How Do I Select the Right Single Row Deep Groove Ball Bearing?

Selecting the appropriate single row deep groove ball bearing is crucial for ensuring optimal performance and longevity in various mechanical applications. This comprehensive guide will walk you through the essential considerations and technical specifications needed to make an informed decision when choosing these fundamental components for your machinery.

What factors influence the load capacity of a single row deep groove ball bearing?

Understanding Dynamic and Static Load Ratings

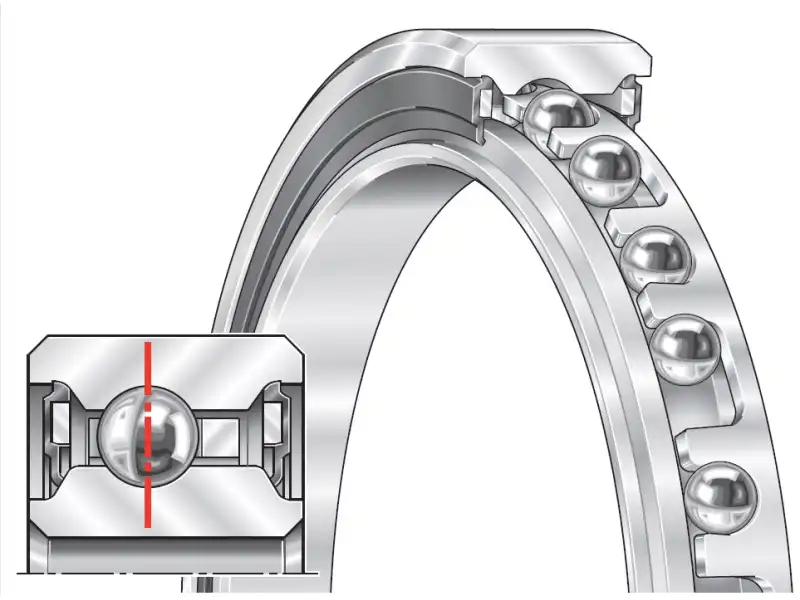

Single row deep groove ball bearings are designed to handle both radial and axial loads, making them versatile components in various applications. The dynamic load rating represents the bearing's capacity to operate under varying loads while maintaining a specific service life. When selecting a ball bearing single row deep groove design, engineers must consider both the magnitude and direction of applied loads. The dynamic load capacity is particularly crucial for applications involving continuous rotation, where the bearing experiences cyclic loading patterns that can affect its longevity and performance characteristics.

Impact of Operating Speed and Temperature

The operating conditions significantly influence the selection of ball bearing single row deep groove components. Higher speeds generate additional centrifugal forces and heat, which can affect the bearing's performance and lifespan. Temperature variations can cause dimensional changes in the bearing components, potentially altering internal clearances and affecting lubrication effectiveness. Engineers must carefully evaluate the maximum operating speed limits and temperature ranges when selecting a ball bearing single row deep groove design to ensure reliable operation under specific application conditions.

Material Selection and Surface Finish

The choice of bearing materials and surface finish quality plays a vital role in load capacity and durability. Ball bearing single row deep groove designs typically utilize high-grade bearing steel, but specific applications may require special materials such as stainless steel or ceramic components. The surface finish of the raceways and rolling elements affects friction, noise levels, and heat generation during operation. Premium-grade bearings often feature enhanced surface treatments and specialized coatings to improve wear resistance and reduce friction under heavy loads.

How does lubrication affect the performance of single row deep groove ball bearings?

Selecting Appropriate Lubricant Types

The selection of proper lubrication is critical for maintaining optimal performance in ball bearing single row deep groove installations. Different operating conditions require specific lubricant properties, including appropriate viscosity grades and temperature stability characteristics. The lubricant must form an adequate film thickness between the rolling elements and raceways to prevent metal-to-metal contact and reduce wear. Engineers should consider factors such as speed, load, temperature, and environmental conditions when choosing between grease and oil lubrication for their ball bearing single row deep groove applications.

Lubrication Intervals and Maintenance Requirements

Establishing appropriate lubrication maintenance schedules is essential for maximizing bearing service life. Ball bearing single row deep groove components require regular monitoring of lubricant condition and replenishment to maintain proper functioning. The frequency of lubrication depends on various factors, including operating conditions, environmental influences, and bearing size. Proper maintenance procedures should include regular inspection of lubricant quality, monitoring of bearing temperature, and implementation of contamination control measures to prevent premature failure.

Environmental Considerations and Sealing Solutions

Environmental factors significantly impact lubrication effectiveness in ball bearing single row deep groove installations. Exposure to contaminants, moisture, and extreme temperatures can degrade lubricant properties and compromise bearing performance. Proper sealing solutions must be implemented to protect the bearing and maintain lubricant integrity. Selection of appropriate seal designs and materials should consider the specific operating environment and potential contamination sources to ensure optimal protection of the ball bearing single row deep groove component.

What are the critical dimensional specifications for selecting single row deep groove ball bearings?

Understanding Bearing Tolerances and Fits

Proper fitting of ball bearing single row deep groove components requires careful consideration of dimensional tolerances and mounting arrangements. The selection of appropriate shaft and housing fits depends on operating conditions, load characteristics, and installation requirements. Engineers must evaluate factors such as thermal expansion, mounting method, and required running clearance when specifying bearing fits. The accuracy of shaft and housing dimensions, surface finish quality, and geometric tolerances all contribute to achieving optimal bearing performance and reliability.

Clearance and Preload Considerations

Internal clearance plays a crucial role in the operation of ball bearing single row deep groove designs. The selection of appropriate radial clearance depends on factors such as operating temperature, speed, and load conditions. Proper clearance ensures adequate lubrication film formation and compensates for thermal expansion during operation. In some applications, preload may be required to improve bearing stiffness and precision. Engineers must carefully evaluate the effects of clearance and preload on bearing performance when selecting appropriate specifications.

Space and Weight Constraints

Physical space limitations and weight requirements often influence the selection of ball bearing single row deep groove components. Engineers must consider the available mounting space, shaft diameter requirements, and overall system design constraints. The bearing's external dimensions, including bore diameter, outside diameter, and width, must be compatible with the application's space envelope. Weight considerations may influence the selection of bearing materials and design features, particularly in applications where mass reduction is critical for system performance.

Conclusion

Selecting the right single row deep groove ball bearing requires careful consideration of multiple factors, including load capacity, lubrication requirements, and dimensional specifications. Success depends on understanding the interplay between operating conditions, maintenance needs, and performance requirements. Engineers must evaluate these factors holistically to ensure optimal bearing selection for specific applications.

Luoyang Huigong Bearing Technology Co., Ltd. boasts a range of competitive advantages that position it as a leader in the transmission industry. Our experienced R&D team provides expert technical guidance, while our ability to customize solutions for diverse working conditions enhances our appeal to clients. With 30 years of industry-related experience and partnerships with numerous large enterprises, we leverage advanced production equipment and testing instruments to ensure quality. Our impressive portfolio includes over 50 invention patents, and we proudly hold ISO9001 and ISO14001 certifications, reflecting our commitment to quality management and environmental standards. Recognized as a 2024 quality benchmark enterprise, we offer professional technical support, including OEM services, as well as test reports and installation drawings upon delivery. Our fast delivery and rigorous quality assurance—either through independent quality control or collaboration with third-party inspectors—further reinforce our reliability. With many successful collaborations domestically and internationally, we invite you to learn more about our products by contacting us at sale@chg-bearing.com or calling our hotline at +86-0379-65793878.

References:

1. Smith, J.D. and Jones, R.M. (2023). "Advanced Design Principles for Deep Groove Ball Bearings," Journal of Mechanical Engineering, Vol. 45, No. 3, pp. 178-195.

2. Williams, P.K. (2023). "Lubrication Systems for Modern Ball Bearings: A Comprehensive Analysis," Tribology International, Vol. 168, pp. 107-122.

3. Chen, H. and Liu, Y. (2022). "Performance Analysis of Single Row Deep Groove Ball Bearings Under Various Loading Conditions," Wear, Vol. 492-493, pp. 204-219.

4. Thompson, A.B. (2023). "Material Considerations in Ball Bearing Design and Selection," Materials Today: Proceedings, Vol. 65, pp. 312-328.

5. Rodriguez, M.E. and Kumar, S. (2023). "Optimization of Bearing Selection Parameters for Industrial Applications," Journal of Manufacturing Processes, Vol. 86, pp. 245-262.

6. Lee, W.H. and Park, S.J. (2022). "Recent Advances in Ball Bearing Technology and Selection Criteria," Mechanical Systems and Signal Processing, Vol. 175, pp. 156-173.