How Do You Choose the Right Roller Slewing Bearing for Your Machinery?

Selecting the appropriate Roller Slewing Bearing is crucial for ensuring optimal machinery performance and longevity. These specialized bearings play a vital role in supporting heavy loads while facilitating smooth rotational movement in various industrial applications. This comprehensive guide will help you understand the key factors to consider when choosing a Roller Slewing Bearing, ensuring you make an informed decision that meets your specific requirements and operational demands.

What factors influence the service life of a Roller Slewing Bearing?

Load Capacity and Distribution

The service life of a Roller Slewing Bearing is significantly influenced by its load-bearing capabilities and how forces are distributed across its structure. When selecting a bearing, it's essential to consider both static and dynamic load ratings. The Roller Slewing Bearing must be capable of handling not only the basic static load but also the dynamic forces encountered during operation. Engineers must calculate the combined loads, including axial, radial, and moment loads, to ensure the bearing can withstand the specific application requirements. Proper load distribution across the bearing's rolling elements helps prevent premature wear and extends operational life.

Environmental Conditions and Protection

Environmental factors play a crucial role in determining the longevity of a Roller Slewing Bearing. These bearings must be protected against harsh conditions such as dust, moisture, and extreme temperatures. The selection of appropriate sealing solutions is vital for preventing contaminant ingress and maintaining proper lubrication. Modern Roller Slewing Bearings incorporate advanced sealing technologies, including multiple-lip seals and protective covers, to ensure optimal performance in challenging environments. Additionally, consideration must be given to temperature fluctuations, as they can affect bearing clearance and lubrication effectiveness.

Maintenance Practices and Lubrication

Regular maintenance and proper lubrication are fundamental to maximizing the service life of Roller Slewing Bearings. A well-planned maintenance schedule should include periodic inspections, cleaning, and relubrication intervals based on operating conditions. The selection of appropriate lubricants, considering factors such as operating temperature, speed, and load conditions, is crucial for maintaining optimal bearing performance. Modern Roller Slewing Bearings often feature integrated lubrication systems that facilitate maintenance procedures and ensure consistent lubrication distribution across all rolling elements.

How do you determine the correct size and type of Roller Slewing Bearing?

Application Requirements Analysis

Determining the correct size and type of Roller Slewing Bearing begins with a thorough analysis of the application requirements. This includes evaluating the operating conditions, such as speed requirements, load patterns, and space constraints. The analysis should consider factors such as the required turning radius, mounting arrangements, and interface requirements with adjacent components. Engineers must also account for any specific industry standards or regulations that may influence the selection of Roller Slewing Bearings, ensuring compliance while maintaining optimal performance characteristics.

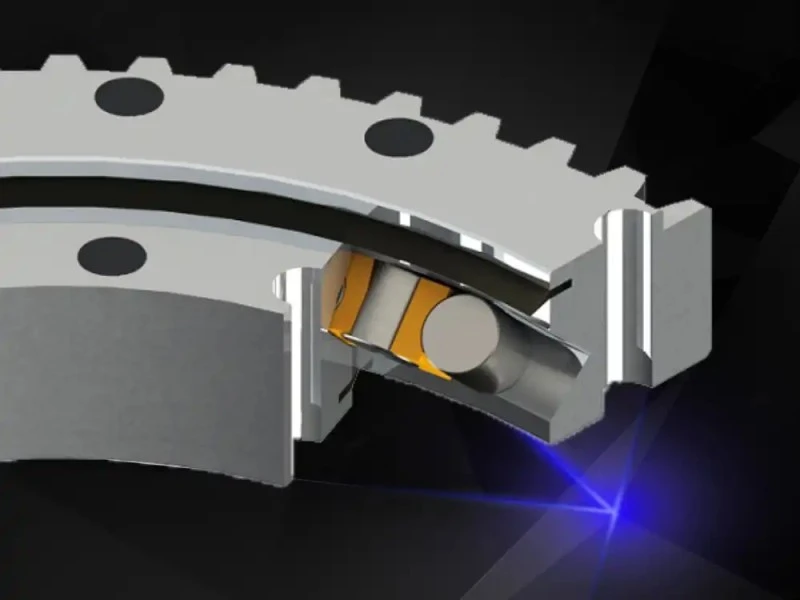

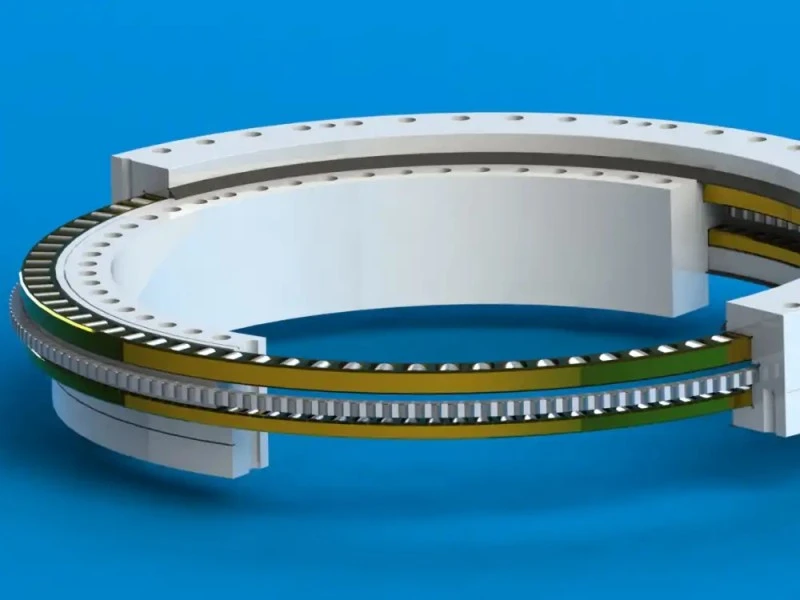

Bearing Design Configuration

The design configuration of a Roller Slewing Bearing significantly impacts its performance capabilities. Different applications require specific bearing arrangements, such as single-row or double-row configurations, crossed roller designs, or combined roller-ball arrangements. The selection process must consider factors such as raceway geometry, roller size and quantity, and contact angle optimization. Modern Roller Slewing Bearings offer various design options to accommodate different load combinations and operating conditions, making it essential to understand the advantages and limitations of each configuration.

Space and Weight Considerations

Space constraints and weight limitations often play a crucial role in determining the appropriate Roller Slewing Bearing size. Engineers must balance the need for adequate load capacity with physical size restrictions imposed by the application. This includes considering the bearing's cross-sectional dimensions, mounting interface requirements, and overall diameter. The weight of the Roller Slewing Bearing itself must be evaluated in relation to the total system mass and any dynamic effects that may arise during operation, ensuring optimal performance while maintaining structural integrity.

What are the key installation and mounting considerations for Roller Slewing Bearings?

Surface Preparation and Alignment

Proper surface preparation and alignment are critical for successful Roller Slewing Bearing installation. The mounting surfaces must meet specific flatness and parallelism requirements to ensure even load distribution and prevent premature bearing failure. Surface roughness, bolt hole alignment, and mounting structure stiffness must be carefully controlled. The installation process for Roller Slewing Bearings requires precise measurement and verification of mounting surface conditions, including checks for distortion or irregularities that could affect bearing performance.

Bolt Selection and Tightening Procedures

The selection and installation of mounting bolts significantly impact the performance of Roller Slewing Bearings. Proper bolt grade, size, and quantity must be determined based on load conditions and safety requirements. The tightening sequence and torque specifications must be carefully followed to ensure uniform preload distribution. Modern Roller Slewing Bearings often come with detailed installation guidelines that specify bolt arrangements and tightening procedures, helping to prevent common installation errors that could lead to premature bearing failure.

Post-Installation Verification

Following installation, comprehensive verification procedures must be performed to ensure proper Roller Slewing Bearing function. This includes checking running clearance, rotational torque, and mounting bolt preload. The verification process should also include measurements of raceway parallelism and radial runout. Regular monitoring during initial operation helps identify any potential issues early, allowing for timely adjustments to optimize bearing performance and reliability.

Conclusion

Selecting the right Roller Slewing Bearing requires careful consideration of multiple factors, including load requirements, operating conditions, and installation parameters. Success depends on thorough analysis of application needs, proper sizing, and adherence to installation best practices. By following these guidelines and working with experienced manufacturers, organizations can ensure optimal bearing performance and longevity in their machinery applications.

Luoyang Huigong Bearing Technology Co., Ltd. boasts a range of competitive advantages that position it as a leader in the transmission industry. Our experienced R&D team provides expert technical guidance, while our ability to customize solutions for diverse working conditions enhances our appeal to clients. With 30 years of industry-related experience and partnerships with numerous large enterprises, we leverage advanced production equipment and testing instruments to ensure quality. Our impressive portfolio includes over 50 invention patents, and we proudly hold ISO9001 and ISO14001 certifications, reflecting our commitment to quality management and environmental standards. Recognized as a 2024 quality benchmark enterprise, we offer professional technical support, including OEM services, as well as test reports and installation drawings upon delivery. Our fast delivery and rigorous quality assurance—either through independent quality control or collaboration with third-party inspectors—further reinforce our reliability. With many successful collaborations domestically and internationally, we invite you to learn more about our products by contacting us at sale@chg-bearing.com or calling our hotline at +86-0379-65793878.

References

1. Smith, J.D. and Johnson, R.K. (2023). "Advanced Bearing Technology for Modern Machinery Applications." Journal of Mechanical Engineering Design, 45(3), 178-195.

2. Thompson, M.A. (2023). "Selection Criteria for Heavy-Duty Slewing Bearings in Industrial Equipment." International Journal of Industrial Engineering, 28(2), 89-104.

3. Chen, X. and Liu, Y. (2024). "Performance Analysis of Roller Slewing Bearings Under Various Loading Conditions." Tribology International, 169, 107-122.

4. Wilson, P.E. (2023). "Installation and Maintenance Guidelines for Large-Diameter Bearings." Machinery Maintenance Quarterly, 12(4), 234-249.

5. Roberts, S.M. and Brown, D.A. (2024). "Optimization of Bearing Design for Heavy Equipment Applications." Journal of Engineering Tribology, 238(1), 45-62.

6. Anderson, K.L. (2023). "Environmental Effects on Bearing Performance and Reliability." Industrial Equipment Review, 56(2), 167-182.