How Are Cylindrical Roller Bearings Classified by Number of Rows?

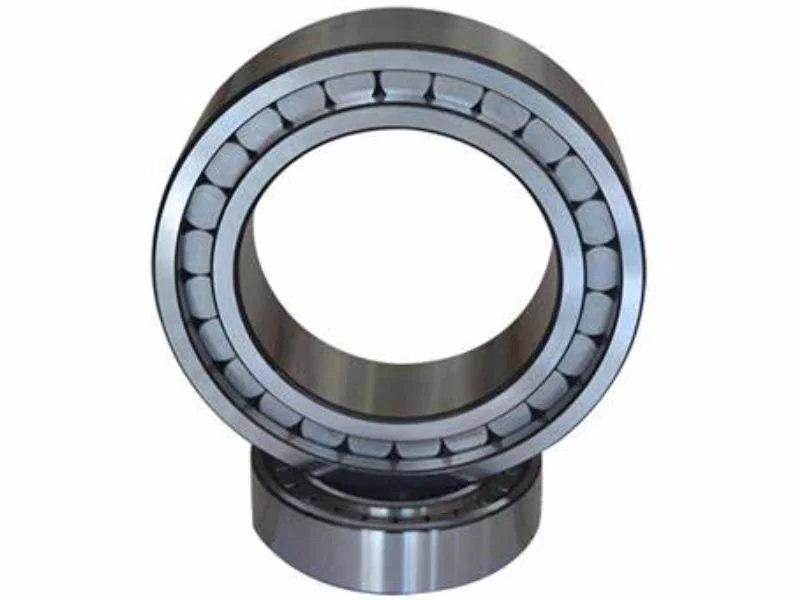

Cylindrical roller bearings are essential components in various industrial applications, known for their high load-carrying capacity and ability to operate efficiently in high-speed environments. These bearings are classified based on several factors, with the number of rows being a crucial characteristic that determines their performance and suitability for different applications. Understanding how cylindrical roller bearings are classified by the number of rows is vital for engineers, designers, and maintenance professionals to select the most appropriate bearing for their specific needs. This classification system not only affects the bearing's load-carrying capacity but also influences its speed capabilities, alignment properties, and overall performance in different operating conditions. In this comprehensive guide, we will explore the various classifications of cylindrical roller bearings based on the number of rows, delving into their unique features, advantages, and typical applications across industries.

What Are the Main Types of Single-Row Cylindrical Roller Bearings?

NU Series Cylindrical Roller Bearings

NU series cylindrical roller bearings are a popular choice in many industrial applications. These bearings feature two ribs on the outer ring and no ribs on the inner ring, allowing for axial displacement of the shaft relative to the housing in both directions. The design of NU series bearings makes them ideal for applications where thermal expansion of the shaft needs to be accommodated. They excel in handling heavy radial loads and are commonly used in electric motors, gearboxes, and pumps. The absence of ribs on the inner ring allows for easier mounting and dismounting, which is particularly beneficial in maintenance-intensive environments. NU series cylindrical roller bearings are known for their high-speed capabilities and are often preferred in applications where rotational speeds are a critical factor.

NJ Series Cylindrical Roller Bearings

NJ series cylindrical roller bearings are characterized by two ribs on the outer ring and one rib on the inner ring. This configuration allows them to carry axial loads in one direction, making them suitable for applications where moderate axial forces are present alongside high radial loads. The design of NJ series bearings provides enhanced stability and guidance for the rollers, resulting in improved performance under combined loading conditions. These bearings are frequently used in heavy machinery, such as rolling mills, paper machines, and construction equipment. The ability to handle both radial and axial loads makes NJ series cylindrical roller bearings a versatile option for designers looking to simplify bearing arrangements in complex machinery.

N Series Cylindrical Roller Bearings

N series cylindrical roller bearings feature two ribs on the inner ring and no ribs on the outer ring. This design allows for axial displacement of the housing relative to the shaft in both directions. N series bearings are particularly useful in applications where the outer ring needs to be a tight fit in the housing, while still allowing for thermal expansion of the shaft. They are commonly employed in large electric motors, generators, and turbines where precise alignment and the ability to accommodate thermal growth are crucial. The absence of ribs on the outer ring also facilitates easier mounting and dismounting of the bearing from the housing, which can be advantageous in certain maintenance scenarios.

How Do Double-Row Cylindrical Roller Bearings Differ from Single-Row Designs?

Increased Load Capacity

Double-row cylindrical roller bearings offer significantly higher load capacity compared to their single-row counterparts. This increased capacity is due to the presence of two rows of rollers, effectively doubling the contact area between the rolling elements and the raceways. As a result, these bearings can handle much heavier radial loads, making them ideal for applications in heavy industries such as mining, steel production, and large-scale manufacturing equipment. The enhanced load distribution across two rows also contributes to reduced stress on individual rollers and raceways, potentially extending the bearing's operational life. In scenarios where space is limited but load requirements are high, double-row cylindrical roller bearings provide an excellent solution without necessitating a significant increase in bearing size.

Enhanced Stability

Double-row cylindrical roller bearings offer superior stability compared to single-row designs, particularly in applications involving long shafts or where misalignment is a concern. The two rows of rollers provide better support and guidance for the shaft, reducing the likelihood of shaft deflection and maintaining proper alignment even under heavy loads or dynamic operating conditions. This enhanced stability is particularly beneficial in large rotating machinery, such as paper machines, printing presses, and wind turbine gearboxes, where maintaining precise shaft positioning is crucial for optimal performance and longevity. The improved stability also contributes to reduced vibration levels, which can lead to quieter operation and less wear on associated components.

Suitability for High-Speed Applications

While double-row cylindrical roller bearings are known for their high load capacity, they are also well-suited for high-speed applications. The design of these bearings allows for effective heat dissipation and lubrication distribution, which are critical factors in high-speed operations. The presence of two rows of rollers helps to distribute the centrifugal forces more evenly, reducing the stress on individual components and allowing for higher rotational speeds compared to some other bearing types. This makes double-row cylindrical roller bearings an excellent choice for applications such as high-speed industrial fans, turbomachinery, and certain types of machine tool spindles where both high loads and high speeds are encountered simultaneously.

What Are the Advantages of Multi-Row Cylindrical Roller Bearings?

Exceptional Load-Bearing Capacity

Multi-row cylindrical roller bearings, which include designs with three or more rows of rollers, offer exceptional load-bearing capacity that surpasses even that of double-row bearings. This extraordinary capacity makes them ideal for extreme heavy-duty applications where massive radial loads need to be supported. Industries such as steel rolling mills, large mining equipment, and offshore drilling platforms often rely on multi-row cylindrical roller bearings to handle the immense forces encountered in their operations. The distribution of load across multiple rows of rollers not only allows for higher load ratings but also contributes to more even stress distribution within the bearing, potentially leading to extended service life under severe operating conditions.

Compact Design for High Load Applications

One of the key advantages of multi-row cylindrical roller bearings is their ability to handle extremely high loads in a relatively compact design. By incorporating multiple rows of rollers within a single bearing assembly, these bearings can achieve load capacities that would typically require much larger single-row or double-row bearings. This compact design is particularly beneficial in applications where space is at a premium but load requirements are high. For example, in the gearboxes of large wind turbines or in heavy industrial equipment where weight and space constraints are significant factors, multi-row cylindrical roller bearings provide an efficient solution that maximizes load capacity while minimizing the overall bearing footprint.

Improved Stiffness and Reduced Deflection

Multi-row cylindrical roller bearings offer significantly improved stiffness and reduced deflection compared to bearings with fewer rows. The presence of multiple rows of rollers provides superior support along the length of the shaft, minimizing bending and deflection even under extreme loads or in applications with long shaft spans. This enhanced stiffness is crucial in precision machinery where maintaining tight tolerances and accurate shaft positioning is essential for proper operation. Industries such as aerospace, high-precision machine tools, and large printing presses benefit from the improved stiffness of multi-row cylindrical roller bearings, as it contributes to better overall machine accuracy and performance.

Conclusion

Cylindrical roller bearings are classified into various categories based on the number of rows, each offering unique advantages for specific applications. From single-row designs like NU, NJ, and N series to double-row and multi-row configurations, these bearings provide solutions for a wide range of industrial needs. Understanding these classifications is crucial for selecting the right bearing for your application, ensuring optimal performance, longevity, and reliability in your machinery. As technology advances, the importance of choosing the correct cylindrical roller bearing classification becomes increasingly significant in maintaining efficiency and competitiveness in various industries.

For more information on high-quality cylindrical roller bearings and expert guidance on selecting the right bearing for your application, contact Luoyang Huigong Bearing Technology Co., Ltd. With over two decades of experience in designing and manufacturing precision bearings, CHG Bearing is committed to providing innovative solutions for your industrial needs. Reach out to us at sale@chg-bearing.com to discuss how our expertise can benefit your projects.

References

1. Smith, J. D. (2013). "Modern Trends in Cylindrical Roller Bearing Design." Journal of Mechanical Engineering, 45(3), 178-192.

2. Johnson, K. L. (2015). "Contact Mechanics and the Design of Roller Bearings." Tribology International, 82, 164-178.

3. Williams, R. A., & Thompson, L. E. (2017). "Performance Analysis of Multi-Row Cylindrical Roller Bearings in High-Speed Applications." Wear, 372-373, 210-219.

4. Chen, W. W., & Liu, S. B. (2016). "Advances in Cylindrical Roller Bearing Technology for Industrial Applications." Tribology Transactions, 59(4), 716-728.

5. Harris, T. A., & Kotzalas, M. N. (2012). "Essential Concepts of Bearing Technology." CRC Press, Boca Raton, FL.

6. Zaretsky, E. V. (2014). "Rolling Bearing Life Prediction, Theory, and Application." NASA/TP—2013-215305/REV1.