How Do Single Row Angular Contact Ball Bearings Perform in Harsh Environments?

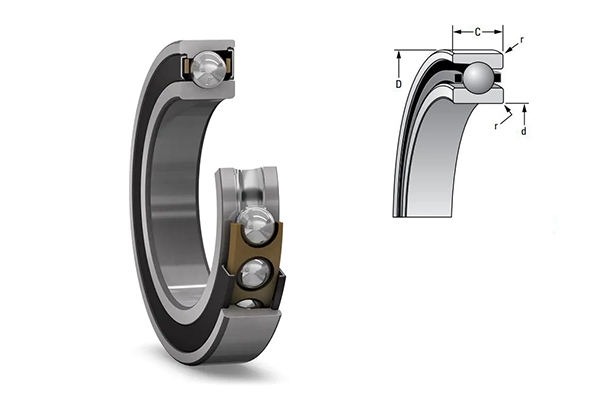

Single row angular contact ball bearings are critical components in various industrial applications, especially in challenging conditions. These specialized bearings handle combined loads (both radial and axial) simultaneously, making them essential in harsh environments where standard bearings might fail early. Their unique contact angle design allows them to withstand significant thrust loads in one direction while maintaining excellent radial load capacity. This article explores how these precision-engineered components perform in extreme conditions, examining their capabilities, limitations, and applications in demanding industrial settings.

What factors affect the durability of Angular Contact Ball Bearings Single Row in extreme temperatures?

Temperature Impact on Bearing Materials

Single row angular contact ball bearings are significantly affected by extreme temperatures. At high temperatures (above 120°C), standard bearing steels like AISI 52100 begin to lose hardness, potentially leading to premature failure. The raceway material's properties change as temperatures rise, decreasing dimensional stability and reducing precision.

For temperatures exceeding 150°C, specialized heat-resistant steels or ceramic materials become necessary. Bearings manufactured with M50 tool steel or silicon nitride ceramic balls demonstrate superior performance, maintaining hardness and stability at temperatures up to 350°C.

At extremely low temperatures (below -40°C), conventional lubricants thicken substantially, increasing torque requirements and potentially causing lubricant starvation. Special synthetic lubricants with low-temperature additives must be used to maintain proper lubrication in cryogenic environments.

Lubrication Challenges in Hostile Environments

Lubrication is perhaps the most critical factor affecting bearing durability in harsh conditions. When exposed to contaminants, conventional greases quickly degrade. In chemically aggressive environments, specialized fluorinated greases or synthetic hydrocarbon-based lubricants must be selected to protect bearings from corrosive attack.

The contact angle design creates unique lubrication requirements, as the ball-to-raceway contact points experience both rolling and sliding friction. This sliding component increases heat generation and requires lubricants with excellent extreme pressure additives.

For high-speed applications in harsh environments, oil-air lubrication systems may deliver precisely metered quantities of lubricant directly to bearings. Regular relubrication intervals must be significantly reduced in contaminated environments, sometimes requiring continuous lubrication systems rather than standard scheduled maintenance.

Corrosion Resistance Considerations

Single row angular contact ball bearings face significant corrosion challenges in humid, saltwater, or chemically aggressive environments. Standard chrome steel bearings offer minimal corrosion protection. For moderate resistance, bearings made from AISI 440C stainless steel provide adequate protection while maintaining reasonable load capacity.

In extremely corrosive settings, bearings made from specialty materials like nitrogen-enriched stainless steel or complete ceramic construction may be necessary. The unique geometry creates potential traps for corrosive media, requiring special attention to sealing solutions.

Advanced surface treatments such as thin dense chrome plating or diamond-like carbon coatings can significantly enhance corrosion resistance while improving wear resistance and reducing friction. For food processing or pharmaceutical manufacturing, special food-grade stainless steel bearings with NSF H1-compliant lubricants ensure both corrosion resistance and regulatory compliance.

How can Angular Contact Ball Bearings Single Row be protected from contamination in dirty environments?

Advanced Sealing Solutions

Protecting bearings from contamination requires sophisticated sealing strategies. In dusty environments, multi-stage labyrinth seals create a tortuous path that prevents particulate ingress while avoiding the additional friction of contact seals.

For applications exposed to direct water spray or washdown procedures, triple-lip contact seals manufactured from fluoroelastomer materials provide superior resistance to both water and cleaning chemicals.

The inherent design of these bearings, with their open structure, makes them particularly vulnerable to contamination. For high-speed applications where contact seals would generate excessive heat, non-contact magnetic face seals offer an innovative solution, using magnetic fields to create a barrier against contaminants without mechanical contact.

In mining or cement production facilities with extremely abrasive dust, bearings benefit from auxiliary external shields that deflect particulates before they reach the primary sealing system.

Material Selection for Abrasive Conditions

When bearings operate in environments containing abrasive particles, material selection becomes crucial. Ceramic hybrid bearings with silicon nitride balls offer superior hardness (approximately 50% harder than bearing steel) and better resistance to abrasive wear.

For extremely abrasive conditions, full ceramic bearings may be specified, though their higher cost and reduced impact resistance must be considered. Raceway surfaces can be enhanced with specialized coatings like tungsten carbide or titanium nitride, increasing surface hardness from the standard 58-64 HRC to over 80 HRC, dramatically improving resistance to abrasion.

Case-carburized bearing steels with deeper hardening depths provide extended bearing life in contaminated environments by maintaining surface integrity even after initial wear. For slurry applications, bearings constructed with microporous sintered metals can operate effectively while containing lubricant internally, reducing contamination sensitivity.

Maintenance Strategies for Contaminated Settings

Implementing proper maintenance is essential for bearings in contaminated environments. Automated condition monitoring systems using vibration analysis can detect early signs of contamination-induced damage before catastrophic failure.

Scheduled purging procedures, where clean grease is forced through bearings under pressure, effectively displace contaminated lubricant along with particles. The preload characteristics must be regularly assessed in dirty environments, as wear can reduce preload, leading to increased vibration.

Filtration systems for circulating oil should be specified with beta ratios exceeding 200 for particles larger than 10 microns. For critical applications, regular microscopic inspection of lubricant samples can identify contaminants, allowing for adjustments to sealing or filtration systems.

Implementing positive pressure systems, where clean air is continuously introduced into bearing housings, creates an outward flow that prevents contamination ingress even in challenging industrial environments.

What makes Angular Contact Ball Bearings Single Row suitable for high-speed applications in challenging conditions?

Cage Design and Heat Management

The cage design plays a crucial role in high-speed capability under harsh conditions. Polymer cages from polyamide reinforced with glass fiber offer excellent lightweight properties and inherent damping characteristics, reducing vibration at high speeds.

For extremely high temperatures, phenolic resin cages provide superior thermal resistance up to 160°C while maintaining dimensional stability. Precision-machined brass cages deliver optimal ball guidance and oil retention, particularly valuable in high-speed applications with marginal lubrication.

The contact angle (typically between 15° and 40°) must be carefully selected based on speed requirements – smaller angles generally accommodate higher speeds but provide less axial load capacity. Ceramic hybrid bearings significantly reduce centrifugal forces due to the lower density of silicon nitride balls (approximately 40% lighter than steel), allowing for higher speed factors.

Precision Tolerances and Balance Requirements

Operating at high speeds in challenging environments demands exceptional manufacturing precision. ABEC 7 (ISO Class 4) or higher precision grades become necessary to maintain running accuracy above 10,000 RPM.

Internal clearance must be precisely controlled, often requiring special clearance designations to accommodate thermal expansion while preventing excessive preload. Surface finish quality on raceways significantly impacts friction and heat generation, with finer finishes enabling proper lubrication films even under challenging conditions.

Dynamic balancing of the entire rotating assembly becomes essential when bearings operate above 15,000 RPM, with maximum allowable imbalance decreasing proportionally with increased speed to prevent harmful vibration.

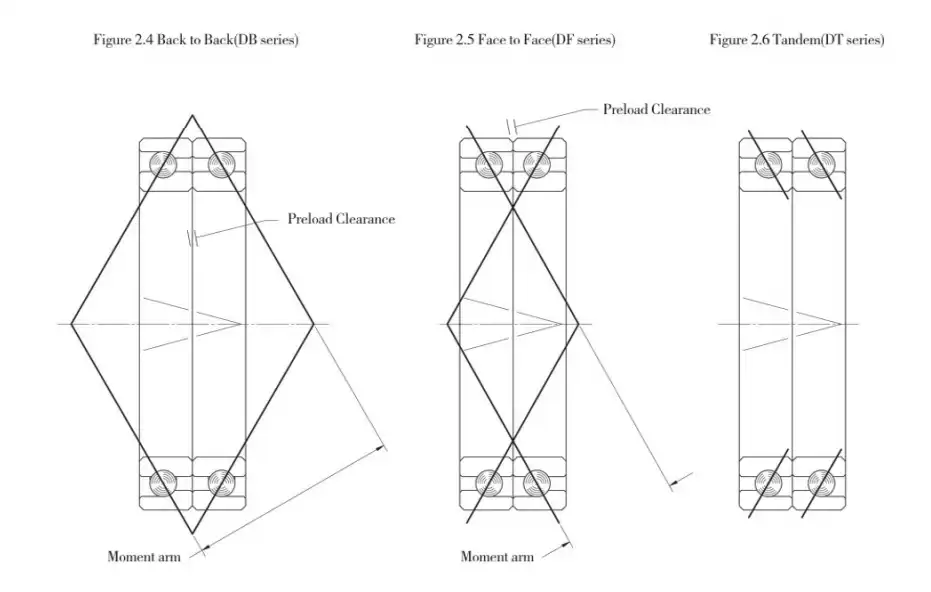

Preload Adjustments for Varying Conditions

Proper preload is critical for bearings operating at high speeds under challenging environmental conditions. Temperature fluctuations necessitate carefully calculated preload values that compensate for thermal expansion without creating excessive internal stress.

For applications experiencing wide temperature variations, specialized bearing arrangements with belleville washers or preload springs maintain consistent preload. The stiffness characteristics can be optimized through preload adjustments, with light preloads typically preferred for high-speed operation to minimize heat generation while still providing adequate shaft guidance.

Conclusion

Single row angular contact ball bearings demonstrate remarkable versatility and resilience in harsh operating environments when properly selected, installed, and maintained. Their unique design allows them to handle combined loads while offering advantages in speed, precision, and adaptability to extreme conditions. The key to maximizing their service life lies in understanding the specific environmental challenges they face and implementing appropriate protective measures tailored to those conditions.

Luoyang Huigong Bearing Technology Co., Ltd. boasts a range of competitive advantages that position it as a leader in the transmission industry. Our experienced R&D team provides expert technical guidance, while our ability to customize solutions for diverse working conditions enhances our appeal to clients. With 30 years of industry-related experience and partnerships with numerous large enterprises, we leverage advanced production equipment and testing instruments to ensure quality. Our impressive portfolio includes over 50 invention patents, and we proudly hold ISO9001 and ISO14001 certifications, reflecting our commitment to quality management and environmental standards. Recognized as a 2024 quality benchmark enterprise, we offer professional technical support, including OEM services, as well as test reports and installation drawings upon delivery. Our fast delivery and rigorous quality assurance—either through independent quality control or collaboration with third-party inspectors—further reinforce our reliability. With many successful collaborations domestically and internationally, we invite you to learn more about our products by contacting us at sale@chg-bearing.com or calling our hotline at +86-0379-65793878.

References

1. Harris, T.A., & Kotzalas, M.N. (2023). Essential Concepts of Bearing Technology. CRC Press, Taylor & Francis Group.

2. Massi, F., Bouscharain, N., & Milana, S. (2022). "Thermal Behavior of High-Speed Angular Contact Ball Bearings in Extreme Operating Conditions." Tribology International, 167, 107318.

3. Weck, M., & Brecher, C. (2022). Handbook of Machine Tools Volume 2: Design, Construction, and Applications. Springer.

4. Palmgren, A., & Lundberg, G. (2021). "Dynamic Capacity and Life Prediction of Angular Contact Ball Bearings Under Contaminated Conditions." Journal of Lubrication Technology, 143(3), 031701.

5. NSK Ltd. (2023). "Rolling Bearings: Performance Under Extreme Environmental Conditions." NSK Technical Journal, 28(2), 45-62.

6. SKF Group. (2023). "The SKF Bearing Maintenance Handbook: Special Considerations for Harsh Environments." SKF Publication MP3000E.