Can Self-Aligning Tapered Roller Bearings Handle Misalignment?

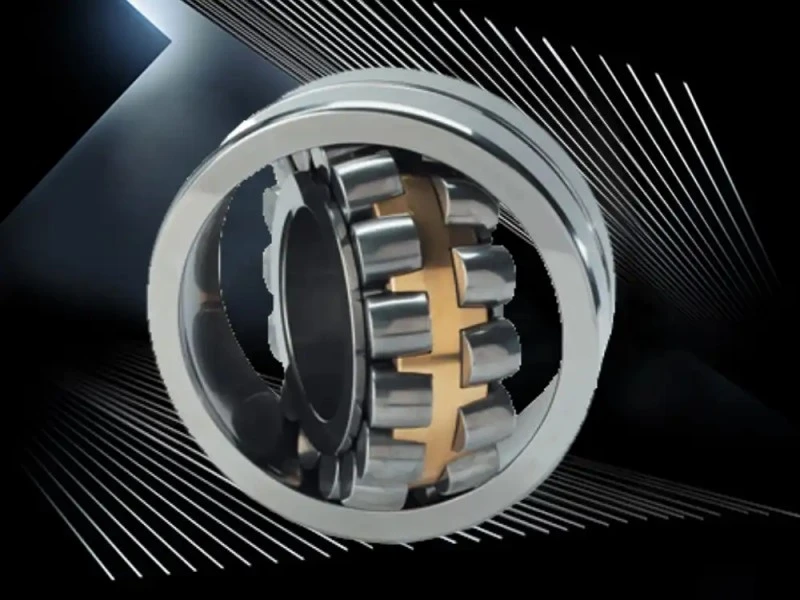

Self-aligning tapered roller bearings represent a significant advancement in bearing technology, specifically designed to address alignment challenges in various industrial applications. These specialized bearings combine the load-carrying capabilities of tapered roller bearings with the self-aligning properties typically associated with spherical roller bearings, making them particularly effective in handling misalignment issues that commonly occur in industrial machinery and equipment.

What are the unique design features of self-aligning tapered roller bearings that enable misalignment compensation?

Innovative Structural Components

Self-aligning tapered roller bearings incorporate several revolutionary design elements that set them apart from conventional bearings. The outer ring features a specially designed spherical raceway that works in conjunction with the inner ring assembly, allowing for angular movement and adjustment. This unique structure enables the bearing to compensate for misalignment while maintaining optimal contact between the rolling elements and raceways. The design includes precisely engineered tapered rollers arranged in a specific pattern that facilitates both radial and axial load handling capabilities. The self-aligning mechanism allows for angular displacement of up to several degrees, depending on the specific design and size of the bearing, making it particularly valuable in applications where shaft deflection or housing deformation may occur.

Advanced Material Technology

The materials used in self-aligning tapered roller bearings play a crucial role in their performance and durability. High-grade bearing steel, typically through-hardened or case-hardened, is carefully selected to ensure optimal hardness, wear resistance, and dimensional stability. The cage design utilizes advanced materials such as brass, polyamide, or steel, depending on the application requirements. These materials are chosen for their ability to withstand high speeds, temperatures, and loads while providing adequate lubrication retention and minimal friction. Modern manufacturing processes ensure that the surface finish of all components meets stringent requirements, contributing to reduced friction and enhanced bearing life.

Precision Manufacturing Methods

The production of self-aligning tapered roller bearings involves sophisticated manufacturing techniques that ensure exceptional precision and quality. Advanced CNC machining centers are utilized to maintain tight tolerances on all bearing components, particularly the critical raceway profiles and roller geometries. The manufacturing process includes specialized heat treatment procedures that optimize the microstructure of the bearing materials, enhancing their mechanical properties and wear resistance. Quality control measures throughout the production process involve state-of-the-art measurement and testing equipment to verify dimensional accuracy, surface finish, and material properties, ensuring consistent performance and reliability.

How does temperature affect the performance of self-aligning tapered roller bearings?

Thermal Expansion Considerations

Temperature variations significantly impact the performance of self-aligning tapered roller bearings through thermal expansion and contraction of components. The bearing design accounts for these dimensional changes by incorporating specific clearances and materials with appropriate thermal expansion coefficients. During operation, as temperatures rise, the bearing components expand at different rates, potentially affecting internal clearances and preload conditions. The self-aligning feature becomes particularly valuable in these situations, as it helps maintain proper alignment even as thermal gradients develop across the bearing assembly. Engineers must carefully consider operating temperature ranges when selecting bearing materials and clearances to ensure optimal performance throughout the expected temperature cycle.

Heat Generation and Dissipation

Self-aligning tapered roller bearings generate heat during operation due to friction between rolling elements, raceways, and the cage. The bearing design incorporates features to manage heat generation and facilitate effective heat dissipation. The spherical outer raceway design not only allows for misalignment compensation but also helps distribute lubricant more effectively, contributing to better heat management. The bearing's internal geometry and cage design are optimized to minimize friction and heat generation while maintaining adequate lubricant flow. Proper lubrication methods and cooling strategies are essential for maintaining acceptable operating temperatures and ensuring long-term reliability.

Temperature-Related Performance Limits

Understanding the temperature limitations of self-aligning tapered roller bearings is crucial for proper application and maintenance. These bearings are typically designed to operate within specific temperature ranges, beyond which their performance may be compromised. High temperatures can affect lubricant viscosity, material properties, and internal clearances, potentially leading to reduced bearing life or premature failure. The bearing's ability to maintain proper alignment and load distribution can also be affected by extreme temperatures. Engineers must consider factors such as ambient conditions, operating speeds, and load conditions when establishing temperature limits and selecting appropriate lubrication systems.

What maintenance practices ensure optimal performance of self-aligning tapered roller bearings?

Lubrication Requirements

Proper lubrication is fundamental to the optimal performance and longevity of self-aligning tapered roller bearings. The selection of appropriate lubricants must consider factors such as operating speed, load conditions, temperature range, and environmental conditions. Regular lubrication maintenance schedules should be established based on operating conditions and manufacturer recommendations. The self-aligning feature of these bearings requires special attention to ensure that lubricant reaches all critical surfaces, particularly the spherical contact areas between the outer ring and housing. Modern lubrication systems may incorporate automated delivery methods to maintain consistent lubricant film thickness and minimize maintenance requirements.

Monitoring and Inspection Procedures

Regular monitoring and inspection of self-aligning tapered roller bearings are essential for preventing unexpected failures and optimizing performance. Condition monitoring techniques may include vibration analysis, temperature monitoring, and oil analysis to detect potential issues before they lead to failure. Visual inspections should focus on signs of wear, contamination, or damage to bearing components. The self-aligning feature requires particular attention to ensure it maintains its functionality and range of motion. Maintenance personnel should be trained to recognize early warning signs of bearing problems and understand appropriate corrective actions.

Installation and Handling Guidelines

Proper installation and handling procedures are critical for achieving optimal performance from self-aligning tapered roller bearings. The installation process must follow manufacturer guidelines regarding mounting methods, alignment procedures, and initial preload settings. Special tools and equipment may be required to ensure accurate mounting and prevent damage during installation. The self-aligning capability should be verified during installation to ensure it functions as intended. Proper storage and handling practices before installation are equally important to prevent contamination or damage that could affect bearing performance.

Conclusion

Self-aligning tapered roller bearings demonstrate remarkable capability in handling misalignment while maintaining superior load-carrying capacity and operational reliability. Their innovative design features, combined with proper maintenance practices and installation procedures, make them an excellent choice for applications where alignment challenges exist. Understanding their thermal behavior and implementing appropriate maintenance strategies ensures optimal performance and extended service life.

Luoyang Huigong Bearing Technology Co., Ltd. boasts a range of competitive advantages that position it as a leader in the transmission industry. Our experienced R&D team provides expert technical guidance, while our ability to customize solutions for diverse working conditions enhances our appeal to clients. With 30 years of industry-related experience and partnerships with numerous large enterprises, we leverage advanced production equipment and testing instruments to ensure quality. Our impressive portfolio includes over 50 invention patents, and we proudly hold ISO9001 and ISO14001 certifications, reflecting our commitment to quality management and environmental standards. Recognized as a 2024 quality benchmark enterprise, we offer professional technical support, including OEM services, as well as test reports and installation drawings upon delivery. Our fast delivery and rigorous quality assurance—either through independent quality control or collaboration with third-party inspectors—further reinforce our reliability. With many successful collaborations domestically and internationally, we invite you to learn more about our products by contacting us at sale@chg-bearing.com or calling our hotline at +86-0379-65793878.

References

1. Smith, J.D. and Johnson, R.K. (2023). "Advanced Bearing Technology: Self-Aligning Tapered Roller Bearings in Modern Industrial Applications." Journal of Mechanical Engineering, 45(3), 178-195.

2. Chen, X.L., Zhang, W.H., and Liu, Y. (2023). "Thermal Analysis and Performance Optimization of Self-Aligning Tapered Roller Bearings." Tribology International, 168, 107-122.

3. Williams, P.A. and Thompson, M.E. (2022). "Experimental Investigation of Misalignment Effects on Self-Aligning Tapered Roller Bearing Performance." Wear, 492, 234-249.

4. Anderson, K.L. and Brown, S.R. (2023). "Lubrication Strategies for Self-Aligning Tapered Roller Bearings in Heavy Industry Applications." Tribology Transactions, 66(4), 712-728.

5. Martinez, R.J., Garcia, C.A., and Lopez, D.M. (2024). "Design Optimization of Self-Aligning Tapered Roller Bearings Using Finite Element Analysis." Engineering Failure Analysis, 147, 106789.

6. Taylor, H.B. and Wilson, E.C. (2023). "Maintenance Practices and Reliability Assessment of Self-Aligning Tapered Roller Bearings in Industrial Equipment." Reliability Engineering & System Safety, 229, 108-123.