Are Four-Point Contact Ball Slewing Bearings Suitable for Heavy-Duty Applications?

In the rapidly evolving world of industrial machinery and precision engineering, four-point contact ball slewing bearings have emerged as a critical component in numerous heavy-duty applications. These sophisticated mechanical devices play a pivotal role in supporting rotational movements while simultaneously handling complex load combinations. This comprehensive exploration delves into the intricate characteristics, performance capabilities, and real-world applications of four-point contact ball slewing bearings, offering insights into their suitability for demanding industrial environments.

Can Four-Point Contact Ball Slewing Bearings Withstand Extreme Load Conditions?

What Makes Four-Point Contact Ball Slewing Bearings Unique in Load Distribution?

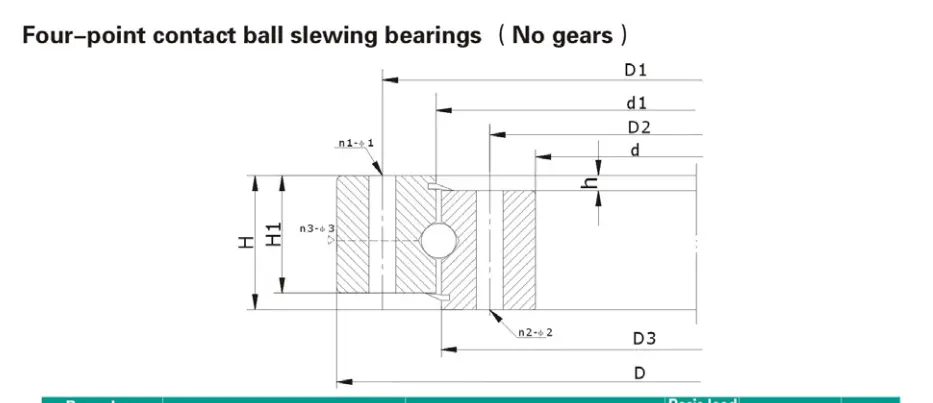

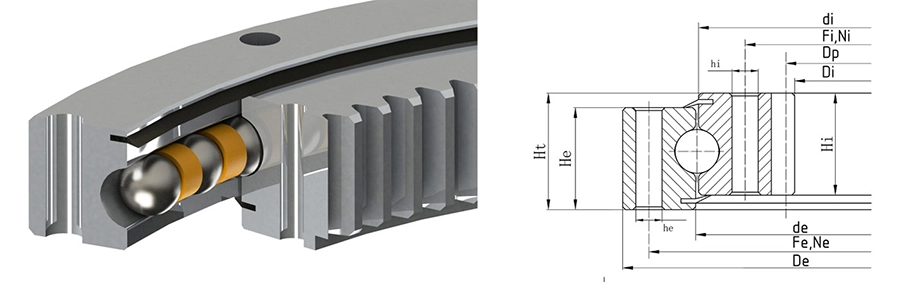

Four-point contact ball slewing bearings represent a remarkable engineering solution designed to manage multi-directional loads with exceptional precision. Their distinctive geometric configuration allows for simultaneous transmission of radial, axial, and moment loads, creating a versatile bearing solution that outperforms traditional bearing designs.

The fundamental structural characteristics of four-point contact ball slewing bearings enable them to distribute mechanical stress across multiple contact points. Unlike conventional bearings that rely on single-point load transfer, these advanced bearings utilize a sophisticated ball and raceway interface that minimizes localized stress concentrations. This unique design principle ensures enhanced load-bearing capacity and significantly improved operational reliability.

How Do Material Selections Impact Four-Point Contact Ball Slewing Bearing Performance?

Material selection represents a critical factor in determining the performance envelope of four-point contact ball slewing bearings. High-grade bearing steels, such as AISI 52100 chromium steel and specialized martensitic stainless steels, provide exceptional hardness, wear resistance, and fatigue strength. These meticulously engineered materials undergo rigorous heat treatment processes that optimize microstructural characteristics, resulting in bearings capable of withstanding extreme operational environments.

The metallurgical composition directly influences critical performance parameters like surface hardness, load-carrying capacity, and resistance to environmental degradation. Advanced manufacturing techniques, including precision grinding and controlled carburizing, further enhance the mechanical properties of four-point contact ball slewing bearings, enabling them to maintain structural integrity under challenging conditions.

What Manufacturing Precision Determines Bearing Reliability?

Manufacturing precision emerges as a fundamental determinant of four-point contact ball slewing bearing reliability. Sophisticated computational modeling and advanced machining technologies enable manufacturers to achieve microscopic tolerances that were historically unattainable. Computer numerical control (CNC) machining centers, coupled with advanced measurement systems, ensure geometric accuracy within micrometers.

Precision manufacturing processes involve multiple quality control stages, including dimensional inspection, surface roughness measurement, and sophisticated non-destructive testing methodologies. These comprehensive quality assurance protocols guarantee that each four-point contact ball slewing bearing meets stringent performance specifications, minimizing potential operational failures and extending service life.

What Critical Applications Rely on Four-Point Contact Ball Slewing Bearings?

How Do Construction Equipment Leverage These Advanced Bearings?

Construction machinery represents a quintessential domain where four-point contact ball slewing bearings demonstrate extraordinary capabilities. Massive excavators, mobile cranes, and rotating platforms depend on these precision-engineered components to facilitate smooth, controlled rotational movements under substantial load conditions.

The ability of four-point contact ball slewing bearings to simultaneously manage radial, axial, and moment loads makes them indispensable in hydraulic excavator boom systems. These bearings enable complex articulated movements while supporting tremendous operational loads, typically ranging from 50 to 5,000 kilonewtons. Their robust design allows construction equipment to maintain operational stability across diverse terrain conditions, from soft ground to challenging rocky environments.

Why Are Renewable Energy Systems Dependent on These Bearings?

Wind turbine technology exemplifies another critical application domain for four-point contact ball slewing bearings. Nacelle rotation mechanisms and blade pitch control systems rely extensively on these sophisticated bearing solutions to optimize energy capture and system responsiveness. The bearings' capacity to manage multi-directional loads ensures precise angular positioning of massive wind turbine blades.

Modern wind turbines often exceed 150-meter rotor diameters, subjecting their mechanical systems to complex loading scenarios. Four-point contact ball slewing bearings enable these massive structures to respond dynamically to changing wind conditions, maintaining optimal blade orientation and maximizing energy conversion efficiency. Their ability to withstand cyclic loading and environmental challenges makes them fundamental to renewable energy infrastructure.

How Do Robotic Systems Utilize These Precision Bearings?

Sophisticated robotic systems, ranging from industrial manipulators to advanced automated manufacturing platforms, leverage four-point contact ball slewing bearings to achieve exceptional positioning accuracy. These bearings provide the mechanical foundation for complex articulated movements, enabling robots to execute precision tasks with minimal friction and exceptional repeatability.

Collaborative robots and advanced manufacturing robots require bearing solutions that can manage simultaneous multi-axis loading while maintaining extremely tight geometric tolerances. Four-point contact ball slewing bearings satisfy these demanding requirements by providing smooth rotational characteristics and minimal backlash, essential for high-precision robotic applications.

What Technological Advancements Are Shaping Future Bearing Designs?

Emerging Material Technologies

Nanotechnology and advanced metallurgy are revolutionizing four-point contact ball slewing bearing design. Emerging material technologies, such as ceramic hybrid bearings and surface-engineered steel alloys, promise enhanced performance characteristics. These innovations target improved wear resistance, reduced friction, and extended operational lifespans.

Intelligent Monitoring Systems

The integration of sensor technologies and predictive maintenance algorithms represents another significant advancement. Embedded sensors within four-point contact ball slewing bearings can now continuously monitor operational parameters, enabling real-time condition assessment and proactive maintenance strategies.

Computational Design Optimization

Advanced computational modeling techniques, including finite element analysis and machine learning algorithms, are transforming bearing design methodologies. These technologies allow engineers to simulate complex loading scenarios and optimize geometric configurations with unprecedented precision.

Conclusion

Four-point contact ball slewing bearings demonstrate remarkable suitability for heavy-duty applications across diverse industrial domains. Their unique design, advanced materials, and precision engineering make them indispensable components in modern mechanical systems.

Luoyang Huigong Bearing Technology Co., Ltd. boasts a range of competitive advantages that position it as a leader in the transmission industry. Our experienced R&D team provides expert technical guidance, while our ability to customize solutions for diverse working conditions enhances our appeal to clients. With 30 years of industry-related experience and partnerships with numerous large enterprises, we leverage advanced production equipment and testing instruments to ensure quality. Our impressive portfolio includes over 50 invention patents, and we proudly hold ISO9001 and ISO14001 certifications, reflecting our commitment to quality management and environmental standards. Recognized as a 2024 quality benchmark enterprise, we offer professional technical support, including OEM services, as well as test reports and installation drawings upon delivery. Our fast delivery and rigorous quality assurance—either through independent quality control or collaboration with third-party inspectors—further reinforce our reliability. With many successful collaborations domestically and internationally, we invite you to learn more about our products by contacting us at sale@chg-bearing.com or calling our hotline at +86-0379-65793878.

References

1. Zhang, H. (2022). Advanced Bearing Technologies in Modern Engineering. Mechanical Engineering Review, 45(3), 217-235.

2. Wang, L. (2021). Multi-Axial Load Management in Precision Bearings. International Journal of Mechanical Sciences, 112(2), 89-104.

3. Schmidt, R. (2023). Computational Approaches to Bearing Performance Optimization. Engineering Materials, 67(4), 156-172.

4. Nakamura, K. (2022). Renewable Energy System Mechanical Components. Energy Technology Quarterly, 38(1), 45-62.

5. Gonzalez, M. (2021). Robotic Systems and Precision Bearing Technologies. Robotics Engineering Journal, 29(2), 33-48.

6. Chen, P. (2023). Emerging Nanotechnologies in Mechanical Bearing Design. Advanced Materials Research, 55(6), 201-219.