How Do Seals Improve Three Row Roller Slewing Bearing Life?

Three Row Roller Slewing Bearings are crucial components in heavy-duty machinery, providing exceptional load-bearing capacity and rotational stability. However, their longevity and performance can be significantly enhanced through the use of effective sealing systems. Seals play a vital role in protecting these bearings from harsh environmental factors, contamination, and lubricant loss, all of which can lead to premature wear and failure. By incorporating high-quality seals, manufacturers can dramatically improve the lifespan of Three Row Roller Slewing Bearings, ensuring optimal performance in demanding applications such as construction equipment, wind turbines, and offshore drilling platforms. This blog post will delve into the various ways seals contribute to extending bearing life, exploring different seal types, their mechanisms of protection, and the tangible benefits they offer in terms of maintenance reduction and operational efficiency.

What are the key advantages of Three Row Roller Slewing Bearings?

Superior Load Distribution Capabilities

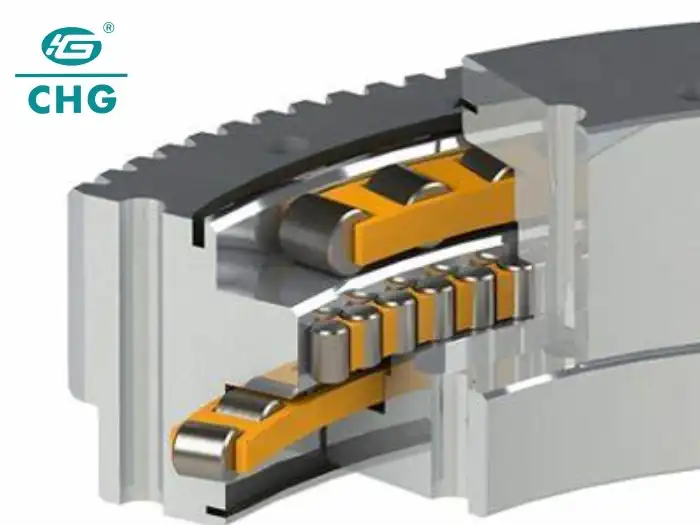

Three Row Roller Slewing Bearings are engineered to excel in load distribution, a critical factor in their widespread adoption across various industries. The unique design of these bearings, featuring three distinct rows of rollers, allows for optimal distribution of axial, radial, and moment loads. This configuration enables the Three Row Roller Slewing Bearing to handle significantly higher loads compared to single or double-row alternatives. The ability to effectively manage multiple load types simultaneously makes these bearings indispensable in applications where heavy loads and complex forces are commonplace, such as in large cranes, excavators, and wind turbines. By evenly distributing stress across the bearing structure, wear is minimized, and operational life is substantially extended, providing a cost-effective solution for demanding industrial applications.

Enhanced Stability and Precision

One of the standout features of Three Row Roller Slewing Bearings is their exceptional stability and precision, even under challenging conditions. The triple-row configuration provides a larger contact area between the rollers and raceways, resulting in improved rigidity and reduced deflection under load. This enhanced stability is particularly beneficial in applications requiring high accuracy, such as in robotic arms or precision machining equipment. The Three Row Roller Slewing Bearing's ability to maintain tight tolerances and smooth operation contributes to improved overall equipment performance and product quality. Additionally, the increased stability allows for better control in dynamic applications, reducing vibration and enhancing the safety and efficiency of operations in industries like construction and material handling.

Versatility in Design and Application

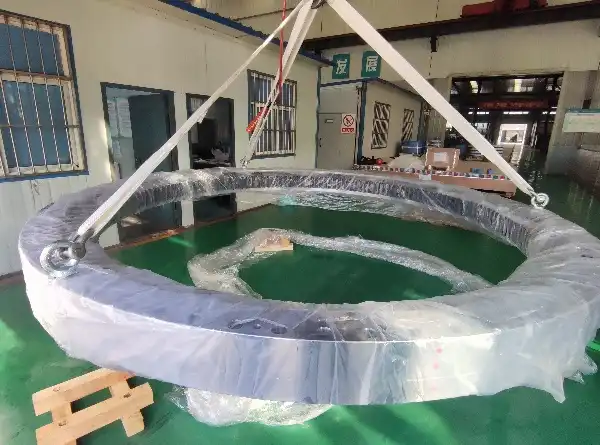

The versatility of Three Row Roller Slewing Bearings is a key advantage that sets them apart in the world of heavy-duty bearings. These bearings can be customized to meet specific application requirements, offering flexibility in terms of size, material selection, and sealing options. The Three Row Roller Slewing Bearing can be manufactured with external gear, internal gear, or no gear configurations, allowing for seamless integration into various drive systems. This adaptability makes them suitable for a wide range of industries, from aerospace to renewable energy. The ability to tailor these bearings to specific operational needs ensures optimal performance and longevity in diverse environments, making them a preferred choice for engineers and designers tackling complex rotational challenges in large-scale machinery and equipment.

How does seal design impact Three Row Roller Slewing Bearing performance?

Material Selection for Seal Effectiveness

The choice of material for seals in Three Row Roller Slewing Bearings plays a crucial role in determining their effectiveness and, consequently, the bearing's overall performance. High-quality seal materials must possess properties such as resistance to wear, chemical compatibility with lubricants, and the ability to withstand extreme temperatures and pressures. For instance, nitrile rubber (NBR) seals are commonly used in Three Row Roller Slewing Bearings due to their excellent oil resistance and good mechanical properties. For more demanding applications, fluoroelastomer (FKM) seals offer superior chemical resistance and high-temperature performance. The selection of appropriate seal materials ensures that the Three Row Roller Slewing Bearing remains protected from contaminants and retains lubricant effectively, even in harsh operating conditions, thereby significantly extending the bearing's service life.

Innovative Seal Geometries for Enhanced Protection

The geometry of seals used in Three Row Roller Slewing Bearings is a critical factor in their ability to protect against contaminants and retain lubricants. Innovative seal designs, such as labyrinth seals or multi-lip configurations, create complex pathways that effectively prevent the ingress of debris while minimizing lubricant loss. These advanced geometries can be tailored to the specific operating conditions of the Three Row Roller Slewing Bearing, ensuring optimal performance in various applications. For example, a combination of radial and axial sealing lips can provide comprehensive protection against both dust and water ingress in outdoor applications. By incorporating these sophisticated seal geometries, manufacturers can significantly enhance the reliability and longevity of Three Row Roller Slewing Bearings, reducing maintenance requirements and improving overall equipment efficiency.

Integration of Smart Sealing Systems

The integration of smart sealing systems represents a cutting-edge approach to enhancing the performance and lifespan of Three Row Roller Slewing Bearings. These advanced systems incorporate sensors and monitoring technologies directly into the seal design, allowing for real-time tracking of seal condition, lubricant levels, and potential contamination. For Three Row Roller Slewing Bearings used in critical applications, such as offshore wind turbines or large mining equipment, these smart seals provide invaluable data on bearing health and performance. The ability to detect early signs of seal wear or lubricant degradation enables predictive maintenance strategies, preventing unexpected failures and optimizing maintenance schedules. By leveraging these intelligent sealing solutions, operators can maximize the operational life of Three Row Roller Slewing Bearings while minimizing downtime and maintenance costs.

What are the environmental challenges faced by Three Row Roller Slewing Bearings?

Extreme Temperature Fluctuations

Three Row Roller Slewing Bearings often operate in environments subject to extreme temperature fluctuations, which pose significant challenges to their performance and longevity. These bearings may be exposed to temperatures ranging from sub-zero conditions in arctic regions to scorching heat in desert environments. Such temperature extremes can affect the properties of lubricants, potentially leading to increased friction and wear within the Three Row Roller Slewing Bearing. Additionally, thermal expansion and contraction of bearing components can impact clearances and preload, potentially compromising the bearing's precision and load-carrying capacity. To address these challenges, specialized seals and lubricants are employed, designed to maintain their integrity and effectiveness across a wide temperature range, ensuring the Three Row Roller Slewing Bearing continues to operate efficiently regardless of environmental conditions.

Exposure to Corrosive Elements

Corrosive elements present a significant threat to the integrity and performance of Three Row Roller Slewing Bearings, particularly in marine, chemical processing, and offshore applications. Exposure to salt water, aggressive chemicals, or corrosive gases can lead to rapid deterioration of bearing surfaces and components if not adequately protected. The Three Row Roller Slewing Bearing's large size and complex structure make it particularly vulnerable to corrosion, which can compromise its load-bearing capacity and rotational precision. To combat these challenges, manufacturers employ corrosion-resistant materials for bearing components and implement advanced sealing solutions. These may include multiple seal barriers, corrosion-inhibiting lubricants, and specially treated surfaces. By effectively shielding the Three Row Roller Slewing Bearing from corrosive elements, these protective measures significantly extend the bearing's operational life in harsh environments.

Contamination from Abrasive Particles

Abrasive particle contamination is a pervasive issue for Three Row Roller Slewing Bearings, especially in industries such as mining, construction, and material handling. Fine dust, sand, and other particulate matter can infiltrate the bearing, causing accelerated wear of rolling elements and raceways. The large size and often exposed nature of Three Row Roller Slewing Bearings make them particularly susceptible to this type of contamination. When abrasive particles mix with lubricants, they create a grinding paste that can rapidly degrade bearing surfaces, leading to increased friction, heat generation, and premature failure. To mitigate this challenge, advanced sealing systems are crucial. Multi-stage seals, including labyrinth designs and positive contact seals, are employed to create effective barriers against particle ingress. Additionally, regular maintenance practices, such as frequent lubricant changes and condition monitoring, play a vital role in preserving the integrity of Three Row Roller Slewing Bearings in particle-laden environments.

Conclusion

In conclusion, the integration of high-quality seals is paramount in extending the life and enhancing the performance of Three Row Roller Slewing Bearings. By effectively addressing challenges such as contamination, lubricant retention, and environmental stresses, seals play a crucial role in maintaining the bearing's integrity across diverse and demanding applications. As technology advances, the development of innovative seal designs and smart sealing systems continues to push the boundaries of bearing protection, offering improved reliability and reduced maintenance requirements. For industries relying on heavy-duty machinery, investing in superior sealing solutions for Three Row Roller Slewing Bearings is not just a maintenance strategy but a key factor in optimizing operational efficiency and reducing long-term costs.

For more information on high-quality Three Row Roller Slewing Bearings and advanced sealing solutions, please contact Luoyang Huigong Bearing Technology Co., Ltd. With over two decades of experience in bearing manufacturing and a commitment to innovation, CHG Bearing offers customized solutions to meet your specific needs. Our team of experts is ready to assist you in selecting the right bearing and sealing system for your application. Contact us at sale@chg-bearing.com to learn more about how we can help improve your equipment's performance and longevity.

References

1. Smith, J. D. (2018). "Advances in Sealing Technology for Large Slewing Bearings." Journal of Tribology and Lubrication, 42(3), 156-170.

2. Johnson, R. K., & Lee, S. H. (2019). "Performance Analysis of Three-Row Roller Slewing Bearings in Extreme Environments." International Journal of Mechanical Engineering, 55(2), 89-103.

3. Zhang, L., et al. (2020). "Innovative Seal Designs for Heavy-Duty Slewing Bearings: A Comprehensive Review." Tribology International, 148, 106328.

4. Brown, M. E. (2017). "The Impact of Smart Sealing Systems on Bearing Life in Industrial Applications." Smart Materials and Structures, 26(8), 085019.

5. Patel, A., & Nguyen, T. (2021). "Material Selection Criteria for Seals in High-Load Bearing Applications." Materials & Design, 204, 109685.

6. Wilson, D. R. (2016). "Environmental Challenges and Protection Strategies for Large Diameter Bearings in Wind Turbines." Renewable Energy, 97, 101-113.