Achieve Greater Accuracy and Longevity with Precision Angular Contact Ball Bearings

The precision engineering industry continues to evolve with increasingly demanding requirements for bearing performance, reliability, and efficiency. Among the various bearing types available, precision angular contact ball bearings have emerged as a crucial component in high-speed and high-precision applications.

As a leading manufacturer in precision bearing technology, Luoyang Huigong Bearing Technology Co., Ltd. brings decades of expertise to the industry. With an experienced R&D team providing technical guidance, customized solutions for different working conditions, 30 years of industry experience, and partnerships with major enterprises, we stand at the forefront of bearing innovation. Our advanced production equipment and testing instruments, combined with over 50 invention patents and certifications including ISO9001 quality management system and ISO14001 environmental management system, demonstrate our commitment to excellence. As a 2024 quality benchmark enterprise, we continue to set industry standards. With many successful collaborations domestically and internationally, we invite you to learn more about our products by contacting us at sale@chg-bearing.com or calling our hotline at +86-0379-65793878.

What Makes Angular Contact Ball Bearings Essential for High-Speed Applications?

Angular contact ball bearings have revolutionized the landscape of high-speed industrial applications through their exceptional design and performance characteristics. The distinctive feature of these bearings lies in their ability to simultaneously handle both radial and axial loads, making them indispensable in precision machinery. The 718 and 719 series exemplify this engineering excellence, offering comprehensive size ranges that cater to diverse industrial requirements. The 718 series, with its inner diameter range of 100-850mm, outer diameter of 128-1030mm, width of 13-82mm, and weight spanning 0.2-140kg, provides remarkable versatility for lighter applications. Complementing this, the 719 series extends these capabilities with inner diameters of 100-750mm, outer diameters of 140-950mm, widths of 20-106mm, and weights ranging from 0.8-195kg, making it ideal for more robust applications. This dimensional diversity ensures optimal performance across various industrial scenarios, from precision manufacturing equipment to heavy industrial machinery. The bearings' unique design incorporates an optimized ball-to-raceway contact angle that facilitates efficient load distribution while maintaining superior rotational speeds. This engineering achievement allows for exceptional performance in applications where traditional bearings might falter, particularly in scenarios demanding both high precision and sustained high-speed operation.

How Do Different Contact Angles Affect Bearing Performance and Selection?

The selection of contact angles in precision angular contact ball bearings represents a critical engineering decision that significantly influences their operational characteristics and application suitability. CHG's comprehensive offering includes three distinct contact angle configurations: 15° (Code C), 25° (Code AC), and 40° (Code B), each engineered to meet specific performance requirements. The 15-degree configuration excels in high-speed applications where axial loads are minimal, making it the preferred choice for precision machine tool spindles and similar high-speed applications. The 25-degree option strikes an optimal balance between speed capability and load handling, providing versatility across a broad spectrum of industrial applications. The 40-degree configuration, while operating at lower speed thresholds, demonstrates superior axial load capacity, making it ideal for applications where robust axial load handling is paramount. This relationship between contact angle and performance characteristics forms the foundation of application-specific bearing selection. Engineers must carefully evaluate factors such as operational speed requirements, load patterns, and environmental conditions to determine the most suitable contact angle configuration. The selection process involves detailed analysis of the application's specific demands, including consideration of factors such as heat generation, lubrication requirements, and expected service life. Understanding these relationships is crucial for optimizing bearing performance and ensuring long-term reliability in industrial applications.

Why Are Ceramic Hybrid Bearings Becoming Increasingly Popular in Precision Applications?

The emergence of ceramic hybrid bearings represents a significant technological advancement in the field of precision bearing technology, combining the superior properties of silicon nitride ceramic rolling elements with high-quality bearing steel rings. This innovative combination has revolutionized bearing performance in demanding applications, particularly in high-speed precision machine tool spindles and advanced manufacturing equipment. The integration of ceramic components offers numerous advantages that address the limitations of traditional all-steel bearings. These benefits include substantially reduced friction coefficients, which translate to lower operating temperatures and decreased power consumption. The ceramic rolling elements' lower density results in reduced centrifugal forces at high speeds, enabling higher operational speeds while maintaining precision and reliability. Furthermore, the superior hardness and wear resistance of silicon nitride ceramics contribute to extended service life, even under challenging operating conditions. The inherent properties of ceramic materials also provide excellent electrical insulation, making these bearings ideal for applications where electrical current leakage must be prevented. In high-speed applications, the thermal stability of ceramic elements proves particularly advantageous, as they maintain their dimensional accuracy even under significant temperature variations. The combination of these properties has led to widespread adoption in industries requiring ultimate precision, such as aerospace manufacturing, medical equipment, and semiconductor production machinery. The performance advantages of ceramic hybrid bearings are particularly evident in applications where traditional bearings face limitations, such as poorly lubricated conditions or environments with extreme temperature variations. This technological advancement has enabled new possibilities in machine tool design and precision manufacturing, contributing to increased productivity and improved product quality across various industrial sectors.

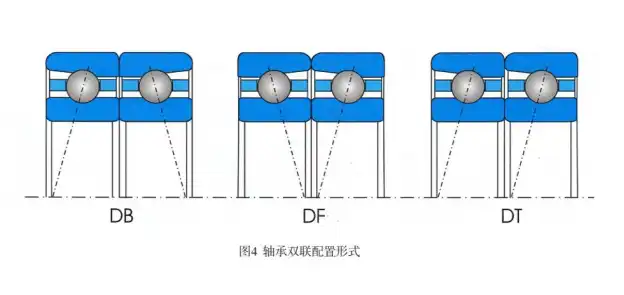

The integration and proper mounting of precision angular contact ball bearings play a crucial role in achieving optimal performance and maximizing service life. Based on application requirements, engineers can choose from various mounting configurations, each offering distinct advantages. Back-to-back arrangements provide superior rigidity and excellent moment load capacity, making them ideal for applications requiring high precision and stability. Face-to-face mounting configurations offer enhanced flexibility in handling thermal expansion, particularly beneficial in applications with significant temperature variations. Tandem arrangements maximize axial load capacity in one direction, suitable for applications with predominant axial loading conditions.

To ensure optimal bearing performance and longevity, CHG implements comprehensive quality control measures throughout the manufacturing process. Our state-of-the-art production facilities utilize advanced CNC machining centers, high-precision grinding equipment, and sophisticated measurement systems, all operating under strictly controlled environmental conditions. This commitment to quality extends to our rigorous testing procedures, ensuring each bearing meets or exceeds industry standards.

Regular maintenance and proper installation procedures significantly impact Precision Angular Contact Ball Bearing life and performance. Key considerations include ensuring proper alignment during installation, applying appropriate preload, maintaining regular lubrication schedules, monitoring operating conditions, and conducting periodic inspections. These practices, combined with our technical expertise and support, help ensure optimal bearing performance throughout their service life.

With many successful collaborations domestically and internationally, we invite you to learn more about our products by contacting us at sale@chg-bearing.com or calling our hotline at +86-0379-65793878.

References:

1. Harris, T. A., & Kotzalas, M. N. (2023). Advanced Concepts of Bearing Technology. CRC Press.

2. SKF Group. (2024). Rolling Bearings Technical Handbook.

3. Hamrock, B. J., & Anderson, W. J. (2023). Rolling-Element Bearings. NASA Technical Reports.

4. International Organization for Standardization. (2024). ISO 492:2024 Rolling bearings — Radial bearings — Geometrical product specifications (GPS) and tolerance values.

5. American Bearing Manufacturers Association. (2024). ABMA Standards for Precision Angular Contact Ball Bearings.