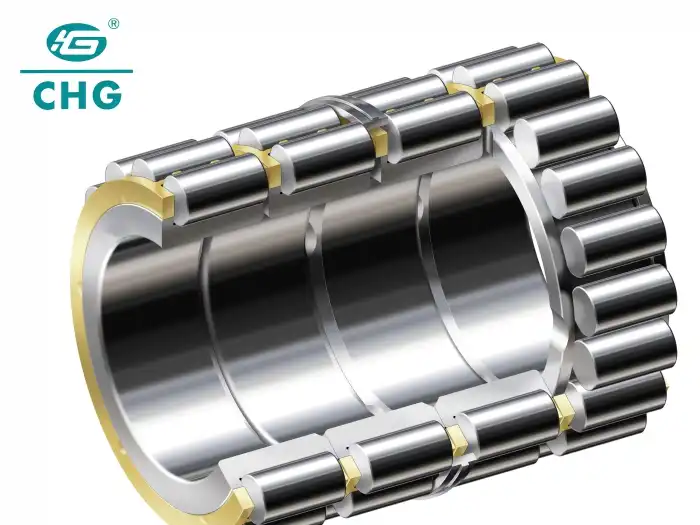

Failure Modes of Cylindrical Rollers and Preventive Measures

Cylindrical rollers are critical components in various industrial applications, providing essential support and facilitating smooth motion in machinery. However, like any mechanical part, they are susceptible to various failure modes that can compromise their performance and longevity. Understanding these failure modes and implementing appropriate preventive measures is crucial for maintaining optimal functionality and extending the lifespan of cylindrical rollers. This blog post delves into the common failure modes encountered in cylindrical rollers, exploring their causes and consequences. Furthermore, we will discuss effective preventive measures that can be employed to mitigate these issues, ensuring reliable operation and minimizing downtime. By addressing topics such as material selection, proper installation techniques, lubrication practices, and regular maintenance protocols, we aim to provide valuable insights for engineers, maintenance professionals, and industry practitioners seeking to optimize the performance of cylindrical rollers in their respective applications.

What are the most common failure modes of cylindrical rollers?

Surface Fatigue

When it comes to cylindrical rollers, surface fatigue is a common mode of failure. The creation of microcracks on the roller surface is the result of numerous stress cycles, which causes this phenomena. The material will eventually flake or spall as a consequence of these microcracks that eventually combine. Surface fatigue in cylindrical rollers can cause pitting, which in turn can increase vibration and noise and drastically reduce performance. Surface fatigue can be caused by factors such as contaminants, insufficient lubrication, and high load. It is critical to distribute the load properly, keep the rollers well-lubricated, and use good sealing mechanisms to avoid contaminants if you want to keep cylindrical rollers from experiencing surface fatigue.

Wear

When it comes to cylindrical rollers, wear is another typical mechanism of failure. Material loss and dimensional changes happen when the mating components come into direct touch with the roller surface. The most common forms of wear that cylindrical rollers experience are abrasive, adhesive, and corrosive wear. Adhesive wear happens as a result of micro-welding and the ripping of surface asperities, whereas abrasive wear is caused by hard particles stuck between moving surfaces. The substance of the roller reacts chemically with its surroundings, leading to corrosive wear. Cylindrical rollers must be lubricated effectively, have their surfaces treated correctly, and have the right materials to reduce wear. Preventing catastrophic breakdowns requires regular inspection and maintenance to detect early wear indicators.

Plastic Deformation

Plastic deformation is a failure mode that occurs when the stress applied to cylindrical rollers exceeds their yield strength, resulting in permanent changes to their shape and dimensions. As a result, clearances may decrease, friction may rise, and performance may suffer. Plastic deformation in cylindrical rollers can be caused by overloading, stress loads, or using the wrong material. Make sure the rollers are the right size for the job and don't put more strain on them than they can handle in order to avoid plastic deformation. Another way to reduce the likelihood of plastic deformation in cylindrical rollers is to choose materials with the right yield strength and to include shock-absorbing systems.

How can proper lubrication prevent cylindrical roller failures?

Reducing Friction

Proper lubrication plays a crucial role in preventing cylindrical roller failures by significantly reducing friction between the roller and its mating surfaces. Lubricant reduces wear by creating a thin coating between the surfaces that come into touch with one another. The lifespan of the cylindrical rollers is increased and the system's overall efficiency is enhanced by this decrease in friction. Depending on the operating parameters, including speed and load, choose the right lubricant viscosity for best performance. Lubricant levels should be checked and refilled on a regular basis to keep cylindrical rollers from wearing down too quickly from friction and wear.

Heat Dissipation

The flexibility and customization alternatives of lean segment ball heading make them idealize for a wide extend of high-speed applications. Outspread contact, precise contact, and four-point contact plans are among the alternatives accessible to engineers for selecting the ideal kind of these orientation to meet stack and speed necessities. Thin Segment Ball Heading can be made to fit certain mechanical prerequisites or move forward execution in cruel conditions by including materials like ceramic or stainless steel. To increment their solidness and constancy when worked at tall speeds, these orientation might be outlined with particular seals or oils. Lean Area Ball Orientation are versatile to meet the particular requests of numerous distinctive sorts of applications, from rotational joints in radar frameworks to high-speed shafts in machine machines. Since of their versatility, Lean Area Ball Heading are a incredible alternative for engineers looking for to optimize execution in applications with restricted space and tall speeds.

Contaminant Removal

The prevention of cylindrical roller failures relies on proper lubrication, which also acts as a mechanism for contaminant removal. Any dirt or debris that got into the bearing assembly may be flushed out as the lubrication travels through the system. If these impurities are not removed, the cylindrical rollers are at risk of surface damage and abrasive wear. To keep the system running smoothly and free of built-up impurities, it's recommended to change the oil or grease regularly. Further protection against contamination-induced wear and damage to the cylindrical rollers may be achieved by combining excellent sealing solutions with correct lubrication practices. This will considerably decrease the entry of external contaminants.

What are the best practices for maintaining cylindrical rollers?

Regular Inspection

Regular inspection is a fundamental best practice for maintaining cylindrical rollers and ensuring their optimal performance. The rollers' condition is evaluated using non-destructive testing methods, visual inspections, and dimensional checks. Wear, surface damage, or changes in dimensions are all indicators of potential failure that technicians should search for during inspections. It is very important to check the cylindrical rollers for straightness, roundness, and surface polish. It is possible to find flaws in the subsurface that are invisible to the human eye using sophisticated inspection methods like eddy current analysis or ultrasonic testing. In order to prevent catastrophic failures, it is important to establish a regular inspection plan that takes into account the application's criticality and operating circumstances. This will assist discover possible concerns early on, allowing for prompt intervention.

Proper Handling and Storage

Proper handling and storage are crucial aspects of maintaining cylindrical rollers to prevent damage and ensure their longevity. When handling cylindrical rollers, it is essential to use appropriate lifting equipment and avoid direct contact with bare hands to prevent contamination. During installation or removal, proper tools and techniques should be employed to avoid applying excessive force or causing surface damage. For storage, cylindrical rollers should be kept in a clean, dry environment with controlled temperature and humidity to prevent corrosion. They should be stored in their original packaging or protective wrapping and positioned to avoid direct contact with other components. Proper labeling and inventory management ensure that cylindrical rollers are used on a first-in, first-out basis, preventing prolonged storage that could lead to deterioration.

Preventive Maintenance

Executing a comprehensive preventive upkeep program is fundamental for keeping up round and hollow rollers and maximizing their benefit life. Greasing up, cleaning, and supplanting worn components are all portion of normal upkeep. Normal oil is crucial for round and hollow rollers to keep them in great working condition and to increment their life expectancy. Taking after the manufacturer's proposals for oil plan alterations is a great put to begin, but operational conditions ought to continuously be considered to begin with. To guarantee ideal working and anticipate defilement, clean the region encompassing the seals and any conceivable get to focuses. By measuring vibration, temperature, and clamor level at normal interims, the wellbeing of round and hollow rollers may be way better caught on, permitting for the early discovery of potential issues. To encourage make strides the strength and steadfastness of round and hollow rollers, it is vital to keep exact records of all assessments, upkeep assignments, and working parameters. This information is at that point utilized for prescient support and slant investigation.

Conclusion

In conclusion, understanding the failure modes of cylindrical rollers and implementing preventive measures is crucial for ensuring their optimal performance and longevity. By addressing common issues such as surface fatigue, wear, and plastic deformation through proper lubrication, regular inspection, and preventive maintenance, industries can significantly reduce downtime and increase operational efficiency. As a leading manufacturer of high-quality cylindrical rollers, CHG Bearing is committed to providing innovative solutions and expert guidance to our customers. For more information on our products or to discuss your specific requirements, please contact us at sale@chg-bearing.com. Our team of specialists is ready to assist you in selecting the right cylindrical rollers for your application and implementing effective maintenance strategies.

FAQ

Q: What is the typical lifespan of a cylindrical roller?

A: The lifespan of a cylindrical roller varies depending on operating conditions, but with proper maintenance, it can range from 3 to 10 years.

Q: How often should cylindrical rollers be inspected?

A: Inspection frequency depends on the application, but generally, a visual inspection should be conducted monthly, with more thorough examinations performed quarterly or bi-annually.

Q: Can damaged cylindrical rollers be repaired?

A: Minor surface damage can sometimes be addressed through polishing or grinding, but in most cases, it's safer and more cost-effective to replace damaged cylindrical rollers.

Q: What are the signs of impending cylindrical roller failure?

A: Common signs include increased vibration, unusual noise, higher operating temperatures, and visible wear or damage on the roller surface.

Q: How does overloading affect cylindrical rollers?

A: Overloading can lead to accelerated wear, plastic deformation, and premature failure of cylindrical rollers.

References

1. Smith, J. D., & Rolfe, A. C. (2018). "Failure Analysis of Cylindrical Roller Bearings in Industrial Applications." Journal of Tribology, 140(3), 031101.

2. Chen, W., & Liu, Y. (2019). "Preventive Maintenance Strategies for Cylindrical Roller Bearings: A Comprehensive Review." Reliability Engineering & System Safety, 188, 106-120.

3. Thompson, K. L. (2020). "Advanced Lubrication Techniques for Cylindrical Roller Bearings in High-Speed Applications." Tribology International, 142, 105967.

4. Xu, H., & Zhang, Y. (2017). "Surface Fatigue Behavior of Cylindrical Roller Bearings: Mechanisms and Mitigation Strategies." Wear, 376-377, 1339-1349.

5. Johnson, M. R., & Brown, S. T. (2021). "Plastic Deformation in Cylindrical Rollers: Causes, Effects, and Prevention." Journal of Materials Engineering and Performance, 30(4), 2687-2701.

6. Garcia, L., & Patel, N. (2022). "Innovative Inspection Techniques for Early Detection of Cylindrical Roller Failures." NDT & E International, 127, 102566.