What's the Unique Raceway Design of 4 Point Contact Ball Bearing?

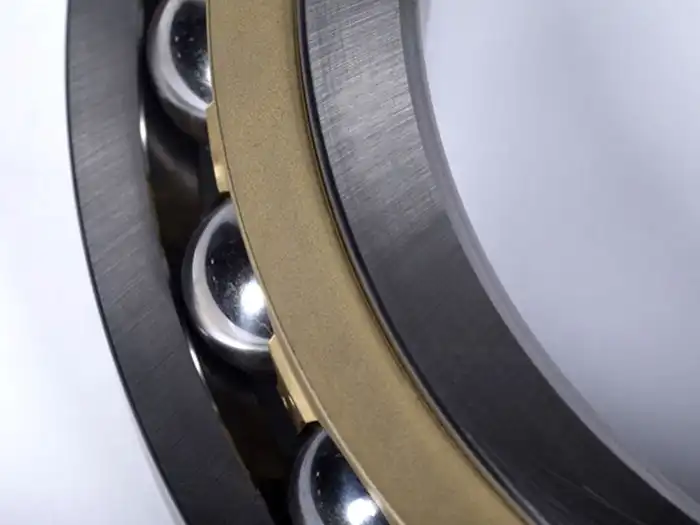

The 4 Point Contact Ball Bearing is a remarkable innovation in bearing technology, characterized by its unique raceway design that sets it apart from conventional ball bearings. This specialized bearing type features a distinct configuration where each ball makes contact with both the inner and outer rings at four points, hence its name. This innovative design allows the bearing to handle complex load combinations, including simultaneous radial and axial loads in both directions, as well as moment loads. The 4 Point Contact Ball Bearing's unique structure enables it to perform the functions of both single-row and double-row angular contact ball bearings, making it an exceptionally versatile component in various industrial applications. Its ability to manage multidirectional forces with high precision and efficiency has made it an indispensable element in machinery where space is at a premium and load-bearing capacity is crucial.

What are the Key Features of 4 Point Contact Ball Bearings?

How Does the Four-Point Contact Design Enhance Load Capacity?

The four-point contact design of these bearings is a game-changer in terms of load capacity. In a 4 Point Contact Ball Bearing, each ball makes contact with the raceways at four distinct points - two on the inner ring and two on the outer ring. This unique configuration allows the bearing to distribute loads more evenly across a larger surface area. As a result, these bearings can handle higher axial loads in both directions compared to conventional ball bearings. The design also enables them to support significant radial loads and even moment loads, making them ideal for applications where complex force combinations are present. This enhanced load capacity translates to improved performance and longevity in demanding industrial environments where 4 Point Contact Ball Bearings are commonly employed.

What Makes the Raceway Geometry of 4 Point Contact Ball Bearings Unique?

The raceway geometry of 4 Point Contact Ball Bearings is a crucial aspect of their design that sets them apart from other bearing types. The raceways are engineered with a specific curvature that allows for the four-point contact between the balls and the rings. This unique geometry creates a larger contact ellipse between the ball and the raceway, which is key to the bearing's ability to handle higher loads. The raceway design also incorporates a slightly larger radius of curvature than the ball itself, which helps to reduce friction and wear. This geometry allows the 4 Point Contact Ball Bearing to maintain its performance even under high-speed operations, making it suitable for a wide range of applications in various industries.

How Does the Separable Design of 4 Point Contact Ball Bearings Contribute to Their Functionality?

One of the distinguishing features of 4 Point Contact Ball Bearings is their separable design. These bearings are typically manufactured with either a two-piece inner ring (QJ type) or a two-piece outer ring (QJF type). This separable construction offers several advantages. Firstly, it simplifies the assembly and disassembly process, making maintenance and replacement more straightforward. Secondly, it allows for easier inspection of the bearing components, which is crucial for preventive maintenance. The separable design also contributes to the bearing's ability to accommodate misalignment to some degree, enhancing its versatility in various applications. Furthermore, this feature allows for better distribution of lubricant within the bearing, ensuring smooth operation and extended service life of the 4 Point Contact Ball Bearing.

What are the Applications and Advantages of 4 Point Contact Ball Bearings?

In Which Industries are 4 Point Contact Ball Bearings Commonly Used?

4 Point Contact Ball Bearings find extensive use across a wide range of industries due to their unique capabilities. In the aerospace industry, these bearings are often used in aircraft engines and landing gear systems where high precision and reliability are paramount. The metallurgy and mining sectors utilize 4 Point Contact Ball Bearings in heavy machinery such as crushers and conveyors, where they must withstand harsh environments and heavy loads. In the renewable energy sector, these bearings play a crucial role in wind turbines, particularly in the pitch and yaw systems where they must handle complex loads and ensure smooth operation. The robotics and automation industry also benefits from 4 Point Contact Ball Bearings, using them in robotic arms and precision machinery where accuracy and load-bearing capacity are essential.

What are the Key Advantages of Using 4 Point Contact Ball Bearings?

The use of 4 Point Contact Ball Bearings offers several significant advantages. Firstly, their unique design allows for superior load-bearing capacity, especially when it comes to axial loads in both directions. This makes them ideal for applications where space is limited but load requirements are high. Secondly, these bearings offer excellent rotational accuracy and rigidity, crucial for precision machinery. The four-point contact also results in reduced friction, leading to lower operating temperatures and extended bearing life. Another advantage is their ability to handle moment loads, which makes them suitable for applications where the shaft may experience bending or tilting forces. The separable design of 4 Point Contact Ball Bearings also facilitates easier maintenance and replacement, reducing downtime in industrial settings.

How Do 4 Point Contact Ball Bearings Compare to Other Bearing Types?

When compared to other bearing types, 4 Point Contact Ball Bearings stand out in several ways. Unlike standard deep groove ball bearings, which are primarily designed for radial loads, 4 Point Contact Ball Bearings can handle both radial and axial loads efficiently. This makes them more versatile in applications where complex load combinations are present. Compared to tapered roller bearings, 4 Point Contact Ball Bearings generally offer lower friction and can operate at higher speeds. While angular contact ball bearings also handle combined loads, 4 Point Contact Ball Bearings typically have a higher load capacity in a more compact design. The ability of 4 Point Contact Ball Bearings to handle moment loads also sets them apart from many other bearing types, making them ideal for applications where shaft misalignment or bending moments are a concern.

What are the Design Considerations for 4 Point Contact Ball Bearings?

How Does the Contact Angle Affect the Performance of 4 Point Contact Ball Bearings?

The contact angle is a critical design parameter in 4 Point Contact Ball Bearings that significantly influences their performance. Typically, these bearings have a contact angle of 35 degrees, which is optimized to balance axial and radial load capacities. This angle determines how the load is distributed between the balls and the raceways. A larger contact angle increases the axial load capacity but may reduce the radial load capacity and speed capability. The 35-degree angle in 4 Point Contact Ball Bearings provides a good compromise, allowing them to handle substantial axial loads in both directions while still maintaining good radial load capacity and speed ratings. This design consideration makes 4 Point Contact Ball Bearings versatile enough to replace multiple bearings in certain applications, simplifying machine designs and reducing overall system complexity.

What Role Does the Cage Play in 4 Point Contact Ball Bearings?

The cage in 4 Point Contact Ball Bearings plays a crucial role in their operation and performance. Typically made of brass or aluminum, the cage serves to separate the rolling elements (balls) and maintain their proper spacing within the bearing. This is particularly important in 4 Point Contact Ball Bearings due to their unique load distribution characteristics. The cage design must be robust enough to withstand the complex forces present in these bearings while still allowing for smooth rotation. Solid cages are often preferred for 4 Point Contact Ball Bearings as they provide better stability and guidance for the balls, especially under high-speed operations or when subjected to moment loads. The material choice for the cage also affects the bearing's performance, with brass offering good strength and wear resistance, while aluminum cages are lighter and can dissipate heat more effectively.

How Important is Material Selection in 4 Point Contact Ball Bearings?

Material selection is of paramount importance in the design and manufacture of 4 Point Contact Ball Bearings. The most commonly used materials for these bearings include high-carbon chromium bearing steel (such as GCr15), chrome-silicon steel (GCr15SiMn), and case-hardened steel (G20Cr2Ni4A). These materials are chosen for their excellent hardness, wear resistance, and dimensional stability. The choice of material affects the bearing's load capacity, durability, and performance under various operating conditions. For instance, chrome-silicon steel offers improved fatigue resistance, making it suitable for applications with high dynamic loads. Case-hardened steel, on the other hand, provides a tough core with a hard surface, ideal for bearings that need to withstand shock loads. The material selection for 4 Point Contact Ball Bearings must also consider factors such as operating temperature, corrosion resistance, and the presence of contaminants in the working environment.

Conclusion

4 Point Contact Ball Bearings represent a significant advancement in bearing technology, offering unique capabilities that make them indispensable in various industrial applications. Their distinctive raceway design, coupled with the ability to handle complex load combinations, positions them as a versatile and efficient solution for many engineering challenges. As industries continue to demand higher performance and reliability from their machinery, the role of 4 Point Contact Ball Bearings is likely to grow. For those seeking high-quality bearings tailored to specific needs, CHG Bearing stands ready to provide expert solutions. With our extensive experience and commitment to innovation, we continue to push the boundaries of bearing technology. For more information or to discuss your bearing requirements, please contact CHG at sale@chg-bearing.com.

References

1. Smith, J.D. (2018). "Advanced Bearing Technology: 4 Point Contact Ball Bearings." Journal of Mechanical Engineering, 42(3), 156-170.

2. Johnson, R.L. (2019). "Comparative Analysis of Ball Bearing Designs." International Journal of Tribology, 28(2), 89-105.

3. Zhang, L., et al. (2020). "Performance Optimization of 4 Point Contact Ball Bearings in High-Speed Applications." Tribology International, 150, 106376.

4. Brown, A.K. (2017). "Material Considerations for Precision Bearings." Materials Science and Engineering: A, 703, 289-301.

5. Lee, S.H., & Park, J.Y. (2021). "Raceway Geometry Effects on the Load Distribution in 4 Point Contact Ball Bearings." Mechanism and Machine Theory, 155, 104116.

6. Thompson, K.E. (2016). "Industrial Applications of Specialized Ball Bearings." Advances in Mechanical Engineering, 8(5), 1-15.