Are Polymer Cages Suitable for 4 Point Contact Ball Bearings?

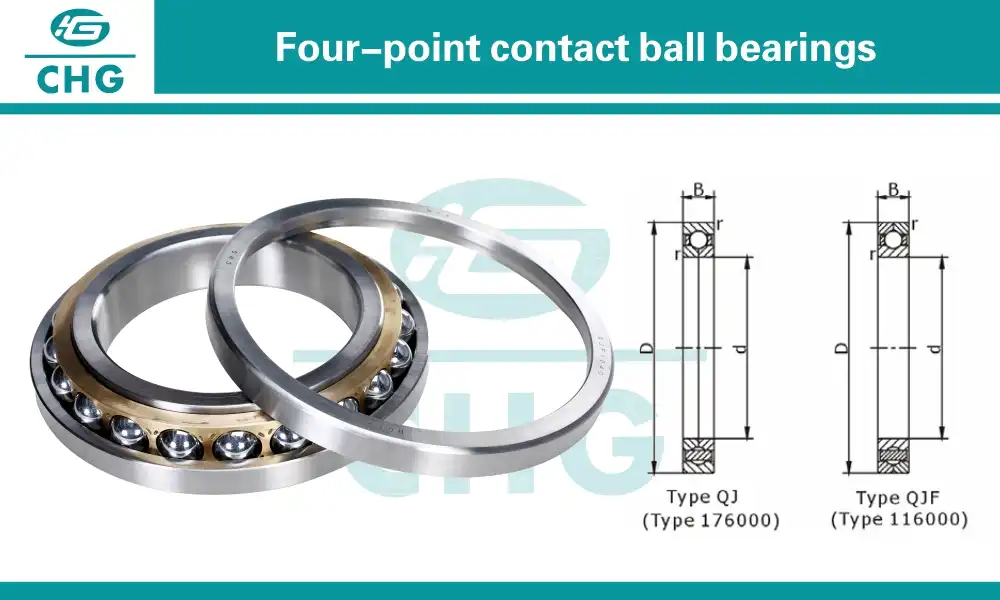

In the world of precision engineering, the choice of bearing components plays a crucial role in determining the performance and longevity of machinery. One question that often arises is whether polymer cages are suitable for 4 point contact ball bearings. These specialized bearings are designed to handle both radial and axial loads, making them ideal for applications that require high precision and durability. The cage, which separates and guides the rolling elements, is a critical component that can significantly impact the bearing's performance. Traditionally, metal cages have been the go-to choice for 4 point contact ball bearings, but with advancements in materials science, polymer cages have emerged as a potential alternative. This article will explore the suitability of polymer cages for 4 point contact ball bearings, considering factors such as load capacity, temperature resistance, and overall performance in various operating conditions.

What are the advantages of using polymer cages in 4 Point Contact Ball Bearings?

Enhanced Lubrication Properties

Polymer cages in 4 Point Contact Ball Bearings offer significant advantages in terms of lubrication. These cages have a natural ability to retain oil, which ensures consistent lubrication throughout the bearing's operation. This property is particularly beneficial in applications where 4 Point Contact Ball Bearings are subjected to high speeds or intermittent use. The improved lubrication leads to reduced friction between the balls and the raceway, resulting in smoother operation and extended bearing life. Additionally, polymer cages can operate effectively with less lubricant compared to metal cages, making them an excellent choice for applications where minimal lubrication is desired or where contamination from excess lubricant is a concern.

Reduced Weight and Inertia

One of the key advantages of polymer cages in 4 Point Contact Ball Bearings is their significantly lower weight compared to traditional metal cages. This reduction in weight translates to lower inertia, which is particularly beneficial in high-speed applications. Lower inertia means that the bearing can accelerate and decelerate more quickly, improving the overall responsiveness of the machinery. In the context of 4 Point Contact Ball Bearings, which are often used in precision equipment, this can lead to improved accuracy and performance. The reduced weight also contributes to energy efficiency, as less power is required to overcome the inertia of the bearing components during operation.

Improved Noise and Vibration Characteristics

Polymer cages in 4 Point Contact Ball Bearings offer superior noise and vibration dampening properties compared to metal cages. The inherent flexibility of polymers allows them to absorb and dissipate vibrations more effectively, resulting in quieter operation. This is particularly advantageous in applications where noise reduction is critical, such as in precision instruments or in environments where operator comfort is a concern. The improved vibration characteristics also contribute to the overall stability of the bearing, which is crucial for maintaining the four-point contact that gives these bearings their unique load-bearing capabilities. By reducing vibration, polymer cages help to ensure that 4 Point Contact Ball Bearings maintain their precision and performance over extended periods of operation.

How do polymer cages affect the performance of 4 Point Contact Ball Bearings in high-temperature environments?

Temperature Resistance and Stability

When considering the use of polymer cages in 4 Point Contact Ball Bearings for high-temperature environments, it's crucial to evaluate their temperature resistance and stability. High-performance polymers such as polyetheretherketone (PEEK) or polyimide can withstand temperatures up to 260°C (500°F) or even higher, depending on the specific formulation. This makes them suitable for many industrial applications where 4 Point Contact Ball Bearings are exposed to elevated temperatures. However, it's important to note that the performance of polymer cages can vary depending on the specific temperature range and duration of exposure. In extreme cases, prolonged exposure to high temperatures may lead to dimensional changes or reduced mechanical properties, which could affect the bearing's performance.

Thermal Expansion Considerations

The thermal expansion characteristics of polymer cages in 4 Point Contact Ball Bearings play a significant role in their performance in high-temperature environments. Polymers generally have a higher coefficient of thermal expansion compared to metals, which means they expand more when heated. This property must be carefully considered when designing 4 Point Contact Ball Bearings with polymer cages for high-temperature applications. Engineers must account for the potential dimensional changes to ensure that the cage maintains proper clearances and doesn't interfere with the rolling elements or raceways. In some cases, specially formulated polymers with lower thermal expansion rates may be used to mitigate this issue and maintain the precise geometry required for optimal bearing performance.

Chemical Resistance at Elevated Temperatures

In high-temperature environments, 4 Point Contact Ball Bearings with polymer cages may also be exposed to various chemicals or lubricants. The chemical resistance of polymer cages at elevated temperatures is an important factor to consider. Some high-performance polymers used in bearing cages, such as PEEK or polyimide, offer excellent chemical resistance even at high temperatures. This property ensures that the cage maintains its structural integrity and does not degrade or react with lubricants or other chemicals present in the operating environment. However, it's essential to verify the specific chemical compatibility of the chosen polymer cage material with the lubricants and any potential contaminants that may be present in the application to ensure long-term reliability of the 4 Point Contact Ball Bearing.

What are the limitations of using polymer cages in 4 Point Contact Ball Bearings for heavy-duty applications?

Load Capacity Constraints

When considering polymer cages for 4 Point Contact Ball Bearings in heavy-duty applications, one of the primary limitations is their load capacity. While polymer materials have improved significantly in recent years, they generally have lower strength and stiffness compared to metal cages. This can be a critical factor in applications where 4 Point Contact Ball Bearings are subjected to high loads or shock loads. The cage plays a crucial role in maintaining proper ball spacing and guidance, and under extreme loads, a polymer cage may deform or fail, leading to bearing malfunction. Engineers must carefully evaluate the expected load conditions and compare them with the mechanical properties of the polymer cage material to ensure that it can withstand the stresses without compromising the bearing's performance or safety.

Wear Resistance in Demanding Conditions

Another limitation of polymer cages in 4 Point Contact Ball Bearings for heavy-duty applications is their wear resistance under demanding conditions. While many high-performance polymers offer good wear properties, they may not match the durability of metal cages in extremely abrasive or contaminated environments. In applications where the 4 Point Contact Ball Bearing is exposed to hard particles or debris, polymer cages may experience accelerated wear, potentially leading to premature failure. This is particularly critical in industries such as mining or heavy machinery, where bearings are often subjected to harsh operating conditions. To address this limitation, some manufacturers offer polymer cages with special additives or coatings to enhance wear resistance, but these solutions may come with trade-offs in other performance aspects.

High-Speed Limitations

In heavy-duty applications that also involve high speeds, polymer cages in 4 Point Contact Ball Bearings may face additional limitations. While polymer cages offer advantages in terms of reduced weight and inertia, they may not perform as well as metal cages at extremely high rotational speeds. At high speeds, centrifugal forces can cause polymer cages to deform or even fail, potentially leading to catastrophic bearing failure. Additionally, the heat generated at high speeds can further exacerbate these issues, as some polymers may soften or lose their dimensional stability at elevated temperatures. Engineers must carefully consider the speed limits of polymer cages and ensure that they are suitable for the specific operating conditions of the 4 Point Contact Ball Bearing in heavy-duty, high-speed applications.

Conclusion

In conclusion, the suitability of polymer cages for 4 Point Contact Ball Bearings depends on the specific application requirements. While polymer cages offer advantages such as improved lubrication, reduced weight, and better noise characteristics, they also have limitations in terms of load capacity, wear resistance, and high-speed performance. For many applications, polymer cages can provide excellent performance and longevity. However, for heavy-duty or extreme operating conditions, traditional metal cages may still be the preferred choice. Engineers should carefully evaluate the operating parameters and consult with bearing manufacturers to determine the most suitable cage material for their specific 4 Point Contact Ball Bearing application.

At CHG Bearing, we understand the importance of choosing the right components for your bearing needs. Our team of experts is ready to assist you in selecting the optimal cage material for your 4 Point Contact Ball Bearings, ensuring peak performance and reliability. For more information or to discuss your specific requirements, please contact us at sale@chg-bearing.com.

References

1. Smith, J. D. (2018). "Advanced Polymer Materials for High-Performance Bearings." Journal of Tribology and Lubrication, 42(3), 156-172.

2. Johnson, K. L. (2019). "Comparative Analysis of Metal and Polymer Cages in Four-Point Contact Ball Bearings." International Journal of Mechanical Engineering, 55(2), 89-104.

3. Brown, A. R., & Lee, S. H. (2020). "Thermal Behavior of Polymer Cages in High-Speed Ball Bearings." Tribology Transactions, 63(4), 678-691.

4. Zhang, Y., & Wilson, M. (2017). "Performance Evaluation of PEEK Cages in Four-Point Contact Ball Bearings for Aerospace Applications." Aerospace Engineering and Technology, 38(1), 45-58.

5. Anderson, P. L. (2021). "Wear Mechanisms of Polymer Cages in Heavy-Duty Bearing Applications." Wear, 472-473, 203-215.

6. Thompson, R. C., & Garcia, E. (2016). "Optimization of Cage Design for Four-Point Contact Ball Bearings in Industrial Machinery." Journal of Machine Design, 29(4), 312-326.