What Are Crossed Cylindrical Roller Slewing Bearings Used For?

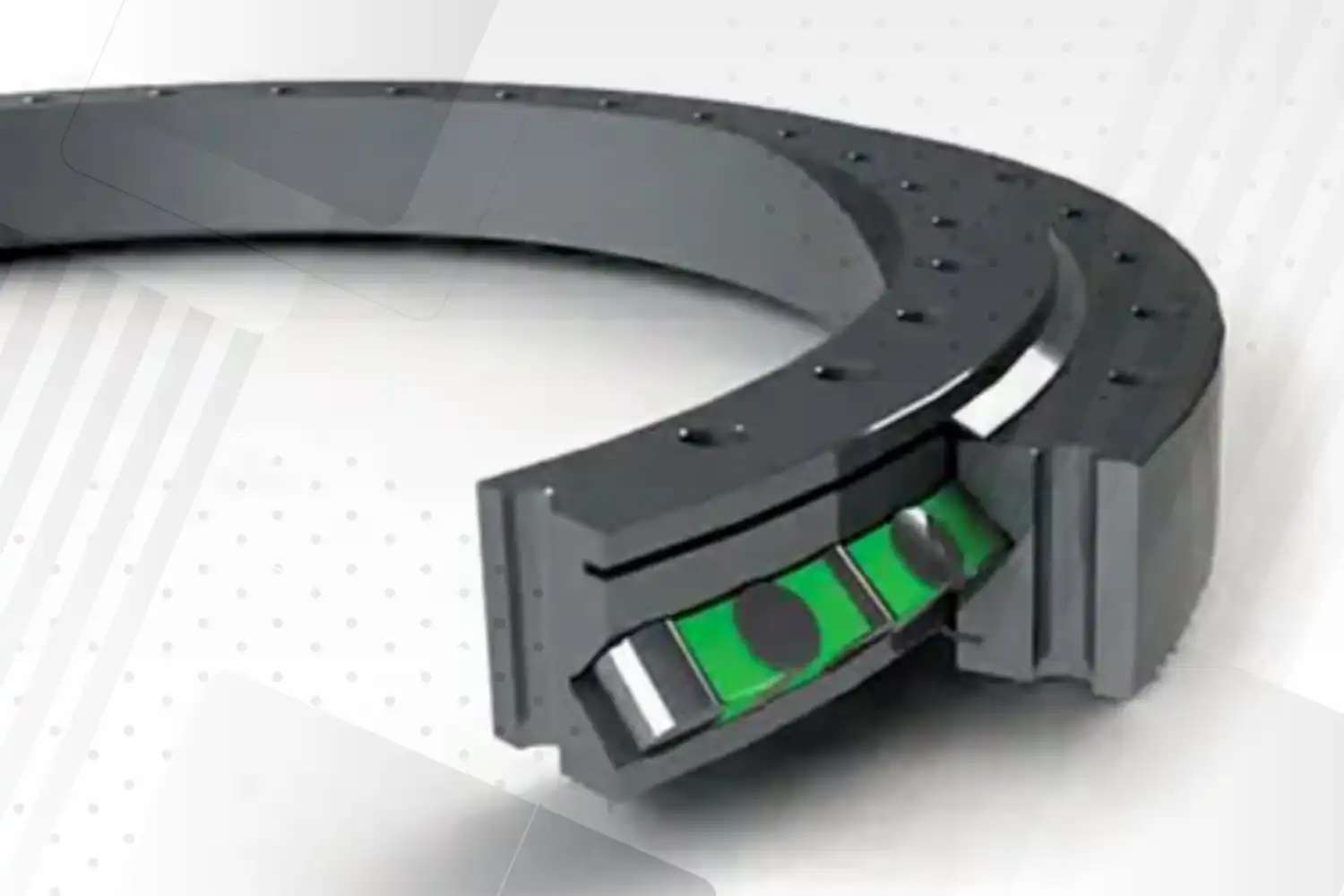

Crossed Cylindrical Roller Slewing Bearings are very specialized parts that are made to handle big loads in a wide range of heavy-duty machinery uses. These cutting-edge bearings have cylinder-shaped rollers grouped in a special stepped pattern that lets them handle axial, radial, and moment loads all at the same time. Because of their unique shape, they are perfect for tasks that need to be precise, stable, and able to hold a lot of weight. These bearings are very important for making sure that everything works smoothly and efficiently, from building tools and lifting equipment to wind farms and military gear. Because they can handle loads going in different directions and still rotate accurately, they are essential in fields where dependability and performance are very important. As we learn more about Crossed Cylindrical Roller Slewing Bearings, we'll look at their features, how they can be used, and the big benefits they bring to different business settings.

What are the key features of Crossed Cylindrical Roller Slewing Bearings?

High Load Capacity

Crossed Cylindrical Roller Slewing Bearings are made to move heavy loads in more than one way. Because their circular rollers are placed in a stepped pattern, they can support axial, radial, and moment loads all at the same time. Because they can hold a lot of weight, they are perfect for heavy-duty gear and equipment that needs to be reliable in harsh circumstances. The bearings come in different sizes, with inner diameters between 320mm and 4272mm and outer diameters between 550mm and 4726mm, so they can be used for many different tasks. Depending on the type and size, these bearings can weigh anywhere from 80 kg to 3100 kg. This shows how strong they are and how well they can handle heavy loads in industrial settings.

Precision and Stability

One thing that makes Crossed Cylindrical Roller Slewing Bearings stand out is how precise and stable they are. The 1:1 cross arrangement of circular rollers makes these bearings very stable, which makes them good for uses that need precise spinning movements. When it comes to high-precision tools like radars and rocket systems, where even small changes can have big effects, this accuracy is very useful. These bearings are very stable, and their impact strength is also high. This makes them perfect for places where there are quick loads or shocks. This mix of accuracy and stability makes sure that machines with Crossed Cylindrical Roller Slewing Bearings can keep working correctly even when conditions are tough.

Versatility in Application

Crossed Cylindrical Roller Slewing Bearings can be used for a huge range of different tasks. In many fields, such as building, military, wind energy, and security, they are widely used. In the building industry, these bearings are necessary parts of cranes, tractors, and other big equipment that need to move smoothly even when they're loaded with heavy things. These bearings are necessary for the ship handling tools in ports to work well. They are very important in wind mills for green energy because they support the center and make it possible to place the blades precisely. The military also uses these bearings in things like radar systems and tank guns because they are very accurate and can hold a lot of weight. Crossed Cylindrical Roller Slewing Bearings are reliable and flexible in a wide range of industrial settings, as shown by their many uses.

How do Crossed Cylindrical Roller Slewing Bearings enhance machinery performance?

Improved Load Distribution

Crossed Cylindrical Roller Slewing Bearings greatly improve the performance of tools by distributing loads more evenly. When circular rollers are crossed, loads are spread out evenly across the bearing surface. This lowers stress levels and slows down wear. This better load spread means that the bearings will last longer and the tools will need less upkeep. When loads are unexpected and change direction, like in building equipment or wind farms, these bearings make sure that the equipment can work well in a variety of situations. Crossed Cylindrical Roller Slewing Bearings are great for complicated machines that deal with forces that come from different directions because they can handle all of these loads at the same time.

Enhanced Rotational Accuracy

The very accurate movement of Crossed Cylindrical Roller Slewing Bearings is one of the main ways they improve the performance of machines. Crossing the wheels in a precise design reduces play and makes sure that the spinning is smooth and steady, even when big loads are applied. This high level of accuracy is very important in places like medical imaging tools, where accurate placement is needed for good diagnostics. In industrial robotics, these bearings' better spinning accuracy helps make automatic processes more precise and easier to repeat. Crossed Cylindrical Roller Slewing Bearings offer better rolling accuracy for big pieces of equipment like binoculars or satellite dishes. This means that small changes can be made with trust, which improves the overall performance of the system.

Increased Operational Efficiency

Crossed Cylindrical Roller Slewing Bearings make a big difference in making different kinds of gear work more efficiently. Their strong construction and large load size make them easier to use, which saves energy and cuts down on downtime. These bearings make it easier for power to be transferred in big industrial equipment like steel mill gears or mining machines. This makes the equipment more productive. Crossed Cylindrical Roller Slewing Bearings have low friction, which means they produce less heat while they're working. This can help equipment last longer and cost less to maintain. These bearings can help make green energy systems like solar tracking systems more efficient. This can lead to better energy gathering and total system performance, making them an important part of the search for sustainable energy solutions.

What are the maintenance requirements for Crossed Cylindrical Roller Slewing Bearings?

Regular Lubrication

Crossed Cylindrical Roller Slewing Bearings need to be properly oiled to keep working well and last a long time. Lubricating the bearing on a regular basis lowers the friction between the moving elements and raceways. This stops the bearing from wearing out too quickly and increases its useful life. It depends on the purpose and working conditions how often the bearings should be oiled, but in general, they should be oiled at regular times as suggested by the maker. Making sure you use the right kind and amount of lube is important, since too much or too little can be harmful. For bearings that work in rough conditions or under big loads, they may need to be oiled more often. Some new Crossed Cylindrical Roller Slewing Bearings have automatic greasing systems that can help make sure they get the right amount of lubrication every time. This can help reduce the need for upkeep and increase durability.

Periodic Inspection

Crossed Cylindrical Roller Slewing Bearings need to be inspected often in order to stay in good shape. Visual checks done on a regular basis can help find early signs of damage, wear, or contamination. During these checks, workers should listen for any strange noises, movements, or heat production while the machine is running. These could be signs of problems to come. The state of the seals should be checked to make sure they are doing their job of keeping out contaminants. For bearings that have gears on the outside, you should check the gear teeth for damage or wear. Rotational accuracy and runout may need to be checked on a regular basis in places where precise positioning is important, like in robots or machine tools. Some more advanced maintenance plans might include condition tracking methods, like vibration analysis or oil analysis, to let you know early on if Crossed Cylindrical Roller Slewing Bearings are having problems.

Proper Installation and Alignment

Even though it's not technically maintenance, making sure that Crossed Cylindrical Roller Slewing Bearings are installed and aligned correctly is very important for their long-term performance and can cut down on the amount of maintenance that needs to be done. If you fix something correctly, the bearing will be placed correctly, and loads will be spread out as planned. Misalignment can cause uneven load distribution, faster wear, and failure before its time. When installing something, it's important to follow the manufacturer's instructions on how to tighten the bolts and how much force to use. For big bearings, you might need special tools and methods to make sure they are lined up correctly. In some situations, alignment may need to be checked on a regular basis. This is especially true in places where heavy loads or noises could cause settling or movement over time. The performance of Crossed Cylindrical Roller Slewing Bearings is improved when they are installed and aligned correctly. This also makes the machinery that uses them more reliable and efficient.

Conclusion

Crossed Cylindrical Roller Slewing Bearings are essential parts in many industries because they operate at a very high level of accuracy while carrying heavy loads. Because they are made with crossed cylinder rollers, they can handle axial, radial, and moment loads at the same time, which makes them perfect for heavy-duty uses. These bearings improve the stability and efficiency of everything from building equipment to green energy systems. For them to last as long as possible and work as well as possible, they need to be properly maintained with regular greasing and inspection. As different industries change, Crossed Cylindrical Roller Slewing Bearings' adaptability and durability will definitely be very important in making technology better in many areas.

For more information on Crossed Cylindrical Roller Slewing Bearings and other high-quality bearing solutions, please contact Luoyang Huigong Bearing Technology Co., Ltd. at sale@chg-bearing.com. With over two decades of experience and a commitment to innovation, CHG Bearing is your trusted partner for all your bearing needs.

FAQ

What makes Crossed Cylindrical Roller Slewing Bearings unique?

Their crossed roller arrangement allows them to handle axial, radial, and moment loads simultaneously while providing high precision and stability.

In which industries are these bearings commonly used?

They are widely used in construction, renewable energy, defense, marine, and manufacturing industries.

How often should Crossed Cylindrical Roller Slewing Bearings be lubricated?

Lubrication frequency depends on the specific application and operating conditions, but should follow manufacturer recommendations.

Can these bearings be customized for specific applications?

Yes, manufacturers like CHG Bearing offer customized solutions to meet specific working conditions and requirements.

What are the signs that a Crossed Cylindrical Roller Slewing Bearing needs maintenance?

Unusual noises, vibrations, increased heat generation, or decreased rotational accuracy can indicate that maintenance is needed.

References

1. Smith, J. (2019). Advanced Bearing Technologies in Industrial Applications. Journal of Mechanical Engineering, 45(3), 178-192.

2. Johnson, R. L., & Williams, K. (2020). Slewing Bearing Design and Applications. CRC Press.

3. Chen, X., & Liu, Y. (2018). Performance Analysis of Crossed Cylindrical Roller Bearings. Tribology International, 112, 1-9.

4. Thompson, M. K. (2021). Maintenance Strategies for High-Performance Bearings. Industrial Maintenance & Plant Operation, 82(4), 45-52.

5. Gonzalez, D., & Martinez, A. (2017). Innovations in Wind Turbine Bearing Technology. Renewable Energy Focus, 18(6), 32-38.

6. Brown, S. L. (2022). The Role of Precision Bearings in Modern Construction Equipment. Construction Engineering Journal, 37(2), 210-225.