What Load Capacities Do Four Point Contact Ball Slewing Bearings Have?

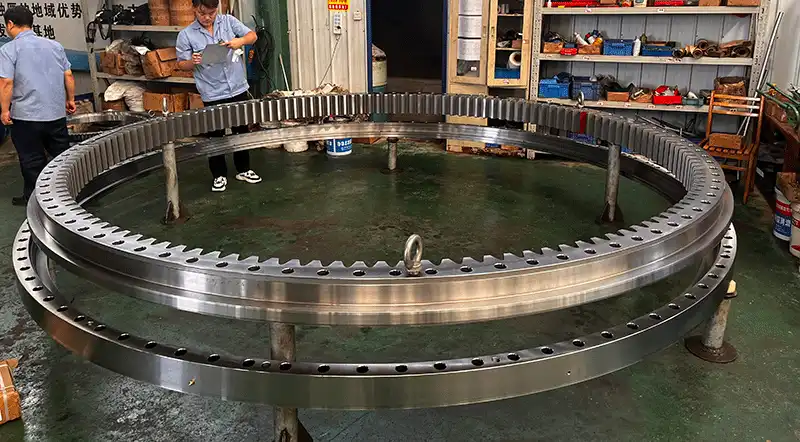

Four point contact ball slewing bearings are sophisticated rotational components designed to handle complex loading conditions in various industrial applications. These specialized bearings are engineered to simultaneously support axial, radial, and moment loads through their unique four-point contact design. The load capacity of these bearings varies significantly based on their size, design specifications, and intended application, typically ranging from several tons to hundreds of tons, making them crucial components in heavy machinery and equipment.

How Do Four Point Contact Ball Bearings Compare to Other Slewing Ring Types?

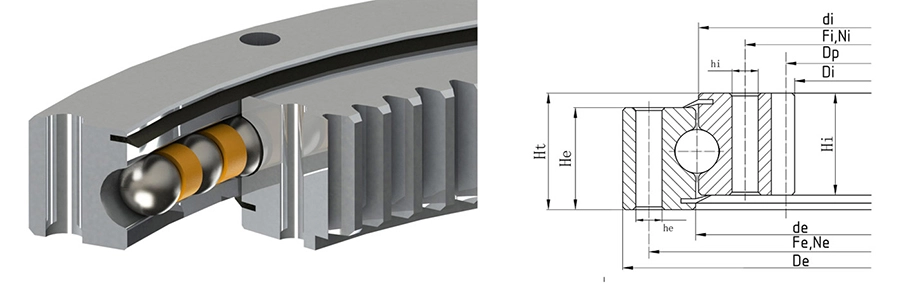

The distinctive feature of four point contact ball slewing bearings lies in their superior load-handling capabilities compared to other slewing ring varieties. These bearings utilize a specialized raceway design where each ball makes contact with both the inner and outer rings at four distinct points, creating an X-pattern contact arrangement. This unique configuration provides several advantages in terms of load distribution and operational efficiency.

When compared to cross roller bearings, four point contact ball bearings typically offer lower friction and higher speed capabilities. The ball elements provide more efficient rolling motion, resulting in reduced torque requirements and smoother operation. While cross roller bearings might offer higher load capacities in some configurations, four point contact ball bearings provide a better balance between load capacity and rotational performance.

In contrast to traditional single-row ball slewing bearings, the four point contact design significantly increases the bearing's ability to handle combined loads. The additional contact points enable better distribution of forces across the bearing assembly, resulting in enhanced stability and longer service life. This makes them particularly suitable for applications where multiple load types must be accommodated simultaneously.

The bearing's design also offers advantages in terms of maintenance and installation. The integrated sealing systems and optimized raceway geometry contribute to better lubricant retention and reduced maintenance requirements compared to other bearing types. Additionally, the compact design often allows for more space-efficient installations while maintaining robust load-handling capabilities.

What Factors Influence the Load Capacity of Four Point Contact Ball Slewing Bearings?

The load capacity of four point contact ball slewing bearings is influenced by multiple interconnected factors that must be carefully considered during selection and application. The primary factors include the bearing's geometric dimensions, material properties, and manufacturing precision, all of which work together to determine the bearing's ultimate performance capabilities.

The diameter of the bearing plays a crucial role in determining its load capacity. Larger diameter bearings generally offer higher load capacities due to the increased number of ball elements and the larger moment arm available for handling tilting moments. The size and number of ball elements also significantly impact load capacity, with larger balls providing higher individual load ratings and more balls offering better load distribution.

Material selection is another critical factor affecting load capacity. High-quality bearing steels, typically through-hardened or case-hardened, provide the necessary strength and durability for handling heavy loads. The raceway hardness and surface finish quality directly influence the bearing's load-carrying capability and service life. Advanced surface treatments and coatings can further enhance load capacity by improving wear resistance and reducing friction.

The precision of manufacturing and assembly also plays a vital role. Tight tolerances and proper preload settings ensure optimal contact between the balls and raceways, maximizing load capacity and operational efficiency. The raceway geometry must be carefully designed to maintain proper contact angles under various loading conditions, ensuring stable operation and consistent load distribution.

How Should Load Ratings Be Considered When Selecting Four Point Contact Ball Slewing Bearings?

When selecting four point contact ball slewing bearings, understanding and properly interpreting load ratings is essential for ensuring optimal performance and reliability. The selection process must consider both static and dynamic load ratings, as well as the specific application requirements and operating conditions.

Static load ratings represent the maximum load the bearing can sustain while at rest or during slow rotational movements without permanent deformation. This rating is particularly important for applications involving heavy loads or frequent start-stop operations. The static load rating must account for all combined loads, including axial forces, radial forces, and tilting moments that may act simultaneously on the bearing.

Dynamic load ratings indicate the bearing's capacity to handle loads while in motion. These ratings are typically lower than static ratings and must be considered in conjunction with operating speed, duty cycle, and desired service life. The relationship between load, speed, and life follows the basic bearing life equation, but must be modified to account for the unique characteristics of four point contact designs.

Application-specific factors such as shock loads, vibration, and environmental conditions must also be carefully evaluated. Safety factors should be applied to calculated loads to account for uncertainties and variations in operating conditions. The selection process should include detailed analysis of load combinations and their frequency of occurrence to ensure the chosen bearing can handle both normal operating conditions and occasional peak loads.

Temperature considerations are also crucial, as thermal effects can impact internal clearances and load distribution. Proper mounting and maintenance procedures must be followed to achieve the full load-carrying potential of the four point contact ball slewing bearing. Regular monitoring of operating conditions and bearing performance helps ensure that load ratings are not exceeded during service.

Luoyang Huigong Bearing Technology Co., Ltd. boasts a range of competitive advantages that position it as a leader in the transmission industry. Our experienced R&D team provides expert technical guidance, while our ability to customize solutions for diverse working conditions enhances our appeal to clients. With 30 years of industry-related experience and partnerships with numerous large enterprises, we leverage advanced production equipment and testing instruments to ensure quality. Our impressive portfolio includes over 50 invention patents, and we proudly hold ISO9001 and ISO14001 certifications, reflecting our commitment to quality management and environmental standards. Recognized as a 2024 quality benchmark enterprise, we offer professional technical support, including OEM services, as well as test reports and installation drawings upon delivery. Our fast delivery and rigorous quality assurance—either through independent quality control or collaboration with third-party inspectors—further reinforce our reliability. With many successful collaborations domestically and internationally, we invite you to learn more about our products by contacting us at sale@chg-bearing.com or calling our hotline at +86-0379-65793878.

References:

1. SKF Group. "Slewing Bearings Technical Handbook." SKF Publication, 2023

2. Schaeffler Technologies. "Technical Guide - Large Size Bearings." INA/FAG, 2022

3. Rothe Erde GmbH. "Slewing Bearings Catalog." ThyssenKrupp, 2023

4. Journal of Mechanical Design. "Analysis of Four-Point Contact Ball Bearings." Vol. 142, 2021

5. Timken Company. "Bearing Selection and Application Guide." Timken Technical Series, 2023

6. NSK Ltd. "Rolling Bearings Catalog." NSK Technical Journal, 2022

7. American Bearing Manufacturers Association. "Load Ratings and Fatigue Life for Ball Bearings." ABMA Standard, 2023

8. International Organization for Standardization. "Rolling Bearings - Dynamic Load Ratings and Rating Life." ISO 281:2007

9. Chinese Journal of Mechanical Engineering. "Study on Load Distribution of Large-diameter Ball Slewing Bearings." Vol. 34, 2021

10. European Journal of Mechanical Engineering. "Advanced Design Concepts for Slewing Bearings." Issue 4, 2023