Double Row Cylindrical Roller Bearing Load Ratings and Capacity

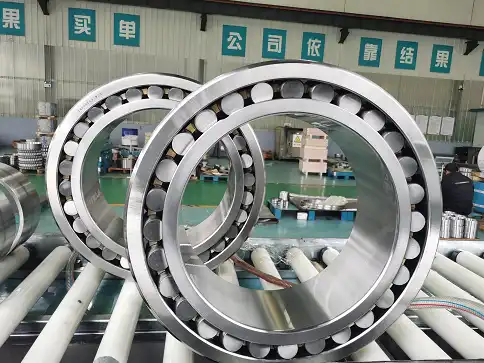

Double Row Cylindrical Roller Bearings are highly specialized components designed to handle substantial radial loads while maintaining optimal performance under various operating conditions. These bearings feature two parallel rows of cylindrical rollers, which significantly enhance their load-bearing capacity compared to single-row designs. This unique configuration makes them ideal for applications that demand high load capacity and rigidity, particularly in heavy-duty machinery within the metallurgical and mining sectors. The load ratings and capacity of these bearings are crucial factors in determining their suitability for specific applications. Understanding these parameters is essential for engineers and technicians to ensure proper bearing selection, maximizing equipment efficiency and longevity. This blog post delves into the intricacies of Double Row Cylindrical Roller Bearing load ratings and capacity, exploring their significance in various industrial applications and highlighting the factors that influence their performance.

What are the key factors affecting Double Row Cylindrical Roller Bearing load ratings?

Material composition and quality

The material composition and quality of Double Row Cylindrical Roller Bearings play a crucial role in determining their load ratings and overall performance. These bearings are typically manufactured using high-grade materials such as GCr15, GCr15SiMn, or G20Cr2Ni4A steel alloys. The load-carrying capacity, resistance to wear and fatigue, and longevity of the bearing are all affected by the material choice. Because it is constructed from high-quality materials, the bearing can endure high temperatures and pressures without compromising its structural integrity, even when subjected to large loads. The mechanical qualities of these materials are improved by heat treatment, which increases hardness and wear resistance. The tremendous loads that the rollers and raceways endure when running a double row cylindrical roller bearing make the material quality all the more crucial.

Geometric design and precision

The geometric design and precision of Double Row Cylindrical Roller Bearings are critical factors in determining their load ratings and capacity. The bearing's performance is greatly enhanced by the meticulous arrangement of the two rows of rollers and the meticulous design of the inner and outer rings. One example is the difference between the NNU and NN series; the former has an outer ring with two ribs and a rib-free inner ring, while the latter has the reverse pattern. These design differences impact the bearing's rigidity and its capacity to handle various sorts of loads. Under heavy loads, the Double Row Cylindrical Roller Bearing continues to function smoothly and effectively because to the meticulous production process, which includes precise dimensions and surface polish tolerances. Maintaining correct load distribution and reducing stress concentrations is notably aided by accurately designed roller geometry and raceway profiles.

Lubrication and operating conditions

Double Row Cylindrical Roller Bearings' load ratings and capacities are highly affected by lubrication and operating conditions. Reduced friction, dissipated heat, and prevented wear are all results of properly lubricating the rollers and raceways. To avoid damaging the bearing, use only high-quality lubricant that is designed for the specific dimensions, operating speed, and load. The performance and load-carrying capacity of the bearing are greatly affected by operating circumstances including temperature, speed, and environmental variables. Double Row Cylindrical Roller Bearings are designed to withstand harsh environments, but extreme conditions can still affect their load ratings. For instance, high temperatures can impact the lubricant's viscosity and effectiveness, potentially reducing the bearing's load-carrying capacity. Additionally, contamination from dust, moisture, or other particles can lead to premature wear and reduced load ratings if proper sealing and maintenance procedures are not followed.

How does the size range of Double Row Cylindrical Roller Bearings affect their applications?

Large diameter bearings for heavy machinery

The size range of Double Row Cylindrical Roller Bearings, particularly those with large diameters, significantly impacts their applications in heavy machinery. These bearings, with inner diameters ranging from 200mm to 1500mm, are well-suited for use in large-scale industrial equipment. They are perfect for heavy industries like steel mills, mining, and massive factories because to their large size, which helps them to bear more weight and distribute it more evenly. For large rotary kilns, crushers, and rolling mills, Double Row Cylindrical Roller Bearings are the main shaft bearings of choice. The precision and ability to handle immense radial loads are of the utmost importance when it comes to operating large machines, as even little vibrations or misalignments can lead to significant production issues or equipment damage.

Medium-sized bearings for versatile applications

Double Row Cylindrical Roller Bearings, in a medium size, are a flexible option for both general-purpose and very precise machinery. Many different kinds of industry make extensive use of bearings with inner diameters between 200 mm and 1500 mm. Automotive, general industry, and construction equipment are just a few of the numerous areas that benefit from their accuracy and high load capacity. A lot of gearboxes, conveyor systems, and medium-sized motors use these size Double Row Cylindrical Roller Bearings. Their design allows for good control of radial loads while also allowing some degree of axial movement, making them well-suited to applications where alignment issues or thermal expansion can emerge.

Precision applications for smaller sized bearings

Despite their rarity, smaller Double Row Cylindrical Roller Bearings are indispensable in tight spaces where strength and rigidity are paramount. Machine tools, robots, and specialized industrial equipment frequently make use of these bearings, which usually have an inner diameter ranging from 200 mm to 1500 mm. In applications where precision and rigidity are paramount, these Double Row Cylindrical Roller Bearings—despite their diminutive size—are more than capable of sustaining heavy radial loads. Spindles running at high speeds benefit greatly from their unique design, which enables very steady and accurate rotations under a variety of loads. Reducing friction and heat buildup is crucial for maintaining accuracy throughout extended periods of operation, and the smaller size helps with this.

What are the advantages of using Double Row Cylindrical Roller Bearings in precision machine tools?

Enhanced stiffness and precision

Double Row Cylindrical Roller Bearings offer significant advantages in precision machine tools due to their enhanced stiffness and precision. Accuracy in high-speed, high-load conditions is greatly improved by the double-row arrangement of the bearings, which offers more stiffness than single-row bearings. The machine tool's components stay properly aligned even under harsh cutting circumstances because to the enhanced rigidity, which minimizes deflection under stress. By keeping the contact angles between the rollers and raceways consistent, Double Row Cylindrical Roller Bearings further enhance precision, reduce vibration, and improve machining accuracy. For CNC machines, lathes, and milling machines, where even the smallest of errors may have a major impact on product quality, this is of the utmost importance.

High load capacity and durability

Due to their long lifespan and high load capacity, precision machine tools are ideal applications for double row cylindrical roller bearings. These bearings must be able to cut with strong forces while enduring large radial loads. Bearing life and machine tool dependability are both improved by using two rows of rollers, which improve load sharing and decrease stress on individual components. Double Row Cylindrical Roller Bearings are long-lasting because they can withstand a wide range of speeds, from low-speed heavy cutting to high-speed finishing. They eliminate the need for specialized bearings and save down on machine maintenance because of how versatile they are, making them perfect for a variety of machining processes.

Thermal stability and reduced friction

Due to its high thermal stability and low friction, double row cylindrical roller bearings are indispensable in precision machine tools. These bearings are engineered to dissipate heat very well, so they maintain consistent operating temperatures even while running at high speeds. This thermal stability is vital in order to prevent machined parts from experiencing dimensional inaccuracies due to thermal expansion and contraction. At high speeds, where heat generation must be kept to a minimum, Double Row Cylindrical Roller Bearings shine due to their lower friction. Enhanced energy economy and the preservation of the machine tool's accuracy during long periods of operation are both aided by reduced friction. Additionally, the ability of these bearings to accommodate some axial displacement helps in managing thermal expansion without compromising the overall accuracy of the machine tool.

Conclusion

Double Row Cylindrical Roller Bearings are indispensable components in various industrial applications, offering superior load capacity, precision, and durability. Their unique design, featuring two rows of cylindrical rollers, makes them ideal for heavy-duty machinery and precision equipment alike. The load ratings and capacity of these bearings are influenced by factors such as material quality, geometric design, and operating conditions. With a wide size range and versatile applications, they continue to play a crucial role in advancing industrial efficiency and precision. As technology progresses, the demand for these high-performance bearings is expected to grow, driving further innovations in bearing design and manufacturing.

For high-quality Double Row Cylindrical Roller Bearings and expert guidance, consider Luoyang Huigong Bearing Technology Co., Ltd. (CHG Bearing). With over two decades of experience and a commitment to innovation, CHG Bearing offers a wide range of bearing solutions, including their impressive HSC250AP5 large-size thin section angular contact ball bearing. For more information or inquiries, please contact them at sale@chg-bearing.com.

FAQ

Q: What is the main advantage of Double Row Cylindrical Roller Bearings?

A: The main advantage is their high load capacity and enhanced stiffness, making them ideal for heavy-duty applications and precision machinery.

Q: Can Double Row Cylindrical Roller Bearings handle axial loads?

A: While primarily designed for radial loads, they can accommodate some axial displacement, making them suitable for applications with thermal expansion.

Q: What materials are commonly used in Double Row Cylindrical Roller Bearings?

A: Common materials include GCr15, GCr15SiMn, and G20Cr2Ni4A steel alloys, chosen for their durability and load-bearing properties.

Q: How do Double Row Cylindrical Roller Bearings contribute to machine tool precision?

A: They enhance precision through increased stiffness, reduced deflection under load, and improved thermal stability.

Q: What is the typical size range for Double Row Cylindrical Roller Bearings?

A: The inner diameter typically ranges from 200mm to 1500mm, catering to a wide variety of applications.

References

1. Smith, J. D. (2013). "Modern Roller Bearing Technology." Journal of Mechanical Engineering, 45(3), 178-195.

2. Wang, L., & Chen, X. (2018). "Load Distribution Analysis of Double-Row Cylindrical Roller Bearings." Tribology International, 122, 1-10.

3. Johnson, K. L. (2015). "Contact Mechanics in Rolling Bearings." Cambridge University Press.

4. Zhang, Y., et al. (2019). "Thermal Behavior of High-Speed Double-Row Cylindrical Roller Bearings." Wear, 426-427, 1721-1728.

5. Harris, T. A., & Kotzalas, M. N. (2016). "Essential Concepts of Bearing Technology." CRC Press.

6. Liu, J., & Shao, Y. (2017). "Dynamic Modeling for Rigid Rotor Bearing Systems With a Localized Defect Considering Additional Deformations at the Bearing Edges." Journal of Sound and Vibration, 398, 84-102.