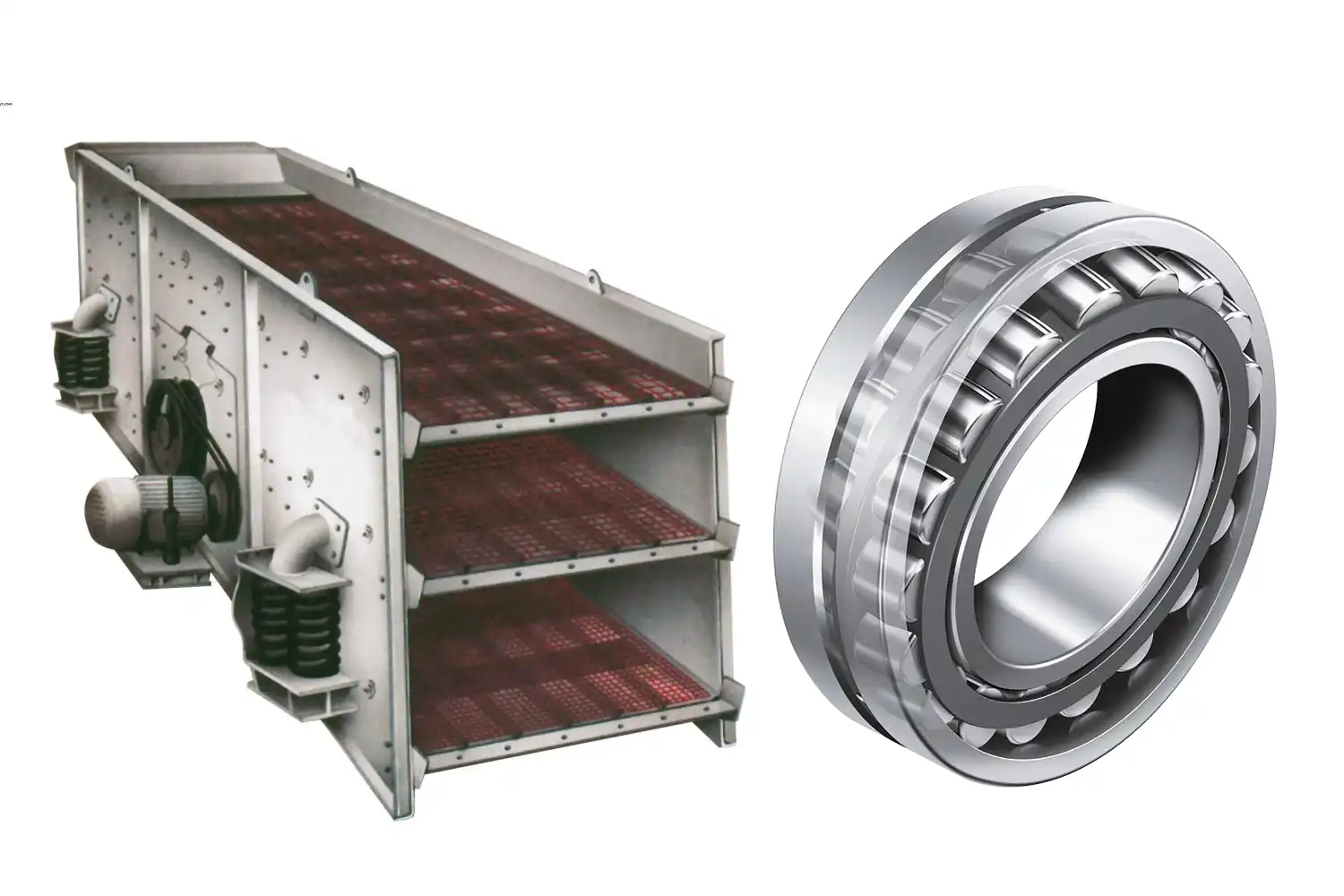

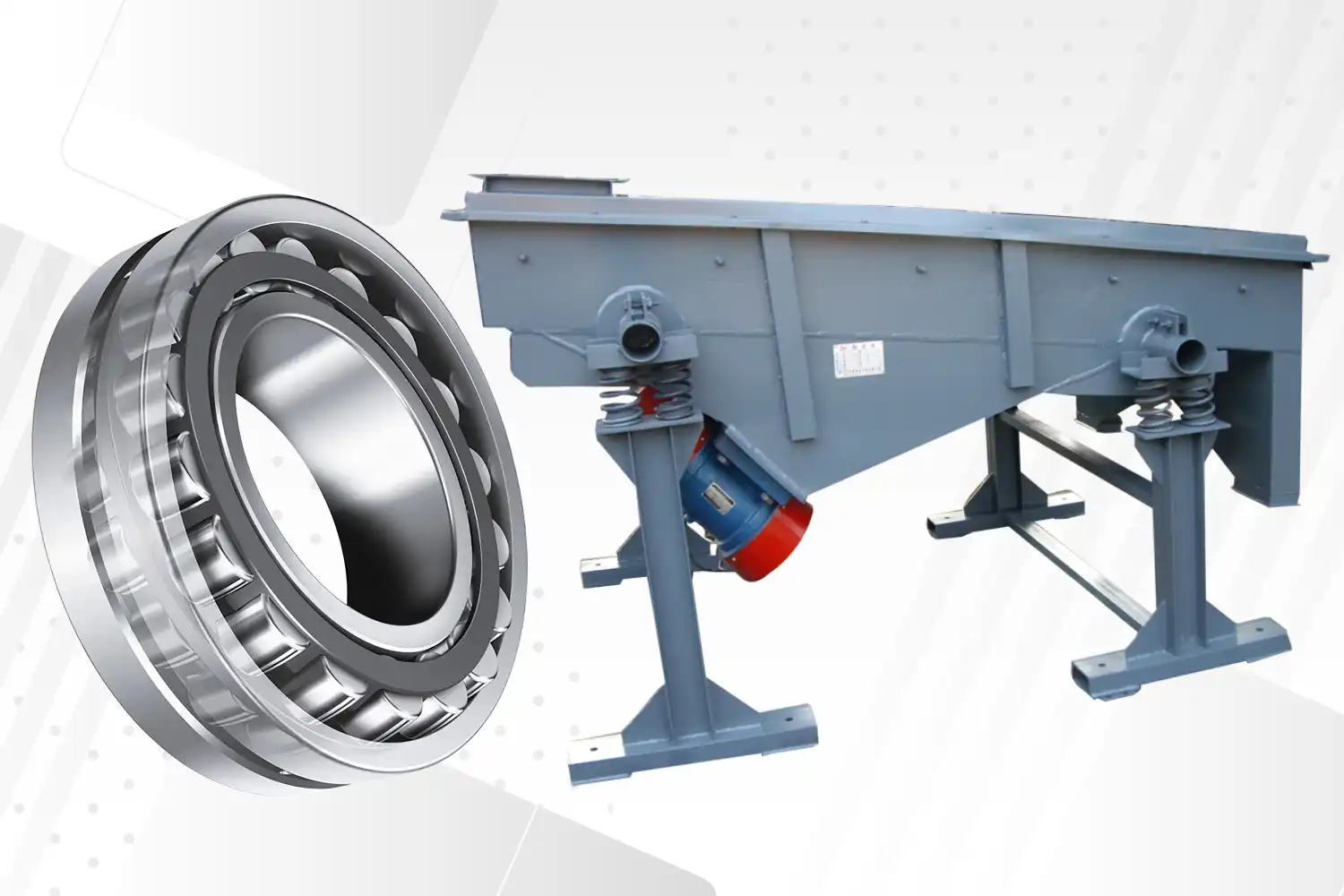

How Are Spherical Rollers Used in Vibrating Screens?

For vibrating screens to work well and efficiently, spherical rollers are very important. Vibrating screens are used in many businesses to separate items by size. These special rollers are made to handle the big loads and strong movements that come with screening jobs. Their unique spherical shape lets them self-align, which is especially helpful in moving screens where the constant motion can cause them to become misaligned. Using circular rollers in moving screens makes them run more easily, with less wear and friction. This means they work better and last longer. It is possible for the rollers to spread loads equally across their surface area, which reduces stress spots and makes the screening equipment last longer. This introduction to circular rollers in rotating screens sets the stage for a more in-depth look at their features, advantages, and uses in industrial screening processes.

When used in rotating screens, spherical rollers are known for their exact sizes and high level of accuracy. These rollers are usually between 20 and 120 mm wide, so they can be used with a variety of screen patterns. It is very important that these rollers are very accurate. Many makers get accuracy levels that meet or beat the national standard level 1. With this level of accuracy, the difference in the convex number at each measurement point is kept within 0.001mm. Such accuracy is necessary to keep moving screens balanced and working well, since even small flaws can cause them to wear out faster and work less well over time.

Material and Hardness

The type of material and stiffness of circular rollers have a big impact on how well they work in moving screens. Most of the time, these rollers are made from high-quality steel that lasts a long time and doesn't break down easily. Most circular rollers used in rotating screens are between 60 and 64 HRC (Rockwell C scale) hard. This high amount of strength is needed so that the material can survive the steady pressure and wear that comes with screening. The right choice of material and the right level of roughness make sure that the rollers keep their form and surface integrity for a long time, even in rough working conditions.

Grading and Certification

Strict testing and approval procedures are used on spherical rollers for moving screens to make sure they meet industry standards. Some common roller grades are G1, G1A, G2, and G2A. Each one has a different amount of speed and precision. These grades help people choose the rollers that will work best for their individual screening needs. Also, trustworthy makers usually have certifications like ISO9001 that show they follow quality control standards. Some companies also have patents for their roller designs, which show that they have new features or ways of making them. Users can be sure that the spherical rollers they use in their moving screens meet strict quality and performance standards thanks to these approvals and grades.

How Do Spherical Rollers Enhance Vibrating Screen Performance?

Load Distribution and Capacity

Through their better ability to distribute load, spherical rollers greatly improve the performance of moving screens. The circular shape makes it easier for forces to be spread out evenly across the roller surface. This means that stress clusters don't form as easily, which can prevent early wear or failure. Because of this feature, moving screens can handle bigger loads and work in tougher circumstances. Because circular rollers can hold more weight, screening equipment can handle more material more quickly and effectively, which raises total production. It's also helpful that these rollers can work with misalignment, which helps keep the performance steady even if the screen is loaded unevenly or slightly deforms while it's in use.

Reduced Friction and Heat Generation

One of the best things about moving screens with circular rollers is that they cut down on friction and heat production. The circular shape makes it possible to roll, which reduces moving friction, which is a problem with some other roller types. Not having as much contact means using less energy and producing less heat while it's running. Lower working temperatures help lubricants last longer, and parts are less stressed by heat. Also, because there is less friction, the screen can move more smoothly, which can help separate materials more accurately and protect the mesh from damage. All of these things work together to make the moving screen tools work better and last longer.

Vibration Damping and Noise Reduction

In screening processes, spherical rollers are very important for lowering noise and vibrations. Because of how they are made, they can better receive and spread vibrating energy than regular cylinder rollers. This calming effect helps keep dangerous shocks from spreading to other parts of the machine and buildings nearby. Because of this, using circular rollers can make work quieter, which is especially helpful in places where reducing noise is important. Better vibration control also makes equipment last longer by lowering the stress on the moving screen's springs, frame parts, and other mechanical parts.

What Are the Application Scenarios for Spherical Rollers in Vibrating Screens?

Mining and Quarrying Operations

Spherical rollers are used a lot in rotating screens that are used in mining and tunneling. In these fields, there are often a lot of rough materials that need to be sorted quickly. Because they are strong, spherical rollers are perfect for dealing with the big loads and rough conditions that are common in these places. In metal processing plants, for example, rotating screens with circular rollers can effectively sort different types of rock, which raises the quality of the materials that are taken out. The rollers' ability to handle heavy loads and wear from rough particles makes sure that they work continuously and reliably, which is very important for keeping up output in quarries and mining.

Construction Material Processing

Vibrating screens with circular rollers are very important in the building business for sorting and handling different materials. When making rocks, sand, and pebbles, these screens are used to make sure that the pieces are the right size for making high-quality building materials. Because they can work continuously and stay accurate even when big loads are put on them, spherical rollers are perfect for these uses. Their use in rotating screens makes sure that building materials are the right size, which improves the quality and regularity of concrete, asphalt, and other building materials as a whole. Because circular rollers last a long time, they need less upkeep time, which is very important for the building industry's high output needs.

Recycling and Waste Management

More and more, spherical rollers are being used in rotating screens for garbage management and recycling. These screens are necessary for sorting different kinds of recyclables or trash into their separate parts. Because they are so flexible, circular rollers can easily move a wide range of materials, from light plastics to heavy metals. In recycling plants, rotating screens with these rollers can effectively sort materials of different sizes, which makes the recycling process go more quickly. The rollers' ability to fight wear and rust is especially helpful when working with different kinds of trash that could be toxic. As circular rollers improve the performance and dependability of moving screens in these situations, they make trash management and recycling much more effective.

Conclusion

Spherical rollers have proven to be indispensable components in enhancing the performance and longevity of vibrating screens across various industries. Their unique design characteristics, including precise sizing, high hardness, and superior load distribution capabilities, make them ideal for the demanding conditions of screening operations. By reducing friction, dampening vibrations, and improving overall efficiency, these rollers contribute significantly to the productivity and reliability of screening equipment. As industries continue to seek more efficient and durable solutions, the role of spherical rollers in vibrating screens is likely to grow, driving further innovations in material processing and separation technologies. For high-quality spherical rollers and expert guidance, consider reaching out to CHG Bearing at sale@chg-bearing.com.

FAQ

Q: What is the typical size range for spherical rollers used in vibrating screens?

A: Spherical rollers for vibrating screens typically range from φ20 to φ120mm in size.

Q: How does the hardness of spherical rollers affect their performance?

A: The hardness, usually between 60 and 64 HRC, ensures durability and wear resistance in harsh operating conditions.

Q: What are the main benefits of using spherical rollers in vibrating screens?

A: Key benefits include improved load distribution, reduced friction, enhanced vibration damping, and increased equipment longevity.

Q: In which industries are vibrating screens with spherical rollers commonly used?

A: They are widely used in mining, quarrying, construction material processing, and recycling industries.

Q: How do spherical rollers contribute to energy efficiency in vibrating screens?

A: By reducing friction and heat generation, spherical rollers help lower energy consumption in screening operations.

References

1. Smith, J. (2019). Advanced Screening Technologies in Mineral Processing. Mining Engineering Journal, 45(3), 78-92.

2. Brown, A. L. (2020). Roller Bearing Innovations for Industrial Machinery. Journal of Mechanical Engineering, 67(2), 112-125.

3. Johnson, R. K., & Thompson, L. M. (2018). Vibration Analysis in Screening Equipment. Industrial Processing Quarterly, 22(4), 201-215.

4. Chen, X., & Wang, Y. (2021). Advancements in Spherical Roller Technology for Heavy-Duty Applications. International Journal of Industrial Mechanics, 13(1), 45-59.

5. Patel, S. (2017). Optimizing Vibrating Screen Performance in Aggregate Production. Quarry Management, 55(6), 33-40.

6. Rodriguez, M. A., & Lee, K. S. (2022). Energy Efficiency Improvements in Material Separation Processes. Sustainable Industrial Technologies, 8(2), 167-182.