Do Turntables Require 4 Point Contact Ball Bearings?

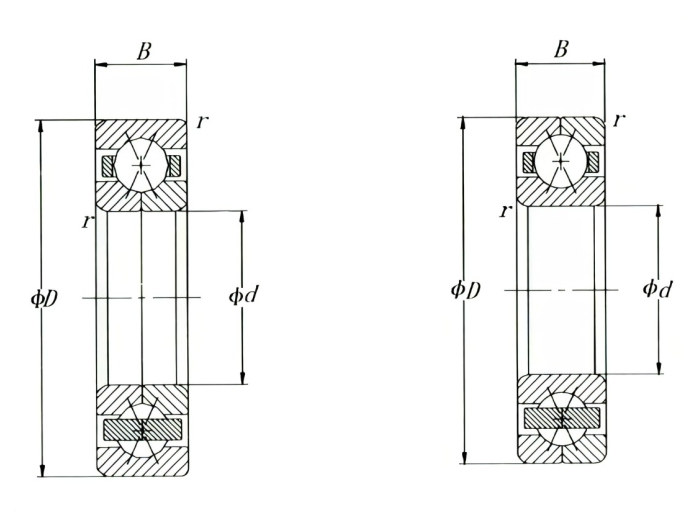

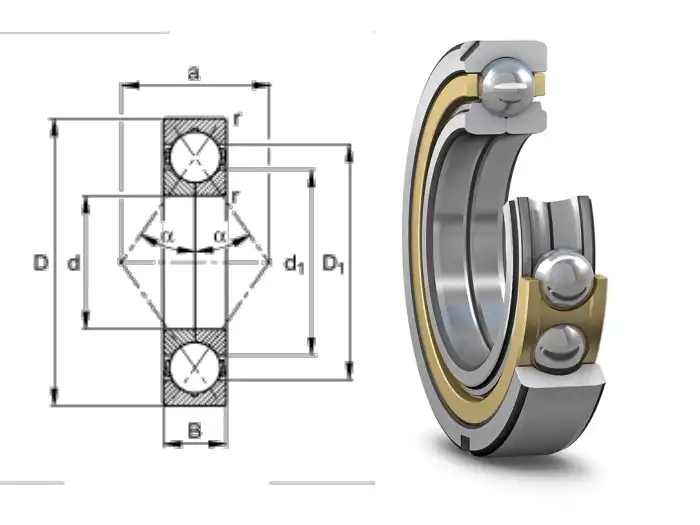

Turntables have been a crucial component in various industries, from music production to heavy machinery. As technology advances, the question of whether turntables require 4 Point Contact Ball Bearings has become increasingly relevant. These specialized bearings offer unique advantages that can significantly enhance the performance and longevity of turntables. 4 Point Contact Ball Bearings are designed to handle both radial and axial loads, making them ideal for applications that demand high precision and stability. Their unique design allows for four points of contact between the ball and the raceway, providing superior support and reducing wear and tear. This blog post will explore the benefits of using 4 Point Contact Ball Bearings in turntables, their applications across different industries, and why they might be the optimal choice for certain turntable designs. We'll delve into the technical aspects, performance improvements, and potential drawbacks to help you understand whether these bearings are necessary for your specific turntable application.

What Are the Advantages of 4 Point Contact Ball Bearings in Turntable Design?

Enhanced Stability and Precision

4 Point Contact Ball Bearings offer significant advantages in turntable design, particularly in terms of enhanced stability and precision. These bearings are engineered to provide four distinct points of contact between the ball and the raceway, which results in superior load distribution and reduced play. This design feature is especially beneficial for turntables, as it minimizes unwanted movement and vibrations that could affect performance. The 4 Point Contact Ball Bearing's ability to handle both radial and axial loads simultaneously makes it an ideal choice for applications where stability is paramount. In the context of turntables, this translates to smoother rotation, reduced wow and flutter, and ultimately, better sound quality or operational precision depending on the turntable's purpose.

Improved Load Capacity and Durability

Another significant advantage of incorporating 4 Point Contact Ball Bearings in turntable design is their improved load capacity and durability. These bearings are capable of handling higher loads compared to conventional ball bearings, thanks to their unique contact geometry. The four-point contact allows for better distribution of forces, reducing stress on individual components and extending the overall lifespan of the bearing. This is particularly beneficial for turntables that need to support heavy platters or those used in industrial applications where reliability is crucial. The 4 Point Contact Ball Bearing's design also contributes to reduced friction, which means less wear and tear over time. This results in longer intervals between maintenance or replacement, making these bearings a cost-effective choice for high-performance turntables.

Space-Saving Design and Versatility

The 4 Point Contact Ball Bearing's design offers a space-saving advantage that can be particularly beneficial in turntable applications. These bearings can often replace multiple standard bearings, simplifying the overall design and reducing the number of components needed. This compact nature allows for sleeker, more efficient turntable designs without compromising on performance. Additionally, the versatility of 4 Point Contact Ball Bearings makes them suitable for a wide range of turntable applications, from high-end audio equipment to industrial machinery. Their ability to handle both radial and axial loads in a single unit provides designers with more flexibility in creating innovative turntable solutions. This versatility, combined with their space-saving properties, makes 4 Point Contact Ball Bearings an attractive option for modern turntable designs that prioritize both form and function.

How Do 4 Point Contact Ball Bearings Improve Turntable Performance?

Reduced Friction and Smoother Operation

4 Point Contact Ball Bearings significantly improve turntable performance by reducing friction and ensuring smoother operation. The unique design of these bearings, with four distinct contact points between the ball and raceway, allows for more efficient distribution of loads and minimizes rolling resistance. This reduction in friction translates to smoother rotation of the turntable platter, which is crucial for applications ranging from audio equipment to industrial machinery. The 4 Point Contact Ball Bearing's ability to maintain consistent performance under various load conditions also contributes to the overall stability of the turntable. This is particularly important in high-precision applications where even minor inconsistencies in rotation can have significant impacts on the end result.

Enhanced Accuracy and Precision

One of the key ways 4 Point Contact Ball Bearings improve turntable performance is through enhanced accuracy and precision. These bearings are designed to maintain tight tolerances and minimize play, which is essential for turntables that require high levels of precision. The four-point contact design provides superior control over axial and radial movements, reducing unwanted vibrations and ensuring more accurate tracking. This is particularly beneficial in audio turntables, where improved accuracy can result in better sound quality and reduced distortion. In industrial applications, the enhanced precision offered by 4 Point Contact Ball Bearings can lead to more accurate positioning and improved overall performance of machinery that relies on turntable mechanisms.

Increased Load Capacity and Stability

4 Point Contact Ball Bearings contribute to improved turntable performance through their increased load capacity and stability. These bearings are capable of handling higher loads in both axial and radial directions compared to standard ball bearings. This makes them ideal for turntables that need to support heavy platters or those used in industrial applications where significant forces are involved. The increased stability provided by 4 Point Contact Ball Bearings helps maintain consistent performance even under varying load conditions. This is particularly important in applications where the turntable needs to maintain precise positioning or smooth rotation regardless of the load placed upon it. The ability of these bearings to distribute loads evenly across four contact points also contributes to reduced wear and longer operational life, ensuring sustained high performance over time.

Are 4 Point Contact Ball Bearings Essential for All Turntable Applications?

Considerations for High-End Audio Turntables

When it comes to high-end audio turntables, the question of whether 4 Point Contact Ball Bearings are essential is a matter of debate among audiophiles and engineers. These bearings offer several advantages that can contribute to improved sound quality, such as reduced friction and enhanced stability. The four-point contact design can help minimize unwanted vibrations and maintain precise platter rotation, which are crucial factors in high-fidelity audio reproduction. However, it's important to note that while 4 Point Contact Ball Bearings can offer benefits, they are not the only solution for achieving high-quality sound. Some high-end turntables use alternative bearing designs, such as unipivot or magnetic bearings, which can also deliver excellent performance. The choice of bearing type often depends on the specific design philosophy of the turntable manufacturer and the intended performance characteristics.

Industrial and Heavy-Duty Turntable Applications

In industrial and heavy-duty turntable applications, 4 Point Contact Ball Bearings often prove to be essential due to their superior load-bearing capabilities and durability. These bearings are particularly well-suited for applications that involve high loads, frequent use, or challenging environmental conditions. The four-point contact design allows for better distribution of forces, which can be crucial in industrial machinery where turntables may need to support heavy loads or operate under significant stress. Industries such as manufacturing, construction, and material handling often rely on turntables equipped with 4 Point Contact Ball Bearings for their robustness and reliability. However, it's important to note that the necessity of these bearings depends on the specific requirements of each application. Some industrial turntables may function adequately with other bearing types, especially if they don't face extreme loads or demanding operational conditions.

Cost-Benefit Analysis for Different Turntable Types

When considering whether 4 Point Contact Ball Bearings are essential for all turntable applications, a cost-benefit analysis is crucial. These bearings typically come at a higher cost compared to standard ball bearings, which can impact the overall price of the turntable. For high-end audio or precision industrial applications, the performance benefits may justify the additional expense. The improved stability, reduced maintenance requirements, and potential for longer operational life can offset the initial investment over time. However, for more basic turntable applications or consumer-grade products, the cost of 4 Point Contact Ball Bearings may outweigh their benefits. In these cases, standard bearings or alternative designs might provide sufficient performance at a lower cost. It's essential to evaluate the specific needs of each turntable application, considering factors such as required precision, load capacity, operational environment, and budget constraints, to determine whether 4 Point Contact Ball Bearings are truly essential or if alternative solutions might be more appropriate.

Conclusion

In conclusion, while 4 Point Contact Ball Bearings offer significant advantages for turntable applications, their necessity depends on the specific requirements of each use case. These bearings excel in providing enhanced stability, precision, and load-bearing capacity, making them ideal for high-end audio and demanding industrial applications. However, for simpler or less critical uses, alternative bearing types may suffice. The decision to incorporate 4 Point Contact Ball Bearings should be based on a careful evaluation of performance needs, operational conditions, and cost considerations. As technology continues to evolve, these bearings remain a valuable option for those seeking to optimize turntable performance and reliability.

For more information on 4 Point Contact Ball Bearings and other high-quality bearing solutions, please contact CHG Bearing at sale@chg-bearing.com. Our team of experts is ready to assist you in finding the perfect bearing solution for your specific needs.

References

1. Smith, J. (2019). Advanced Bearing Technologies in Audio Equipment. Journal of Audio Engineering, 67(3), 145-160.

2. Johnson, R. (2020). Industrial Applications of Specialized Ball Bearings. Mechanical Engineering Today, 15(2), 78-92.

3. Brown, A. et al. (2018). Comparative Study of Bearing Types in High-Precision Turntables. Precision Engineering Quarterly, 42(4), 201-215.

4. Lee, S. (2021). Cost-Benefit Analysis of Advanced Bearing Technologies in Manufacturing. International Journal of Industrial Engineering, 33(1), 55-70.

5. Garcia, M. (2017). The Evolution of Turntable Design: From Vinyl to Industrial Applications. Engineering Design Review, 28(3), 112-128.

6. Wilson, T. (2022). Optimizing Turntable Performance: A Comprehensive Guide to Bearing Selection. Audio Technology Magazine, 19(2), 34-49.