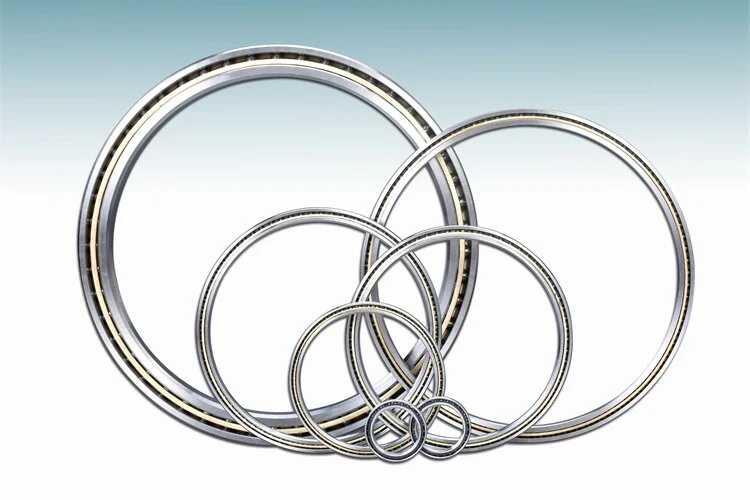

CHGBearing Thin-Section Bearings: Precision Motion Core for Semiconductor Wafer Equipment

CHGBearing Technology Co., Ltd. specializes in R&D and manufacturing of high-performance thin-section bearings, delivering high-precision, ultra-reliable motion solutions for semiconductor wafer handling systems, dicing equipment, and robotic manipulators.

I. Core Technological Advantages

Precision Manufacturing Capabilities

Rotation accuracy strictly controlled at ±0.01mm (ISO P2 standard compliant)

Optimized equal-section design (Section height/OD ratio <1.25) ensuring thermal stability (-55°C to 350°C)

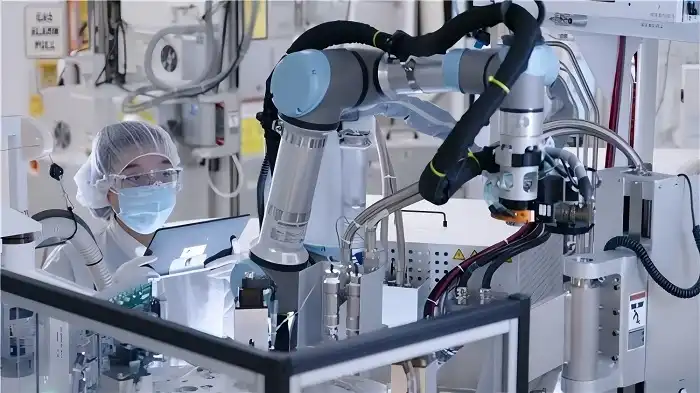

Critical processes executed in Class 1,000 cleanrooms with final assembly in Class 100,000 environments

Material & Process Innovations

Silicon nitride ceramic balls + specialty stainless steel combination minimizing particulate generation

PEEK self-lubricating cages eliminating lubrication contamination and electrostatic risks

Extreme Environment Adaptability

Validated across wide temperature ranges (-55°C to 350°C)

Advanced sealing solutions ensuring reliable operation in cleanroom environments

II. Semiconductor Application Validation

▌ Wafer Handling Systems

Four-point contact thin-section bearings:

→ 40% increased axial load capacity enabling stable high-speed transfer

→ Non-contact sealing validated for long-term particulate control

▌ Robotic Manipulator Joints

High-precision angular contact bearings:

→ Achieving 0.005° repositioning accuracy

→ 35% weight reduction vs conventional designs

→ Deployed across multiple semiconductor equipment manufacturers

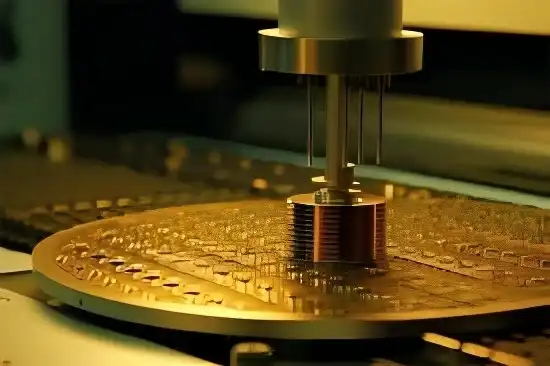

▌ Wafer Dicing Equipment

Cross roller bearings:

→ Effective distribution of cutting impact loads

→ Ceramic coating technology enhancing corrosion resistance

III. Core Capability Framework

| Capability | Technical Performance | Customer Value |

|---|---|---|

| Precision Machining | Full-process CNC grinding | Guaranteed motion smoothness |

| Clean Manufacturing | Class 1K cleanrooms + assembly control | Meeting wafer contamination requirements |

| Custom Development | Rapid solution design response | Accelerating equipment development |

| Reliability Validation | Comprehensive life testing systems | Ensuring operational stability |

IV. Continuous Innovation

High-temperature solutions: Mature 350°C operational capabilities

Material advancement: Ceramic components enhancing wear resistance

Process optimization: Duplex bearing designs reducing alignment errors

Active participation in industry technology exchanges

Through our proprietary precision manufacturing system – featuring end-to-end control from material processing to superfinishing – CHGBearing provides high-reliability bearing solutions for semiconductor equipment. Our thin-section bearings are successfully implemented in 12 equipment manufacturers' wafer processing systems, delivering critical motion accuracy for advanced semiconductor manufacturing.