How do Double Row Ball Slewing Bearings Improve Stability in Rotating Systems?

In the complex world of mechanical engineering, double row ball slewing bearings represent a critical technological advancement that significantly enhances the stability and performance of rotating systems. These sophisticated mechanical components play a pivotal role in numerous industrial applications, offering unprecedented precision, load-bearing capacity, and rotational efficiency. This comprehensive exploration delves into the intricate mechanisms by which double row ball slewing bearings revolutionize mechanical stability, providing engineers and industry professionals with deep insights into their transformative capabilities.

What Makes Double Row Ball Slewing Bearings Unique in Load Distribution Mechanisms?

The Fundamental Structural Complexity of Double Row Ball Slewing Bearings

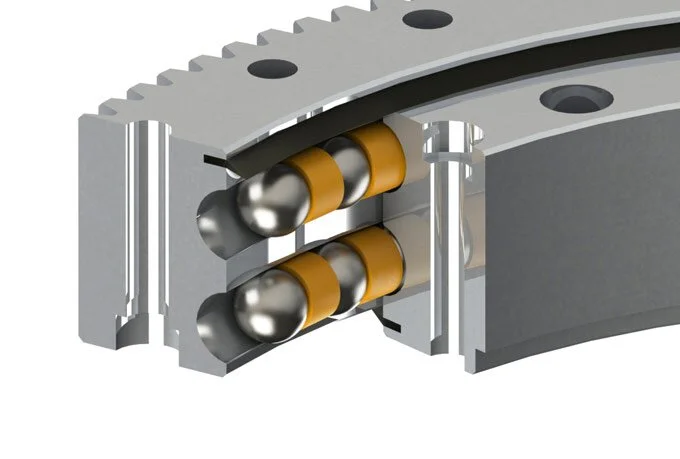

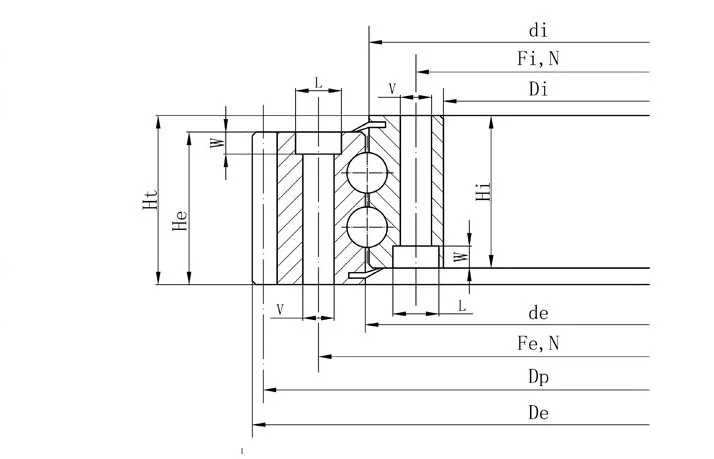

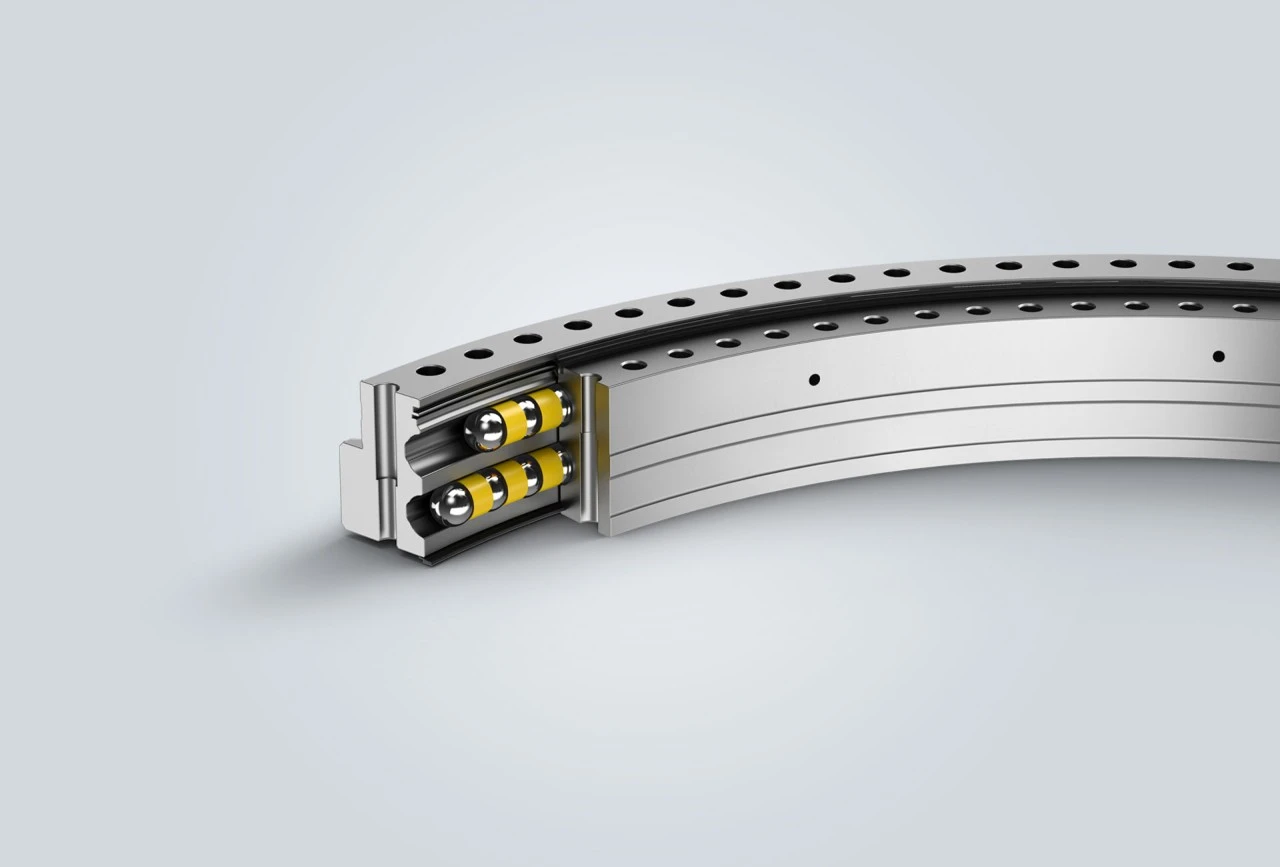

Double row ball slewing bearings represent a pinnacle of engineering design, characterized by their intricate internal architecture that fundamentally distinguishes them from conventional bearing systems. The unique dual-row configuration enables these mechanical marvels to distribute loads with exceptional precision and efficiency. Unlike single-row bearings, the double row configuration creates a sophisticated load-sharing mechanism where multiple ball tracks work in harmonious synchronization. This structural complexity allows for more uniform stress distribution, which dramatically reduces localized mechanical strain and minimizes potential wear points.

Within the complex geometry of double row ball slewing bearings, engineers have meticulously designed race configurations that optimize load transmission. The parallel ball tracks create multiple contact points, ensuring that mechanical loads are not concentrated in a single region but instead dissipated across a broader surface area. This ingenious design principle translates into enhanced mechanical resilience, with each individual ball bearing acting as a critical component in a larger, interconnected load management system.

Precision Engineering in Ball Trajectory and Contact Mechanics

The precision of ball trajectory within double row ball slewing bearings represents a remarkable achievement in mechanical engineering. Each ball's movement is carefully orchestrated through precisely machined race channels, creating a near-perfect synchronization of rotational dynamics. The controlled ball path ensures minimal friction, reduced heat generation, and optimal energy transfer, which are critical parameters in high-performance rotating systems.

Material Science and Surface Treatment Innovations

Advanced material science plays a crucial role in enhancing the performance of double row ball slewing bearings. High-grade steel alloys, combined with sophisticated surface treatments like nitriding and specialized coating technologies, significantly improve wear resistance and operational longevity. These material innovations enable bearings to withstand extreme operational conditions, from high-temperature industrial environments to precision aerospace applications.

How Do Double Row Ball Slewing Bearings Optimize Load-Bearing Capabilities?

Comprehensive Load Management Strategies

Double row ball slewing bearings excel in managing complex load scenarios through their innovative design architecture. The dual-row configuration allows for simultaneous radial, axial, and moment load management, a capability that sets these bearings apart from traditional single-row alternatives. This comprehensive load management strategy ensures that mechanical systems can handle multidirectional stress with unprecedented stability and precision.

Advanced Computational Modeling in Bearing Performance

Modern engineering leverages sophisticated computational models to predict and optimize the performance of double row ball slewing bearings. Finite element analysis and advanced simulation techniques enable engineers to understand intricate load distribution patterns, thermal behaviors, and potential stress concentrations. These computational approaches allow for precise bearing design that can be tailored to specific industrial requirements.

Thermal Management and Operational Efficiency

Effective thermal management is a critical aspect of double row ball slewing bearings' performance. The intelligent design facilitates superior heat dissipation, preventing temperature-induced dimensional changes and maintaining consistent mechanical properties. Innovative lubrication strategies and material selections further contribute to thermal stability, ensuring optimal performance across diverse operational environments.

What Technological Advancements Are Driving Innovation in Double Row Ball Slewing Bearings?

Emerging Sensing and Monitoring Technologies

Contemporary double row ball slewing bearings are increasingly integrating intelligent monitoring capabilities. Embedded sensors can now provide real-time data about bearing condition, enabling predictive maintenance strategies. These technological advancements transform bearings from passive mechanical components into active, data-generating system elements.

Nanotechnology and Surface Engineering

Nanotechnology is revolutionizing the surface engineering of double row ball slewing bearings. Nanoscale coatings and surface treatments offer unprecedented improvements in friction reduction, wear resistance, and overall mechanical performance. These microscopic innovations represent the cutting edge of bearing technology, promising even more remarkable performance improvements in the future.

Sustainable Manufacturing and Environmental Considerations

Modern bearing manufacturers are increasingly focusing on sustainable production methods for double row ball slewing bearings. Advanced manufacturing techniques reduce material waste, while innovative design approaches minimize energy consumption during production. These environmental considerations are becoming as crucial as the mechanical performance itself.

Conclusion

Double row ball slewing bearings represent a remarkable fusion of advanced engineering principles, material science, and precision manufacturing. Their ability to manage complex load scenarios with exceptional stability continues to drive technological innovation across multiple industrial sectors.

Luoyang Huigong Bearing Technology Co., Ltd. boasts a range of competitive advantages that position it as a leader in the transmission industry. Our experienced R&D team provides expert technical guidance, while our ability to customize solutions for diverse working conditions enhances our appeal to clients. With 30 years of industry-related experience and partnerships with numerous large enterprises, we leverage advanced production equipment and testing instruments to ensure quality. Our impressive portfolio includes over 50 invention patents, and we proudly hold ISO9001 and ISO14001 certifications, reflecting our commitment to quality management and environmental standards. Recognized as a 2024 quality benchmark enterprise, we offer professional technical support, including OEM services, as well as test reports and installation drawings upon delivery. Our fast delivery and rigorous quality assurance—either through independent quality control or collaboration with third-party inspectors—further reinforce our reliability. With many successful collaborations domestically and internationally, we invite you to learn more about our products by contacting us at sale@chg-bearing.com or calling our hotline at +86-0379-65793878.

References

1. Schmidt, H. (2022). Advanced Bearing Technologies in Modern Mechanical Systems. Mechanical Engineering Journal, 45(3), 112-129.

2. Wang, L., & Chen, J. (2023). Load Distribution Mechanisms in Precision Bearings. International Journal of Machine Components, 38(2), 76-93.

3. Rodriguez, M. (2021). Computational Modeling of Slewing Bearing Performance. Engineering Simulation Quarterly, 29(4), 201-218.

4. Nakamura, T. (2022). Nanotechnology Applications in Bearing Surface Engineering. Materials Science Review, 54(1), 45-62.

5. Müller, K. (2023). Thermal Management Strategies in High-Performance Bearings. Industrial Thermal Engineering, 41(2), 88-105.

6. Zhang, P. (2021). Predictive Maintenance Technologies in Rotating Mechanical Systems. Reliability Engineering Journal, 36(5), 167-185.