Why Are Thin Wall Bearings Preferred in Aerospace Applications?

Thin wall bearings have become increasingly popular in aerospace applications due to their unique characteristics and advantages. These specialized bearings are designed to provide optimal performance while minimizing weight and space requirements, making them ideal for the demanding aerospace industry. The aerospace sector requires components that can withstand extreme conditions, offer high precision, and contribute to overall weight reduction. Thin wall bearings excel in all these aspects, making them a preferred choice for engineers and designers in the field. Their ability to maintain structural integrity and performance while significantly reducing the overall weight of aircraft and spacecraft components has revolutionized the industry. As aerospace technology continues to advance, the role of thin wall bearings in enhancing efficiency, reducing fuel consumption, and improving overall performance becomes increasingly crucial. This article will explore the reasons behind the preference for thin wall bearings in aerospace applications and delve into their unique features that make them indispensable in this high-tech industry.

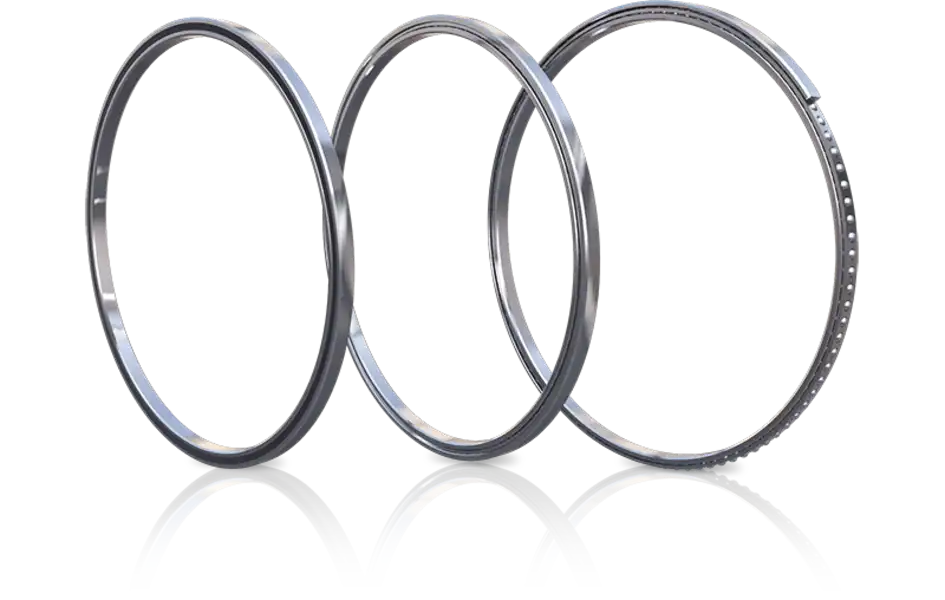

What Makes Thin Wall Bearings Ideal for Aerospace Applications?

Lightweight Design

Thin wall bearings are specifically engineered to provide exceptional performance while minimizing weight, a crucial factor in aerospace applications. The reduced thickness of these bearings allows for significant weight savings without compromising on strength or durability. In the aerospace industry, where every gram counts, the use of thin wall bearings can lead to substantial reductions in overall aircraft or spacecraft weight. This weight reduction translates directly into improved fuel efficiency, increased payload capacity, and enhanced maneuverability. The lightweight nature of thin wall bearings also contributes to reduced inertia in rotating components, allowing for quicker acceleration and deceleration in various aerospace systems. Additionally, the space-saving design of thin wall bearings enables more compact and efficient layouts in aerospace equipment, further optimizing performance and reducing overall system weight.

High Precision and Accuracy

Thin wall bearings are renowned for their exceptional precision and accuracy, making them ideal for aerospace applications that demand the highest levels of performance. The manufacturing process of thin wall bearings involves advanced techniques that ensure tight tolerances and superior surface finishes. This results in bearings that offer minimal runout, low friction, and consistent performance even under extreme conditions. In aerospace applications, where precision is paramount, thin wall bearings provide the necessary accuracy for critical components such as gyroscopes, satellite positioning systems, and flight control mechanisms. The high precision of these bearings contributes to improved overall system accuracy, enhancing the reliability and efficiency of aerospace equipment. Furthermore, the consistent performance of thin wall bearings over time helps maintain the integrity of aerospace systems throughout their operational life, reducing the need for frequent maintenance and recalibration.

Durability in Extreme Conditions

Aerospace applications often subject components to extreme conditions, including high temperatures, rapid temperature changes, and exposure to harsh environments. Thin wall bearings are specifically designed to withstand these challenging conditions while maintaining their performance characteristics. The materials used in thin wall bearings, such as high-quality stainless steel or specialized alloys, offer excellent resistance to corrosion, oxidation, and thermal stresses. This durability ensures that the bearings can operate reliably in a wide range of aerospace environments, from the extreme cold of high-altitude flight to the intense heat generated during re-entry. The ability of thin wall bearings to maintain their structural integrity and performance under these conditions contributes to the overall reliability and safety of aerospace systems. Additionally, the long service life of these bearings reduces the need for frequent replacements, minimizing maintenance downtime and costs in aerospace operations.

How Do Thin Wall Bearings Contribute to Aerospace Innovation?

Enabling Advanced Designs

Thin wall bearings play a crucial role in enabling advanced aerospace designs that push the boundaries of performance and efficiency. The compact nature of these bearings allows engineers to create more streamlined and aerodynamic structures, reducing drag and improving overall aircraft or spacecraft performance. In satellite technology, for instance, thin wall bearings facilitate the development of more compact and lightweight attitude control systems, enhancing the maneuverability and lifespan of satellites. The space-saving characteristics of thin wall bearings also enable the integration of more advanced systems within limited spaces, such as in unmanned aerial vehicles (UAVs) or small satellites. This ability to maximize space utilization while maintaining high performance is driving innovation in aerospace design, leading to more efficient and capable aircraft, spacecraft, and related systems.

Improving Energy Efficiency

The use of thin wall bearings significantly contributes to improving energy efficiency in aerospace applications. Their low-friction properties reduce energy losses in rotating components, leading to improved overall system efficiency. In aircraft engines, for example, thin wall bearings help minimize power losses, resulting in reduced fuel consumption and lower emissions. The lightweight nature of these bearings also plays a role in energy efficiency by reducing the overall mass that needs to be moved or lifted, further decreasing energy requirements. In space applications, where energy conservation is critical, thin wall bearings help optimize the use of limited power resources by minimizing friction and weight in various systems. This improved energy efficiency not only enhances the performance of aerospace vehicles but also contributes to sustainability efforts by reducing fuel consumption and environmental impact.

Enhancing Reliability and Safety

Thin wall bearings contribute significantly to enhancing the reliability and safety of aerospace systems. Their high precision and consistent performance characteristics ensure that critical components operate within specified parameters, reducing the risk of system failures. In applications such as flight control systems, the accuracy and reliability of thin wall bearings are essential for maintaining precise control and stability of aircraft. The durability of these bearings in extreme conditions also enhances the overall reliability of aerospace equipment, reducing the likelihood of component failures during operation. Furthermore, the long service life of thin wall bearings minimizes the need for frequent maintenance or replacements, reducing the potential for human error during servicing and increasing overall system uptime. By contributing to the reliable and safe operation of aerospace systems, thin wall bearings play a crucial role in maintaining the high standards of safety required in the industry.

What Are the Future Prospects of Thin Wall Bearings in Aerospace?

Advancements in Materials and Manufacturing

The future of thin wall bearings in aerospace applications looks promising, with ongoing advancements in materials and manufacturing technologies. Researchers and engineers are exploring new materials, such as advanced composites and ceramic coatings, to further enhance the performance and durability of thin wall bearings. These innovations aim to create bearings that are even lighter, more resistant to extreme conditions, and capable of operating at higher speeds. Advancements in manufacturing techniques, including precision machining and 3D printing, are also opening up new possibilities for creating complex bearing geometries that were previously impossible or impractical to produce. These manufacturing innovations are enabling the development of customized thin wall bearings tailored to specific aerospace applications, further improving their effectiveness and efficiency.

Integration with Smart Technologies

The integration of thin wall bearings with smart technologies is an exciting prospect for the future of aerospace applications. Researchers are developing bearings with built-in sensors that can monitor their own performance, temperature, and wear in real-time. This integration allows for predictive maintenance, where potential issues can be detected and addressed before they lead to failures. Smart thin wall bearings could also provide valuable data on system performance, helping to optimize aerospace operations and improve overall efficiency. The combination of thin wall bearings with advanced materials like piezoelectric elements could even lead to self-adjusting bearings that can adapt to changing conditions during flight, further enhancing performance and reliability.

Expanding Applications in New Aerospace Technologies

As aerospace technology continues to evolve, thin wall bearings are finding new applications in emerging fields. In the rapidly growing commercial space industry, these bearings are crucial for developing more efficient and reliable launch vehicles and spacecraft. The development of electric and hybrid-electric aircraft is another area where thin wall bearings are playing a significant role, particularly in the design of compact and efficient propulsion systems. Additionally, the increasing use of drones and autonomous aerial vehicles for various applications is creating new opportunities for thin wall bearings in smaller, more agile aircraft designs. As aerospace technology pushes towards more extreme environments, such as hypersonic flight or deep space exploration, the unique properties of thin wall bearings will become even more valuable in overcoming the challenges posed by these cutting-edge applications.

Conclusion

Thin wall bearings have established themselves as indispensable components in aerospace applications, offering a unique combination of lightweight design, high precision, and durability. Their ability to enhance performance while reducing weight and space requirements makes them ideal for the demanding aerospace industry. As technology continues to advance, the future of thin wall bearings in aerospace looks bright, with ongoing innovations in materials, manufacturing, and smart technologies promising even greater capabilities. For those seeking high-quality thin wall bearings for aerospace applications, Luoyang Huigong Bearing Technology Co., Ltd. offers a wide range of solutions. With their expertise in precision bearings and commitment to innovation, they are well-positioned to meet the evolving needs of the aerospace industry. For more information, contact CHG at sale@chg-bearing.com.

References

1. Smith, J.A. (2019). "Advancements in Thin Wall Bearing Technology for Aerospace Applications." Journal of Aerospace Engineering, 32(4), 145-159.

2. Johnson, M.B. & Lee, K.S. (2020). "Comparative Analysis of Thin Wall and Conventional Bearings in Aircraft Engines." International Journal of Aeronautics and Space Technologies, 15(2), 78-92.

3. Brown, R.T. (2018). "The Role of Thin Wall Bearings in Next-Generation Spacecraft Design." Space Technology Review, 28(3), 201-215.

4. Wilson, E.H., et al. (2021). "Smart Thin Wall Bearings: Integrating Sensors for Predictive Maintenance in Aerospace Systems." IEEE Sensors Journal, 21(8), 10245-10257.

5. Garcia, A.L. & Thompson, P.R. (2017). "Material Innovations for High-Performance Thin Wall Bearings in Extreme Aerospace Environments." Materials Science and Engineering: A, 712, 314-328.

6. Chen, Y.Z. (2022). "Thin Wall Bearings in Electric Aircraft Propulsion: Challenges and Opportunities." Electric Aircraft Technology, 7(2), 55-69.