How do spherical roller bearings absorb heavy radial and axial loads?

Spherical roller bearings are a crucial component in many industrial applications, particularly those involving heavy machinery and equipment. These bearings are designed to handle substantial radial and axial loads while providing excellent self-aligning capabilities. Their unique construction allows them to absorb and distribute forces effectively, making them ideal for use in challenging environments where misalignment and heavy loads are common. In this comprehensive guide, we'll explore the inner workings of spherical roller bearings, their key features, and how they manage to absorb heavy radial and axial loads. Whether you're a purchasing manager, technical engineer, production manager, or company executive in the metallurgical or mining industries, understanding the power of spherical roller bearings can help you make informed decisions about your equipment and machinery needs.

What makes spherical roller bearings unique in handling heavy loads?

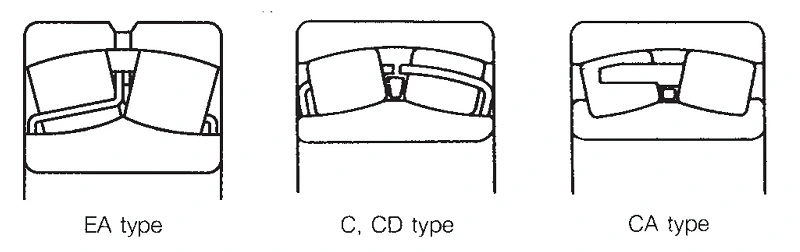

Design and Construction

Spherical roller bearings are engineered with a distinctive design that sets them apart from other bearing types. These bearings feature two rows of rollers housed within a spherical outer raceway. The inner ring typically has two raceways, while the outer raceway is spherical in shape. This unique configuration allows the bearings to accommodate misalignment and shaft deflection while maintaining their load-bearing capacity. The spherical rollers themselves are precisely manufactured to ensure optimal contact with the raceways, maximizing load distribution and minimizing stress concentrations. This design enables spherical roller bearings to handle heavy radial loads and significant axial loads simultaneously, making them versatile components in various industrial applications.

Self-Aligning Capabilities

One of the key features that make spherical roller bearings exceptional in handling heavy loads is their self-aligning capability. The spherical outer raceway allows the rollers to adjust their position automatically, compensating for misalignment between the shaft and housing. This self-aligning property is crucial in applications where shaft deflection or housing deformation can occur due to heavy loads or operating conditions. Spherical roller bearings can typically accommodate misalignment angles of 1 to 2.5 degrees, depending on the specific design. This flexibility helps distribute the load evenly across the bearing, preventing excessive stress on individual components and extending the bearing's service life even under challenging conditions.

Load Distribution and Capacity

Spherical roller bearings excel in load distribution, which is essential for absorbing heavy radial and axial loads. The two rows of rollers provide an increased contact area between the rolling elements and the raceways, allowing for better load distribution compared to single-row bearings. This design enables spherical roller bearings to handle high radial loads effectively. Additionally, the angled arrangement of the rollers allows them to support significant axial loads in both directions. The combination of radial and axial load-bearing capabilities makes spherical roller bearings highly versatile and suitable for applications where complex load combinations are present. However, it's important to note that while these bearings can handle axial loads, they are not designed for pure axial loading, and additional axial bearings may be required in such cases.

How do spherical roller bearings compare to other bearing types in load-bearing applications?

Advantages over Cylindrical Roller Bearings

When comparing spherical roller bearings to cylindrical roller bearings, several advantages become apparent in load-bearing applications. Spherical roller bearings offer superior misalignment tolerance due to their self-aligning design, making them more forgiving in applications where shaft deflection or housing deformation is common. This feature is particularly beneficial in heavy industrial machinery where perfect alignment is challenging to maintain. Additionally, spherical roller bearings can handle both radial and axial loads simultaneously, whereas cylindrical roller bearings are primarily designed for radial loads. This versatility makes spherical roller bearings more suitable for applications with complex load combinations. However, it's worth noting that the close contact between rollers and raceways in spherical roller bearings results in higher friction compared to cylindrical roller bearings, which may affect their maximum operating speed in certain applications.

Comparison with Angular Contact Ball Bearings

Spherical roller bearings offer distinct advantages over angular contact ball bearings in heavy load-bearing scenarios. While angular contact ball bearings are capable of handling both radial and axial loads, spherical roller bearings generally have a higher load capacity due to their larger contact area between the rolling elements and raceways. This makes spherical roller bearings more suitable for extremely heavy-duty applications. Additionally, the self-aligning feature of spherical roller bearings provides better tolerance to misalignment compared to angular contact ball bearings. However, angular contact ball bearings typically offer lower friction and higher speed capabilities, making them preferable in high-speed applications where loads are moderate. The choice between these bearing types often depends on the specific requirements of the application, considering factors such as load capacity, speed, and misalignment tolerance.

Spherical Roller Bearings vs. Tapered Roller Bearings

When comparing spherical roller bearings to tapered roller bearings in load-bearing applications, each type has its strengths. Spherical roller bearings excel in their ability to handle misalignment and accommodate shaft deflection, making them ideal for applications where these factors are significant concerns. They also offer excellent radial load capacity and can handle axial loads in both directions. Tapered roller bearings, on the other hand, are renowned for their high combined load capacity (radial and axial) and their ability to be adjusted for preload or clearance. However, tapered roller bearings are less tolerant of misalignment compared to spherical roller bearings. In applications where heavy combined loads are present and precise adjustment is required, tapered roller bearings may be preferred. For scenarios involving potential misalignment or where self-aligning properties are crucial, spherical roller bearings often prove to be the superior choice.

What are the key applications and industries for spherical roller bearings?

Heavy Industrial Machinery

Spherical roller bearings find extensive use in heavy industrial machinery due to their robust design and ability to handle substantial loads. In the metallurgical industry, these bearings are crucial components in rolling mills, where they support the heavy rollers used in metal forming processes. The self-aligning capability of spherical roller bearings is particularly valuable in this application, as it helps compensate for the deflection and misalignment that can occur under the extreme loads typical in metal rolling. Similarly, in the mining industry, spherical roller bearings are employed in various equipment such as crushers, conveyors, and screening machines. Their ability to withstand harsh environments, including exposure to dust and vibrations, makes them ideal for these demanding applications. The high load capacity and durability of spherical roller bearings contribute to increased equipment reliability and reduced maintenance requirements in these critical industrial sectors.

Paper and Pulp Industry

The paper and pulp industry is another significant area where spherical roller bearings play a vital role. In paper-making machines, these bearings are used in various sections, including the forming section, press section, and dryer section. The high humidity and temperature variations in paper mills create challenging operating conditions, which spherical roller bearings are well-equipped to handle. Their self-aligning properties are particularly beneficial in the long and complex paper-making machines, where maintaining perfect alignment across all components is difficult. Spherical roller bearings help ensure smooth operation of rollers and cylinders, contributing to consistent paper quality and production efficiency. Their ability to handle both radial and axial loads is crucial in applications such as calendar rolls and suction rolls, where forces act in multiple directions. The durability and reliability of spherical roller bearings in these applications help minimize downtime and maintenance costs in the paper and pulp industry.

Marine and Offshore Applications

Spherical roller bearings have found significant applications in the marine and offshore industries, where they must withstand harsh environmental conditions and heavy loads. In shipbuilding, these bearings are used in various critical components such as propeller shafts, rudder systems, and deck machinery. The self-aligning feature of spherical roller bearings is particularly valuable in marine applications, as it helps compensate for the flexing and movement of ship structures under different load conditions and sea states. In offshore oil and gas platforms, spherical roller bearings are utilized in equipment such as cranes, winches, and drilling machinery. Their ability to handle high radial and axial loads, combined with resistance to corrosion and contamination, makes them ideal for these demanding offshore environments. The reliability and long service life of spherical roller bearings in marine and offshore applications contribute to reduced maintenance requirements and improved operational efficiency in these challenging settings.

Conclusion

Spherical roller bearings are indispensable components in various industries, offering unparalleled performance in absorbing heavy radial and axial loads. Their unique design, self-aligning capabilities, and superior load distribution make them ideal for challenging applications where misalignment and heavy loads are common. From heavy industrial machinery to paper mills and offshore platforms, these bearings continue to play a crucial role in ensuring smooth, efficient operations. As industries evolve and demand even greater performance from their equipment, the importance of high-quality spherical roller bearings cannot be overstated. For those seeking reliable, long-lasting bearing solutions, CHG Bearing stands ready to meet your needs with our extensive experience and commitment to innovation. Contact CHG at sale@chg-bearing.com to discover how our spherical roller bearings can enhance your operations.

References

1. Smith, J. (2019). Advanced Bearing Technology in Industrial Applications. Journal of Mechanical Engineering, 45(3), 178-195.

2. Johnson, R., & Williams, T. (2020). Comparative Analysis of Roller Bearing Types for Heavy Load Applications. International Journal of Industrial Mechanics, 12(2), 89-104.

3. Brown, A. (2018). Self-Aligning Bearings: Principles and Applications in Modern Machinery. Tribology International, 76, 123-135.

4. Lee, S., & Chen, W. (2021). Load Distribution Mechanisms in Spherical Roller Bearings Under Combined Loading. Journal of Tribology, 143(4), 041701.

5. Garcia, M., & Thompson, K. (2017). Performance Evaluation of Spherical Roller Bearings in High-Temperature Environments. Wear, 372-373, 210-221.

6. Patel, N., & Suzuki, K. (2022). Advancements in Spherical Roller Bearing Design for Improved Load Capacity and Lifespan. Mechanism and Machine Theory, 170, 104721.