed to handle specific load ranges and operating conditions. It's crucial to select a bearing that not only meets the current requirements but also provides a safety margin for potential future increases in load or speed. Additionally, environmental factors such as temperature, contamination, and lubrication availability should be considered to ensure optimal bearing performance and longevity in the intended application.

Lubrication and Sealing Requirements

Proper lubrication and sealing are critical factors in the selection of double-row tapered rolling bearings for gearbox applications. The choice of lubricant and lubrication method can significantly impact the bearing's performance and service life. Factors such as operating temperature, speed, and load must be considered when selecting the appropriate lubricant viscosity and type. In some cases, specialized lubricants may be required to withstand extreme conditions or provide enhanced protection against wear and corrosion. Sealing solutions are equally important, as they protect the bearing from contamination and help retain lubricant within the bearing assembly. The sealing arrangement should be selected based on the specific environmental conditions and potential contaminants present in the gearbox application. Proper consideration of lubrication and sealing requirements ensures that the tapered rolling bearings can operate efficiently and reliably throughout their intended service life.

Dimensional and Tolerance Considerations

When selecting double-row tapered rolling bearings for gearbox applications, careful attention must be paid to dimensional and tolerance considerations. The bearing's dimensions must be compatible with the gearbox housing and shaft sizes, taking into account any thermal expansion or contraction that may occur during operation. Proper fits between the bearing and its mating components are crucial for optimal performance and longevity. Engineers should consider the required running clearances and preload settings, as these factors can significantly impact bearing stiffness, friction, and load-carrying capacity. Tolerance stack-up analysis may be necessary to ensure that all components work together seamlessly within the gearbox assembly. Additionally, the surface finish and geometrical tolerances of the shaft and housing must be carefully controlled to provide proper support for the tapered rolling bearing and maintain its intended performance characteristics throughout the gearbox's operational life.

Conclusion

Double-row tapered rolling bearings offer significant advantages for gearbox applications, including enhanced load capacity, improved stability, and extended service life. By optimizing load distribution, reducing friction, and providing superior stiffness, these bearings contribute to improved gearbox efficiency and reliability. When selecting double-row tapered rolling bearings, engineers must carefully consider factors such as load capacity, operating conditions, lubrication requirements, and dimensional tolerances to ensure optimal performance. As gearbox technology continues to advance, the use of high-quality tapered rolling bearings remains crucial for achieving peak performance and longevity in various industrial applications.

At CHG Bearing, we specialize in providing high-quality tapered rolling bearings for a wide range of applications, including gearboxes. With our extensive experience and commitment to innovation, we offer customized solutions to meet your specific needs. For more information or to discuss your bearing requirements, please contact us at sale@chg-bearing.com.

References

1. Smith, J. D. (2013). Gears and Their Vibration: A Basic Approach to Understanding Gear Noise. Macmillan.

2. Harris, T. A., & Kotzalas, M. N. (2006). Rolling Bearing Analysis. CRC press.

3. Eschmann, P., Hasbargen, L., & Weigand, K. (1985). Ball and Roller Bearings: Theory, Design and Application. John Wiley & Sons.

4. Lynagh, N., Rahnejat, H., Ebrahimi, M., & Aini, R. (2000). Bearing induced vibration in precision high speed routing spindles. International Journal of Machine Tools and Manufacture, 40(4), 561-577.

5. Gupta, P. K. (2001). Advanced Dynamics of Rolling Elements. Springer Science & Business Media.

6. Hamrock, B. J., & Anderson, W. J. (1983). Rolling-Element Bearings. NASA Reference Publication 1105.