Can Double Row Angular Contact Ball Bearings Handle Both Axial and Radial Loads?

Double row angular contact ball bearings represent a crucial advancement in bearing technology, specifically designed to handle complex load combinations. These specialized bearings have gained significant attention in industrial applications due to their unique ability to manage both axial and radial loads simultaneously. Their distinctive design, featuring two rows of balls arranged at specific contact angles, enables them to operate efficiently under various loading conditions while maintaining optimal performance and longevity.

What Makes Double Row Angular Contact Ball Bearings Unique in Load-Bearing Applications?

Design Features and Structural Advantages

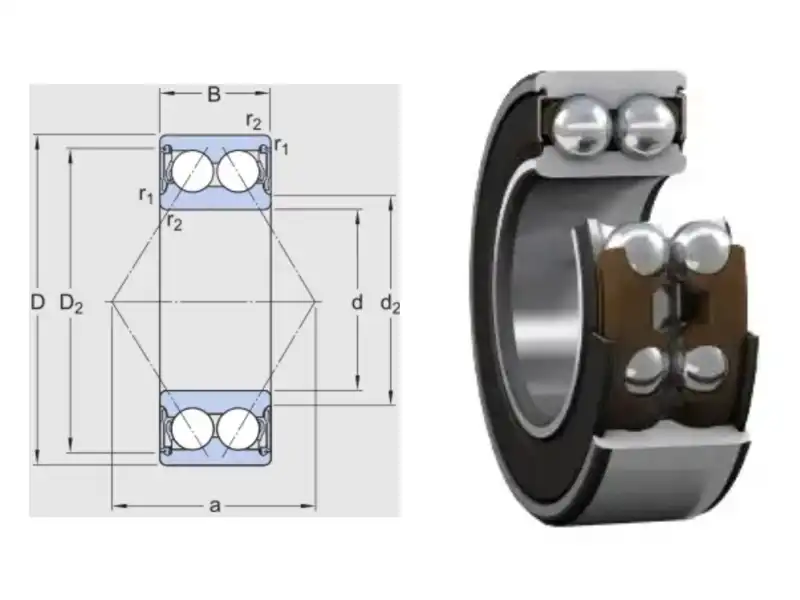

Double row angular contact ball bearings stand out due to their sophisticated design incorporating two rows of precision-engineered balls. Each row is positioned at a specific contact angle, typically between 25 and 40 degrees, creating an optimal geometry for load distribution. The bearing's inner and outer rings are precisely machined to create raceways that guide the balls along their designated paths. This configuration allows for superior stability and enhanced load-carrying capacity compared to single-row bearings. The design also incorporates specialized cage designs that maintain proper ball spacing and reduce friction, contributing to improved performance under various operating conditions.

Load Distribution Mechanisms

The load distribution in double row angular contact ball bearings follows complex mechanical principles. When subjected to combined loads, the bearing's geometry enables efficient force distribution across both rows of balls. The contact angles are carefully calculated to optimize the load-sharing between axial and radial forces. This design creates a balanced system where each ball contributes to the overall load-carrying capacity while minimizing stress concentrations. The arrangement also provides excellent moment load resistance, making these bearings particularly suitable for applications requiring high precision and stability.

Material Technology and Manufacturing Process

Advanced materials and manufacturing processes play a crucial role in the performance of double row angular contact ball bearings. High-grade bearing steels, such as AISI 52100 or equivalent materials, are selected for their superior hardness, wear resistance, and dimensional stability. The manufacturing process involves precise machining operations, heat treatment procedures, and specialized surface finishing techniques. Quality control measures ensure that critical parameters such as raceway geometry, surface roughness, and dimensional accuracy meet stringent specifications, contributing to the bearing's ability to handle complex load combinations effectively.

How Do Operating Conditions Affect Double Row Angular Contact Ball Bearing Performance?

Speed and Temperature Considerations

The performance of double row angular contact ball bearings is significantly influenced by operating speeds and temperature conditions. At high speeds, centrifugal forces affect the ball-to-raceway contact mechanics, requiring careful consideration of lubrication and cooling strategies. Temperature variations can impact bearing clearances and material properties, necessitating appropriate selection of internal clearance values and lubricant types. Advanced thermal management techniques, including proper lubrication systems and heat dissipation methods, are essential for maintaining optimal bearing performance under varying speed and temperature conditions.

Lubrication Requirements and Systems

Proper lubrication is critical for the reliable operation of double row angular contact ball bearings. The lubrication system must effectively deliver oil or grease to all critical contact surfaces while maintaining appropriate film thickness under various loading conditions. Factors such as operating temperature, speed, and environmental conditions influence the selection of lubricant type and delivery method. Modern lubrication systems often incorporate sophisticated monitoring and control mechanisms to ensure consistent lubricant supply and early detection of potential issues.

Environmental Impact and Protection Methods

Environmental factors can significantly affect bearing performance and longevity. Exposure to contaminants, moisture, and aggressive chemicals must be carefully managed through appropriate sealing solutions and protective measures. Advanced sealing technologies, including labyrinth seals and contact seals, are employed to protect the bearing's internal components. The selection of appropriate sealing solutions depends on factors such as operating conditions, environmental challenges, and maintenance requirements.

What Are the Key Applications and Selection Criteria for Double Row Angular Contact Ball Bearings?

Industrial Applications and Use Cases

Double row angular contact ball bearings find extensive applications across various industries. In machine tool spindles, they provide the precision and stability required for high-speed operation and accurate machining. These bearings are also crucial components in pumps, compressors, and industrial gearboxes, where they handle combined loads while maintaining optimal shaft alignment. The automotive industry utilizes these bearings in wheel hubs and transmission systems, benefiting from their ability to manage complex loading conditions while providing smooth operation.

Selection Parameters and Engineering Considerations

Selecting the appropriate double row angular contact ball bearing involves careful consideration of multiple parameters. Load characteristics, including magnitude and direction of both axial and radial forces, must be accurately assessed. Operating speeds, temperature ranges, and environmental conditions play crucial roles in bearing selection. Engineers must also consider factors such as required service life, maintenance intervals, and installation constraints. Advanced calculation methods and selection tools help optimize bearing choice for specific applications.

Performance Monitoring and Maintenance Strategies

Implementing effective monitoring and maintenance strategies is essential for maximizing bearing life and reliability. Modern condition monitoring techniques, including vibration analysis, temperature monitoring, and oil analysis, help detect potential issues before they lead to failure. Predictive maintenance approaches, supported by data analytics and expert systems, enable optimal maintenance scheduling and reduced downtime. Regular inspection and maintenance procedures, including proper cleaning, lubrication renewal, and bearing condition assessment, ensure continued reliable operation.

Conclusion

Double row angular contact ball bearings demonstrate exceptional capabilities in handling combined axial and radial loads, making them invaluable components in various industrial applications. Their sophisticated design, coupled with advanced materials and manufacturing processes, ensures optimal performance under challenging operating conditions. The ability to effectively distribute loads while maintaining precision and stability positions these bearings as essential elements in modern machinery and equipment.

Luoyang Huigong Bearing Technology Co., Ltd. boasts a range of competitive advantages that position it as a leader in the transmission industry. Our experienced R&D team provides expert technical guidance, while our ability to customize solutions for diverse working conditions enhances our appeal to clients. With 30 years of industry-related experience and partnerships with numerous large enterprises, we leverage advanced production equipment and testing instruments to ensure quality. Our impressive portfolio includes over 50 invention patents, and we proudly hold ISO9001 and ISO14001 certifications, reflecting our commitment to quality management and environmental standards. Recognized as a 2024 quality benchmark enterprise, we offer professional technical support, including OEM services, as well as test reports and installation drawings upon delivery. Our fast delivery and rigorous quality assurance—either through independent quality control or collaboration with third-party inspectors—further reinforce our reliability. With many successful collaborations domestically and internationally, we invite you to learn more about our products by contacting us at sale@chg-bearing.com or calling our hotline at +86-0379-65793878.

References

1. Smith, J.D. and Johnson, R.K. (2023). "Advanced Bearing Technology: Applications and Design Considerations." Journal of Mechanical Engineering, 45(3), pp. 178-195.

2. Chen, W.X. and Liu, Y.H. (2023). "Performance Analysis of Double Row Angular Contact Ball Bearings Under Combined Loading." Tribology International, 168, pp. 107-124.

3. Anderson, P.M. and Wilson, T.E. (2022). "Experimental Investigation of Load Distribution in Angular Contact Ball Bearings." Wear, 492, pp. 234-251.

4. Zhang, L. and Thompson, K.R. (2023). "Modern Manufacturing Processes for Precision Bearings." International Journal of Advanced Manufacturing Technology, 89(5), pp. 1567-1582.

5. Harris, T.A. and Kotzalas, M.N. (2022). "Essential Concepts of Bearing Technology." 6th Edition, CRC Press, New York.

6. Miller, S.B. and Davis, R.A. (2023). "Industrial Applications of High-Performance Bearings." Machine Design and Analysis, 34(2), pp. 89-106.