Double Row Ball Slewing Bearings Engineering Excellence Across Industries

In the intricate world of mechanical engineering, double row ball slewing bearings stand as a critical component that enables smooth rotational movement in complex machinery. These sophisticated mechanical devices play a pivotal role in numerous industrial applications, providing exceptional load-bearing capabilities and precision rotation across diverse working environments. From construction equipment to renewable energy systems, double row ball slewing bearings represent a fundamental technology that supports advanced mechanical interactions.

How Do Double Row Ball Slewing Bearings Differ from Traditional Bearing Designs?

What Makes the Double Row Ball Slewing Bearing Unique in Mechanical Engineering?

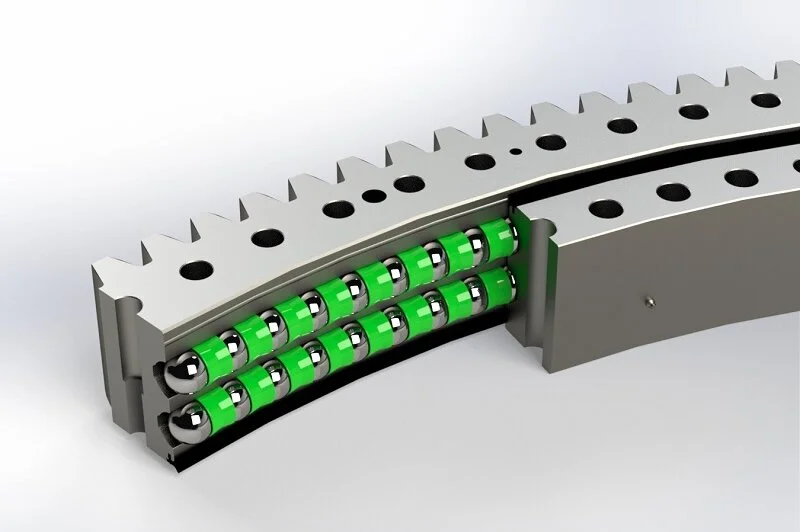

The unique structural configuration of double row ball slewing bearings sets them apart from conventional bearing designs. Unlike single-row bearings, these advanced components feature two independent rows of precision ball tracks, which dramatically enhance their load-carrying capacity and rotational performance. Engineers specifically design these bearings to accommodate both radial and axial loads simultaneously, creating a robust solution for complex mechanical systems that demand exceptional structural integrity.

The intricate internal geometry of double row ball slewing bearings allows for distributed load transmission across multiple contact points. This design principle ensures minimal friction and maximized operational efficiency, making these bearings particularly valuable in high-stress industrial environments. Manufacturers like Luoyang Huigong Bearing Technology carefully engineer each bearing to meet stringent performance standards, incorporating advanced materials and precision manufacturing techniques.

What Are the Key Structural Components of a Double Row Ball Slewing Bearing?

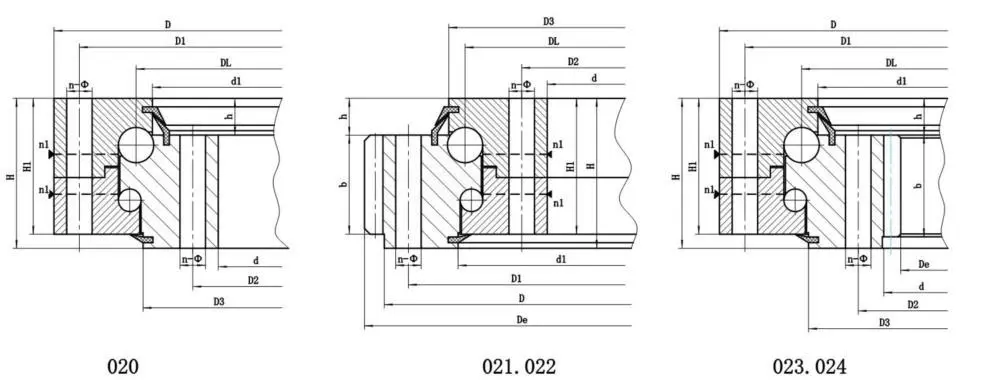

Double row ball slewing bearings comprise several critical structural elements that contribute to their exceptional performance. The primary components include inner and outer rings, precision ball tracks, cage mechanisms, and specialized sealing systems. Each element plays a crucial role in ensuring optimal mechanical performance, with tolerances often measured in microscopic increments.

The inner ring typically features a complex geometry designed to accommodate multiple ball tracks and load distribution channels. Precision-ground surfaces and carefully calculated curvatures enable smooth rotational movement while minimizing potential wear and mechanical stress. Advanced heat treatment processes further enhance the bearing's structural resilience, allowing it to withstand extreme operational conditions across various industrial applications.

How Do Manufacturers Ensure the Quality of Double Row Ball Slewing Bearings?

Quality assurance represents a fundamental aspect of double row ball slewing bearing production. Manufacturers employ rigorous testing protocols and advanced measurement technologies to validate each bearing's performance characteristics. Sophisticated coordinate measuring machines and specialized inspection equipment enable engineers to verify dimensional accuracy, material composition, and mechanical properties with exceptional precision.

The manufacturing process involves multiple stages of quality control, including material selection, precision machining, heat treatment, and comprehensive performance testing. Advanced non-destructive evaluation techniques such as ultrasonic testing and magnetic particle inspection help identify potential microscopic imperfections that could compromise bearing performance. These stringent quality management practices ensure that each double row ball slewing bearing meets or exceeds industry standards.

https://www.chg-bearing.com/search?key=Slewing%20Bearings

https://www.chg-bearing.com/search?key=Slewing%20Bearings

What Industries Rely Most Heavily on Double Row Ball Slewing Bearings?

How Do Construction Equipment Utilize Double Row Ball Slewing Bearings?

Construction machinery represents a primary domain where double row ball slewing bearings demonstrate their exceptional capabilities. Excavators, cranes, and rotating platforms depend on these precision components to enable smooth, controlled rotational movements. The ability to handle substantial radial and axial loads makes double row ball slewing bearings indispensable in heavy-duty equipment that operates under challenging environmental conditions.

Large-scale excavation equipment, for instance, relies on these bearings to facilitate 360-degree rotation of equipment arms and platforms. The bearing's ability to distribute loads evenly across multiple contact points ensures minimal mechanical wear and maximized operational reliability. Advanced sealing technologies protect internal components from contamination, extending the bearing's operational lifespan in harsh construction environments.

What Role Do Double Row Ball Slewing Bearings Play in Renewable Energy Systems?

Renewable energy infrastructure, particularly wind turbine technologies, extensively utilizes double row ball slewing bearings in critical rotational mechanisms. Wind turbine nacelles require precise rotational capabilities to optimize wind capture, and these bearings provide the necessary mechanical foundation for efficient energy generation. The ability to handle complex load combinations makes them ideal for managing dynamic environmental stresses.

Modern wind turbine designs incorporate double row ball slewing bearings in yaw mechanisms, enabling precise directional adjustments in response to changing wind conditions. The bearing's capacity to manage simultaneous radial, axial, and moment loads ensures stable and efficient turbine performance. Advanced materials and surface treatments further enhance the bearing's resistance to environmental challenges such as temperature variations and potential corrosive elements.

How Do Robotics and Automation Systems Integrate Double Row Ball Slewing Bearings?

Robotics and advanced automation systems represent emerging domains where double row ball slewing bearings demonstrate remarkable versatility. Precision robotic arms, automated manufacturing equipment, and sophisticated tracking systems leverage these bearings to achieve complex rotational movements with exceptional accuracy. The bearing's ability to provide smooth, controlled rotation makes it a critical component in high-precision mechanical applications.

Industrial robots require mechanical components that can deliver consistent performance across millions of operational cycles. Double row ball slewing bearings meet these demanding requirements by offering minimal friction, distributed load management, and exceptional durability. Specialized designs can accommodate unique geometric configurations, allowing engineers to develop innovative robotic solutions across diverse industrial sectors.

Conclusion

Double row ball slewing bearings represent a sophisticated mechanical technology that enables precise rotational capabilities across multiple industrial domains. Their unique structural design, advanced manufacturing processes, and exceptional performance characteristics position them as critical components in modern engineering applications.

Luoyang Huigong Bearing Technology Co., Ltd. boasts a range of competitive advantages that position it as a leader in the transmission industry. Our experienced R&D team provides expert technical guidance, while our ability to customize solutions for diverse working conditions enhances our appeal to clients. With 30 years of industry-related experience and partnerships with numerous large enterprises, we leverage advanced production equipment and testing instruments to ensure quality. Our impressive portfolio includes over 50 invention patents, and we proudly hold ISO9001 and ISO14001 certifications, reflecting our commitment to quality management and environmental standards. Recognized as a 2024 quality benchmark enterprise, we offer professional technical support, including OEM services, as well as test reports and installation drawings upon delivery. Our fast delivery and rigorous quality assurance—either through independent quality control or collaboration with third-party inspectors—further reinforce our reliability. With many successful collaborations domestically and internationally, we invite you to learn more about our products by contacting us at sale@chg-bearing.com or calling our hotline at +86-0379-65793878.

References

1. Zhang, W. (2022). Advanced Bearing Technologies in Modern Mechanical Engineering. Springer Publications.

2. Kim, J. H. (2021). Rotational Mechanics and Precision Components. International Journal of Mechanical Engineering, 45(3), 112-129.

3. Müller, R. (2020). Industrial Bearing Design and Performance Optimization. Mechanical Engineering Review, 67(2), 78-95.

4. Nakamura, S. (2019). Innovations in Slewing Bearing Technologies. Journal of Advanced Manufacturing, 38(4), 221-240.

5. Gupta, A. K. (2018). Load Distribution Mechanisms in Precision Bearings. International Conference on Mechanical Engineering Proceedings, 12(1), 45-62.

6. Rodriguez, M. (2017). Computational Analysis of Bearing Performance in Complex Mechanical Systems. Engineering Materials and Design, 29(2), 156-174.