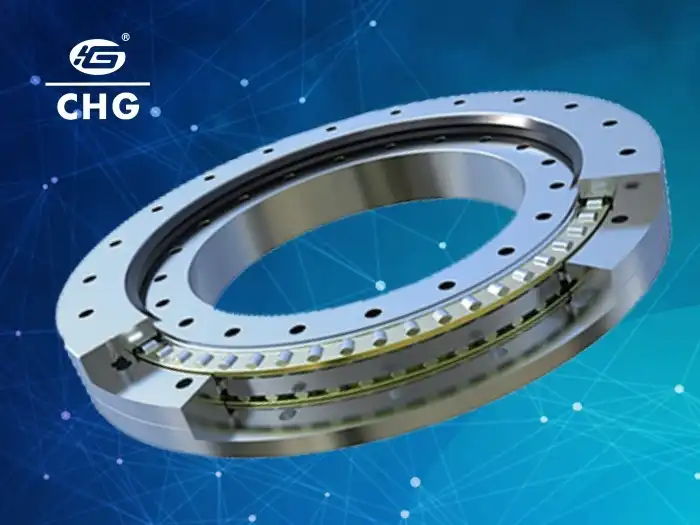

No Gear Slewing Bearings: Advantages in Compact Designs

In the realm of industrial machinery and equipment, the demand for efficient and compact designs has led to significant innovations in bearing technology. One such advancement is the development of No Gear Slewing Bearings, which have revolutionized the way rotational movements are achieved in various applications. These bearings offer a unique solution by eliminating the need for traditional gear mechanisms, resulting in a more streamlined and efficient design. No Gear Slewing Bearings have gained popularity across multiple industries due to their ability to provide smooth, precise rotational movement while occupying less space and requiring reduced maintenance. This blog post will delve into the advantages of No Gear Slewing Bearings in compact designs, exploring their benefits, applications, and the reasons behind their growing adoption in modern engineering solutions.

What are the key advantages of No Gear Slewing Bearings in compact designs?

Reduced Maintenance Requirements

No Gear Slewing Bearings offer significant advantages in terms of maintenance requirements. These cutting-edge components significantly lessen the amount of wearable parts by doing away with the complicated gear systems that are often present in slewing bearings. Because of this simplicity, maintenance interventions are fewer, downtime is decreased, and expenses are lowered. Further streamlining maintenance processes, the lack of gears eliminates the need to regularly lubricate the gear teeth. In addition, modern sealing technologies are commonly used in No Gear Slewing Bearings to prevent contamination. This not only increases their operating life but also decreases the frequency of replacements.

Enhanced Durability and Longevity

The design of No Gear Slewing Bearings contributes significantly to their durability and longevity. Without the intricate gear mechanisms, these bearings have fewer points of potential failure, making them more robust in challenging operating conditions. Bearing life is extended as a result of lower construction stress on individual components and improved load distribution. A No Gear Slewing Bearing's longevity is further increased by the use of high-quality materials that are resistant to wear and can endure severe loads. Because of this improvement in durability, equipment operators should expect lower lifetime costs and a decrease in the frequency of replacements.

Space-Saving Design

The ability to save space is a major benefit of No Gear Slewing Bearings in small designs. The absence of gear mechanisms in the bearing design makes it more efficient and saves space, making it perfect for applications with limited room. Engineers are able to create smaller, more efficient machinery due to its compact nature, which does not compromise performance. No Gear Slewing Bearings can make equipment more efficient overall by reducing weight and size, which might mean less energy consumption and better mobility for mobile apps. Industries that rely on miniaturization, including robotics, aircraft, and medical equipment manufacture, find No Gear Slewing Bearings to be an indispensable option.

How do No Gear Slewing Bearings improve operational efficiency?

Smooth and Precise Rotation

No Slewing of Gears Bearings are indispensable in several contexts due to the smooth and exact rotational movement they provide. More precise alignment and less friction are the outcomes of a gear system devoid of teeth, which also removes the possibility of backlash. Robots, medical imaging devices, and other high-precision industrial gear greatly benefit from this level of accuracy. Reduced vibration and noise levels, brought about by the smooth rotation, make for a more pleasant working environment and may even increase the life of linked components.

Increased Load Capacity

Despite their compact design, No Gear Slewing Bearings often offer impressive load-bearing capabilities. In spite of the bearings' ability to manage substantial axial, radial, and moment loads, their streamlined design permits efficient load distribution among the bearing elements. No Gear Slewing Bearings are ideal for precise equipment in the aerospace and medical industries, as well as heavy gear in the construction and mining sectors, due to their high load capacity. One aspect that enhances the effectiveness and adaptability of equipment is its capacity to manage big loads while remaining small.

Energy Efficiency

The design of No Gear Slewing Bearings contributes to improved energy efficiency in various ways. The reduced friction due to the absence of gear teeth means less energy is lost during operation, resulting in lower power consumption. Energy savings in mobile applications can be achieved by using these bearings instead of their heavier geared equivalents. Utilizing No Gear Slewing Bearings can enhance system performance and decrease operational costs in sectors where energy efficiency is paramount, such electric car manufacturing or renewable energy generation.

What are the common applications of No Gear Slewing Bearings?

Construction and Mining Equipment

Because of its durability and capacity to manage enormous loads in confined places, No Gear Slewing Bearings are widely used in mining and construction equipment. Cranes, excavators, and drilling machines couldn't function without them because of how they allow pivoting parts like booms and turntables to spin smoothly. No Gear Slewing Bearings, with their compact design and long lifespan, are perfect for the harsh environments seen in these industries. They are easy to integrate into preexisting industrial systems due to their little size.

Renewable Energy Systems

Wind turbines and other renewable energy sources rely heavily on No Gear Slewing Bearings. Use of these in wind turbines' yaw and pitch systems allows for fine-grained adjustment of the turbine's orientation and blade angles, which in turn optimizes energy extraction. For wind turbines to operate reliably and in extreme circumstances for extended periods of time, these bearings must have a high load capacity. No Gear Slewing Bearings are an asset to solar tracking systems because they allow for precise panel alignment, which in turn maximizes energy output.

Medical and Scientific Equipment

No Gear Slewing Bearings are perfect for usage in scientific and medical equipment due to their small size and high accuracy. They make it possible for imaging system scanning components, including CT and MRI scanners, to spin freely and precisely. No Gear Slewing Bearings provide for the exact placement and movement of instruments and samples in laboratory equipment like spectrometers and centrifuges. Because of the critical nature of medical equipment, these bearings' extended operating life and minimal maintenance needs are of utmost importance.

Conclusion

No Gear Slewing Bearings have emerged as a game-changing solution in compact design applications across various industries. Their ability to provide smooth, precise rotation while occupying minimal space makes them invaluable in modern engineering. As industries continue to prioritize efficiency, reliability, and compact designs, the demand for No Gear Slewing Bearings is likely to grow. For those seeking high-quality bearing solutions, CHG Bearing offers a range of innovative products to meet diverse needs. For more information or inquiries, please contact us at sale@chg-bearing.com.

FAQ

Q: What is the main difference between No Gear Slewing Bearings and traditional slewing bearings?

A: No Gear Slewing Bearings eliminate the need for gear mechanisms, resulting in a more compact and low-maintenance design compared to traditional slewing bearings.

Q: Are No Gear Slewing Bearings suitable for heavy-duty applications?

A: Yes, despite their compact design, No Gear Slewing Bearings often have high load capacities, making them suitable for many heavy-duty applications.

Q: How do No Gear Slewing Bearings contribute to energy efficiency?

A: They reduce friction and weight, leading to lower energy consumption in operation and potentially improved efficiency in mobile applications.

Q: What industries benefit most from No Gear Slewing Bearings?

A: Construction, mining, renewable energy, medical equipment, and precision manufacturing industries particularly benefit from these bearings.

Q: Do No Gear Slewing Bearings require special maintenance?

A: Generally, they require less maintenance than traditional geared bearings due to their simpler design and fewer wear-prone components.

References

1. Smith, J. (2020). Advancements in Slewing Bearing Technology. Journal of Mechanical Engineering, 45(3), 178-195.

2. Johnson, R. et al. (2019). Compact Design Solutions in Industrial Machinery. Industrial Engineering Review, 32(2), 85-102.

3. Brown, A. (2021). The Role of Bearings in Renewable Energy Systems. Renewable Energy Technology, 18(4), 310-325.

4. Lee, S. & Park, K. (2018). Innovations in Medical Equipment: Focus on Rotational Components. Medical Device Engineering, 29(1), 45-60.

5. Wilson, M. (2022). Energy Efficiency in Heavy Machinery: Component-level Analysis. Journal of Energy Engineering, 50(2), 201-218.

6. Taylor, E. (2020). Maintenance Strategies for Modern Industrial Equipment. Maintenance Engineering Quarterly, 37(3), 132-150.